- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- siemens plc

Results for

Siemens plc - Import export

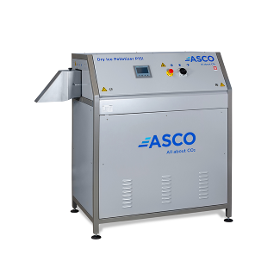

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO Dry Ice Pelletizer P55i is one of the most powerful dry ice machines from ASCO's iSeries line. Having a production capacity of 550 kg/h (1'212 lb/h) it meets the demands for high dry ice quantities plus quality and flexibility in the daily working process. As a model of ASCO's iSeries, it is equipped with stateoftheart remote control devices and thus is ready for a wide range of services in the areas of Remote Access, Remote Data, Remote Management. Be it for fast and efficient trouble shooting and maintenance or for gathering production and performance data the ASCO iSeries offers a wide range of possibilities to link Industry 4.0 with dry ice production. The ASCO Dry Ice Pelletizer P55i is driven by two powerful hydraulic units, which are running independently by the push of a button. This allows the production of identical or different pellet sizes in combination with the offered extruder plates at the same time.

Request for a quote

DANTECHS TECHNOLOGY CONSULTANCY INDUSTRY AND TRADE LTD.

Turkey

Siemens drivers,PLC,motors,I/O boards are available as brand new or refurbished. Siemens components available in stock; 6ES7516-3FN02-0AB0 6ES7515-2FM02-0AB0 6ES7516-3AN02-0AB0 6AV2124-0QC02-0AX1 6ES7515-2AM02-0AB0 6ES73152EH140AB0 6ES7314-6EH04-0AB0 6ES7512-1SK01-0AB0 6AV2124-0MC01-0AX0 6AV2124-0JC01-0AX0 6ES7526-2BF00-0AB0 6GK7543-1AX00-0XE0 6SL3120-2TE21-0AD0 6SL3210-1KE23-8AF1 6SL3120-2TE15-0AD0 6SL3120-2TE13-0AD0

Request for a quote

DANTECHS TECHNOLOGY CONSULTANCY INDUSTRY AND TRADE LTD.

Turkey

6Es7516-3Fn02-0Ab0 Siemens Simatic S7-1500F, Cpu 1516F-3 Pn/Dp, Cpu

Request for a quote

FERPLAST SNC

Italy

Skinpack packing machine at semiautomatic cycle to package objects of either small, medium or large size, between cardboard and transparent plastic film. The skinpack package allow immediate display of the product, possibility of both advertising in colour on the cardboard surfaces, practicality of the packaging, which can be hung in showcases. Safety protection with sensors. The cardboard support can be replaced with a sheet of bubble wrap (bubble polyethylene). CE-approved machine with low voltage controls, electrical panel with Siemens PLC, safety module (Pilz), safety protection on the work area with safety sensor (the movement of the frame descent only occurs with closed protection, the movement of ascent is driven by a dual control). The packaging machine mod. FP-390 has a limited energy consumption as the resistors are activated only at the time of packaging (on the other Skinpacks the resistances are always on) and there is no risk of overheating.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO Dry Ice Pelletizer P15(i) is a compact and powerful dry ice machine from our iSeries line. Having a production capacity of 150 kg/h (331 lb/h) it meets the demands for higher dry ice quantities plus quality and flexibility in the daily working process. As an optional model of ASCO's iSeries, it can be equipped with stateoftheart remote control devices and thus is ready for a wide range of services in the areas of Remote Access, Remote Data, Remote Management. Whether for fast and efficient trouble shooting and maintenance or for gathering production and performance data the ASCO iSeries offers a wide range of possibilities to link Industry 4.0 with dry ice production. The ASCO Dry Ice Pelletizer P15(i) is driven by a powerful hydraulic unit featuring instant push button start. All functions are controlled by a Siemens PLC with touch screen.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO Dry Ice Pelletizer P28i is a compact and powerful dry ice machine from our iSeries line. Having a production capacity of 280 kg/h (617 lb/h) it meets the demands for higher dry ice quantities plus quality and flexibility in the daily working process. As a model of ASCO's iSeries, it is equipped with stateoftheart remote control devices and thus is ready for a wide range of services in the areas of Remote Access, Remote Data, Remote Management. Be it for fast and efficient trouble shooting and maintenance or for gathering production and performance data the ASCO iSeries offers a wide range of possibilities to link Industry 4.0 with dry ice production. The ASCO Dry Ice Pelletizer P28i is driven by a powerful hydraulic unit featuring instant push button start. All functions are controlled by a Siemens PLC with touch screen.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO Dry Ice Reformer R70i has been developed for producing dense dry ice blocks in various sizes by compressing dry ice pellets. Be it in combination with an existing or with a new dry ice pelletizer, the ASCO Dry Ice Reformer R70i is a very convenient tool to complement the dry ice pellet business with dry ice blocks. The compact machine is driven by a powerful and unique hydraulic unit featuring instant push button start. All functions are controlled by a Siemens PLC. A Siemens touch screen provides good overview and easy operation, a comprehensive monitoring, easy maintenance and optimal service planning. An integrated production control system allows to define and supervise the amount of blocks or weight to be produced.

