- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heat sinks for electronics

Results for

Heat sinks for electronics - Import export

AMETEK SPECIALTY METAL PRODUCTS

United States

We specialize in engineering high quality composites for management of heat in electronics packages, particularly Integrated Circuit (IC) packaging. These composite materials are comprised of Molybdenum Copper (AMC) and Tungsten Copper (AWC). Turnkey Solution for Production Ready Pedestals Our advanced thermal management materials are offered both in a raw form such as block or sheet for finished machining at our customers’ facilities or their sub-tier suppliers. We also offer turnkey finished products completed through machining, plating and customer specified packaging. Sizes Our heat spreader materials for IC packages are offered in a wide breadth of sizes including: Standard blocks of 3” (76 mm) x 4” (102 mm) x 12” (304.8mm) Down to finished machined and plated products in 0.015” (0.381mm) cubes Hermetic Housings and Heat Sinks These thermal management products are used as both the hermetic housings and as the expansion-matched

Request for a quote

PRECISION CERAMICS

United Kingdom

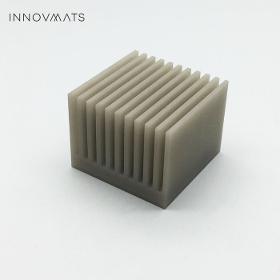

Aluminium nitride (AlN) is one of the best materials to use if high thermal conductivity is required. When combined with its excellent electrical insulation properties, aluminium nitride is an ideal heat sink material for many electrical and electronic applications.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The aluminum nitride (AlN) ceramic has high thermal conductivity(5-10 times as the alumina ceramic), low dielectric constant and dissipation factor, good insulation and excellent mechanical properties, non-toxic, high thermal resistance, chemical resistance ,and the linear expansion coefficient is similar with Si,which is widely used in communication components, high power led, power electronic devices and other fields.Special spec products can be produced upon requests. Product Features 1.Uniform microstructure 2.High thermal conductivity* (70-180 Wm-1K-1), tailored via processing conditions and additives 3.High electrical resistivity 4.Thermal expansion coefficient close to that of Silicon 5.Resistance to corrosion and erosion 6.Excellent thermal shock resistance 7.Chemically stable up to 980°C in H2 and CO2 atmospheres, and in air up to 1380°C (surface oxidation occurs around 780°C; the surface layer protects the bulk up to bulk up to 1380°C).

Request for a quote

SEIFERT ELECTRONIC GMBH

Germany