Request for a quote

MERECS ENGINEERING GMBH

Germany

We develop and build test stands for pumps and can refer to several references in this field. In addition, we build press-off facilities and design them individually, including suitable risk assessment. Our process visualisation is suitable for customer presentations of the running pumps directly at the pump test stand. In addition, Merecs Engineering provides the connection to the IT infrastructure of our customers (ERP systems or databases). - Planning, calculations and construction - Coordination of suppliers - LabVIEW software development - NI-Real-Time & FPGA for high-speed evaluation of speed and acceleration measurement values - Vibration analysis via FFT (updated live) - LabVIEW, NI-cRIO and Siemens S7-1500 PLC in combination possible - Database connection - On-site assembly and IB

Request for a quote

FERPLAST SNC

Italy

Rotating platform Mod. FP T 1500 with recess for transpallet insertion, table diameter mm. 1500 and 90° load (only base without column). Following some modifications made to the machines it is no longer possible to have front loading. The pallet must not have the lower sleepers on the insertion side of the pallet truck. In the basic version, for safety reasons, the operator must always keep the button or the footswitch pressed during winding. Releasing it, the rotary table stops randomly, so you must manually align the platform to the unloading position. When ordering, it is possible to purchase the surcharge for the electrical system with PLC LOGO SIEMENS, complete with safety photocell on the pallet load, programming of the number of revolutions, variation of the table speed (inverter) and stop in the unloading position. With this modification the power supply of the table goes from 380V to 220V.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

FULLY AUTOMATIC FILLING, SEALING AND FINISHING SYSTEM, Complete transport format set 12-fold stepped jar transport with mehanical overload coupling Electrical connections for the integration of an inductive sealing unit (see options) Filling unit with turnstyle slide dosage aggregate 40 l filling funnel Electronic volume adjustment Foil dispenser with pre-sealing Thermal conductive sealing unit Automatic central lubrication (low maintenance) Integrates transport belt Protective glazing in aluminium / Makrolon(R) Central cntinuou height adjustment of belts and guides via manual wheel Integrated screwing unit Integrated PLC control Siemens S7

Request for a quote

STEROS GPA INNOVATIVE, S.L.

Spain

A device for emergency ventilation and intensive care that allows to control and monitor the key parameters of ventilation. It has been designed to work continuously and intensively. It has different ventilation modes, giving it great versatility to treat patients in different phases of invasive ventilation. Control by PLC SIEMENS with a very simple and intuitive interface for maximum security. RESPIRA has real-time measurement sensors for key parameters for respiration, respiration graphs.

Request for a quote

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Automatic Sleeve Shrink Wrap Machine is made to wrap heavy products with thick film.The finished packaging has two open ends on each side which are referred to as "bullseyes". Standard products packaged with a shrink bundling machine include firewood, canned goods, cases of water bottles, metal products, tool cases, and more. The machine can carry out two-row, three-row, four-row shrink packaging with or without bottom support,like 10 bottles (1 × 10), (2 × 5), 9 bottles (3 × 3), 12 bottles (3 × 4), 15 bottles (3 × 5), 24 bottles (4 × 6). Using worm gear reducer, products feeding and film feeding smooth without jitter. Adopt "Siemens" "PLC" program controller to realize the integration of machine, electricity and gas.Using worm gear reducer, products feeding and film feeding smooth without jitter.Specially designed sealing knife, the sealing line is firm, not cracked, and not easy to stick to the knife.The frequency converter controls the transmission speed.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Rotary packing machine combine with liquid pump cylinder measurement,accurate measurement, fast speed, low defective rate, low noise,add the reflow system can avoid liquid material leakage. 2. Eight stations rotary design to automatic control of a series of processes from bag-giving, coding,bag-opening, filling, sealing, and finished products. It also automatic-check bag situation, filling and sealing situation to prevent waste of bags and materials. 3. The main configuration is the Siemens PLC control system, simple operation, and easy maintenance. 4. The machine uses premade pouch, you have more choice for the bag type and excellent appearance. 5.Modular heating, more accurate temperature control, heating failure can alarm prompt. 6.Strictly follow the mechanical standards to production, ensure the quality ,reduce late wear, reduce parts replacement. 7.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Rotary packing machine combine with servo auger/agitator feeder system,30-50L fillers,and lifting conveyor,accurate measurement, fast speed, low defective rate, low noise. 2.Eight stations rotary design ,compact and reasonable arranged in the smallest amount of space,to automatic control of a series of processes from bag-giving,coding,bag-opening,filling, sealing, and finished products. It also automatic check bag situation, filling and sealing situation to prevent waste of bags and materials. 3.Adopt Siemens PLC control system, touch screen can set variety of languages,simple operation, and easy maintenance. 4.The machine use premade pouch,you have more choice for the bag type and excellent appearance .Sealing good, the finished product looks high-end. 5.Strictly follow the mechanical standards to production, ensure the quality ,reduce late wear, reduce parts replacement. 6.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.The machine use premade pouch,you have more choice for the bag type and excellent appearance . 2.Eight stations rotary design to automatic control a series of processes from bag-giving,coding,bag-opening,filling, sealing, and finished products. It also automatic check bag situation, filling and sealing situation to prevent waste of bags and materials. 3.The main configuration is Siemens PLC control system,simple operation, and easy maintenance. 4.The speed of this machine is adjusted by frequency conversion with the range, and the actual speed depends on type of products and pouch. 5.Easy to link up with other packaging equipment such as multi-heads weigher, liquid pump filler, auger/agitator fillers, feeding conveyor,platform,the cartoning machine,case sealer etc. 6.Strictly follow the mechanical standards to production, ensure the quality ,reduce late wear, reduce parts replacement. 7.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1.Rotary pouch bagging vacuum packaging machine combine with different fillers,such as weighing machine,liquid pump and auger/agitator fillers, accurate measurement, fast speed, low defective rate, low noise. 2.Eight stations rotary design to automatic control a series of processes from bag-giving,coding,bag-opening,filling,vacuuming,sealing,and finished products. It also automatic check bag situation, filling and sealing situation to prevent waste of bags and materials.Status in the vacuum chamber can be checked through the transparent plastic vacuum shell lids. 3.Adopt Siemens PLC control system, be easily performed operation and maintenance. 4.Filling machine rotates intermittently to fill the product easily and vacuum machine rotates continuously to enable smooth running, it means high performance and high durability.All grippers width of filling machine can be adjusted at once by a motor but all grippers in the vacuum chambers are no need to adjust.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

1. Rotary packing machine combinate with the multi-heads weighing machine, Z-type conveyor, platform, accurate measurement, fast speed, low defective rate, low noise. 2. Eight stations rotary design to automatic control a series of processes from bag-giving, coding,bag-opening, filling, sealing, and finished products. It also automatic-check bag situation, filling and sealing situation to prevent waste of bags and materials. 3. The main configuration is the Siemens PLC control system, simple operation, and easy maintenance. 4. The machine uses premade pouch, you have more choice for the bag type and excellent appearance. 5. The lifting system is suitable for a wide range of industries, like food fodder, chemical, and so on granule material packing. 6. Strictly follow the mechanical standards to production, ensure the quality, reduce late wear, and reduce parts replacement. 7.SUS304 stainless steel is used for the contact part with products to ensure the cleanliness of the product.

Do you sell or make similar products?

Sign up to europages and have your products listed

MOSCA GMBH

Germany

• SoniXs Ultrasonic sealing unit • Strap dispenser • Complete electric control for automatic and semiautomatic operation in the operator panel • Siemens PLC control with touch panel • Different Models: [KZV-311] • Lateral mounted sealing unit • Sealing unit moveable towards the product • Strap lance for strapping of palletised goods [KOV-311] • Like basic model KZV-311, closed strap frame for boxes and cartons

Request for a quote

MOSCA GMBH

Germany

• Inline strapping parallel to flute • SoniXs Ultrasonic needle sealing unit • Automated setup system resets to the dimensions of the first bundle of the new size [Teach-In] • 6-sided electromechanical package alignment • Potential-free contacts to upstream and downstream machines • Siemens PLC control with touch panel • Stand-by-mode reduces wear and energy consumption • Lateral automatic adjustment device • Automatic machine adaptation to package dimensions via adjustable recipes [500] • Sealing unit removing device

Request for a quote

MOSCA GMBH

Germany

• SoniXs Ultrasonic sealing unit • Strap dispenser • Potential-free contacts to upstream and downstream machines • Complete electric control for automatic and semiautomatic operation in the operator panel • Siemens PLC control with operator button Options: • Three-part signal light including low strap detection • HL sealing unit with floating head (up to 5,000 N strap tension) • Cable marking • Chassis with flanged rollers • Chassis for conveying height > 800 mm • Manual scantling device (80 x 80 – 100 x 100 mm)

Request for a quote

MOSCA GMBH

Germany

Inline strapping parallel to flute Thermostatically controlled heat-weld sealing Siemens PLC control with touch panel 5-sided electromechanical package alignment Potential-free contacts to upstream and downstream machines Automated setup system resets to the dimensions of the first bundle of the new size (“Teach-In”) Capability to strap up to 90 mm outside the bundle center (adjustment in steps of 10 or 30 mm) allows for perfect strapping of complex bundle sizes and forms Chassis on rails with mechanical locking [MCB-2 XT]: Two movable sealing units

Request for a quote

MOSCA GMBH

Germany

• Top-mounted SoniXs ultrasonic sealing unit • Automatic height adjustment of pressure plate to bundle height • Easy accessibility • Electrically driven lift plate with geared brake motor • Strap dispenser • Siemens PLC control with touch panel • 2-column design from 2,200 mm passage width Different Models: [KZV-111] • Top-mounted sealing head • One SoniXs- sealing head and one vertical strap guide • Movable strap lance for strapping of palletized goods [KZS-111] Like basic model KZV-111, with laterally moveable turntable [KOV-111] Like basic model KZV-111, with additional underfeed channel for unpalletized goods [KVV-111] Like basic model KZV-111, bottom arch with automatically controlled strap lance or underfeed channel; particularly suitable for strapping of frequently changing package types with or without pallets Options: • Automatic balk feeder with large buffer [KOV] • Angle edge protection for securing sensitive products for transport [KOV]

Request for a quote

MOSCA GMBH

Germany

• Top-mounted SoniXs ultrasonic sealing unit • Up to four strap lances for palletized products • Strap guide distance of 440, 625 and 810 mm • 1 or 2 sealing units laterally movable • Siemens PLC control system • Operation via Siemens 9” touch panel • Can be integrated into any production line • Potential-free contacts to upstream and downstream machines • Strapping with medium compression [up to 30,000 N – version KC_] • Strapping with high compression [up to 50,000 N – version KP_] Different Models: [K_R] Basic Model \ Driven roller conveyor [K_K]-Version \ Driven roller conveyor with lift turncross [K_Z]-Version \ Driven roller conveyor with centering device [K_A]-Version \ Driven roller conveyor with lift turncross and centering device [K_T]-Version \ Driven roller conveyor with turntable [K_S]-Version \ Driven roller conveyor with turntable, laterally moveable

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

nduction Heating and Joining in one turnkey system. This turnkey system is used to heat electric motor housings with various dimensions for a wide range of joining processes. Example Heating System 1: the die-cast aluminium housing for an asynchronous motor (diameter 450 mm) is heated to approx. 290°C in approx. 5 minutes to fit the wound stator package. The parts are loaded and unloaded from the feeding belt parallel to the working time. The heating process takes place in two independent work stations. The generator has a switched output which means that only one generator is required for the two heating stations. The system is controlled using a SIEMENS PLC controller. Example Heating System 2: the aluminium housing (diameter 140 mm) of a synchronous motor is heated to approx. 280°C in approx. 3 minutes to fit the stator. The component is loaded into and unloaded from the heating station semiautomatically. The system is controlled using a PLC.

Request for a quote

ROTAKEM

Turkey

Technicial Specifications: 1. Origin: Germany 2. Manufacturer: Troester 3.Type: r-type inverted array 4. Cylinder dimensions: Ø600 x 1500 mm 5. Roller speed: 3-30 mt / min 6. Cooling: Environmental corrugated watery closed loop system 7.Cooling Unit: With two hoods 8. Bearings: Bronze 9.Transmission: Each mill has independent drive, independent shaft 10. Motor Powers: 65 kW, 1500 rpm 90 kW, 1500 rpm 65 kW, 1500 rpm 11.Open / close: Automatic 12. Siemens PLC & touch screen control system *** All pictures are before revision

Request for a quote

ROTAKEM

Turkey

Technicial Specifications 1. Origin: Germany 2.Manufacturer: WERNER & PFLEIDERER 3. Production year: 1993 4. Year of renewal: 2020 5.Model No: 200 AES 6. Serial No: 231256 7.200 lt net usage volume 8.Hydraulic cover 9. Motor powers: 75 kW; 56 kW 10.Rotor speed: 0-50 rev / min 11.Extruder speed: 0-40rpm 12. Screw diameter: 180 mm 13.PLC & touch screen Siemens control system 14. Stainless steel bowl and rotor

Request for a quote

ZIM MÜHENDISLIK CONCRETE MACHINES

Turkey

ZIM A 2625 machine is designed to increase efficiency for production of pipes and culverts. It has uniqe specifications to increase production capacity, using life, products quality. This machine can produce pipes 800mm – 2600mm diameter and 2500mm height.Machines can be designed semi or full automatic according to requirements. We use SIEMENS brand PLC microprocessors on automatic machines. The vibration system of machine is controlled by frequency driver controll system. It does not need any mechanic settings. It can easily adjusted from operator pannel. The vibrator system specially designed by our R&D team is used in our machines. The cooling of the vibrators are done by oil cycle system. There is a special unit for that cycling process. Oil flow is controlled by special sensors. Thanks to this technology our machines which have been working for many years without any problems, stand out with their low operating costs.

Request for a quote

BALABAN 54 MAKINA DIS.TIC.LTD.STI

Turkey

Capacity: 1000 to10000 Lt / h Drum Rotation: 7250 r/m Drum Drainage Volume: 12 Lt. Drum Material: DIN 1.4462 Dublex Working Tempreture: +4-60 C Input Pressure: 0-2 Bar Cream Output Pressure: 1-2 Bar Milk Output Pressure: 1-4 Bar Working Frequency: 50 hz Engine Power: 15 kw Recommended Ampere: 12 amp Recommended Working Heat: 45-55 °C Water Pump's Engine Power: 0,75 Kw Total Weight: 1150 kg Cream separator has automatic cleaning rotary. Rotary drum is adjusted on control panel and impurity is discharged. Rotary drum works using operation water. Drum has high mecanical durability and is made of Siemens Brand PLC Control Unit, Siemens Brand 6" colourful touch-operated control panel, Siemens brand 15 kw actuator, 650*400*1200mm insulated stainless electrical panel, Platform designed to assemble machine, electrical panel and hydrophore. 0,7 kw stainless, automatic hydrophore.

Request for a quote

TECHNOWAGY LTD

Ukraine

The automatic machine is used for automatic folding up ready cardboxes from cassette, filling it with dosed loose product, gluing and packing it at bottom and top at automatic gluing station. The machine is equipped with a high-quality control system, which consists of the best components from Europe and is based on PLC Siemens. The machine is controlled using a touch-screen installed on the front of the control panel. From this display, you can monitor and configure the operation of the machine. All the parameters (like dose mass, dosing mode etc) are set at one terminal.

Request for a quoteResults for

Siemens plc - Import exportNumber of results

33 ProductsCompany type

Category

- Packing and packaging - machinery and equipment (14)

- Cooling and lubrication pumps (4)

- Forming, rubber - machinery (2)

- Automation - systems and equipment (1)

- Assemblies, hydraulic (1)

- Cardboard and cardboard products - processing machinery (1)

- Centrifugal pumps (1)

- Chemicals and pharmaceuticals - packaging machinery (1)

- Concrete preparing - machinery and equipment (1)

- Electronics - import-export (1)

- Food Processing (1)

- Food extracts - machines and equipment (1)

- Induction heating systems (1)

- Medical Equipment (1)

- Metal industrial presses (1)

- Package stamping machinery (1)

- Scientific research equipment (1)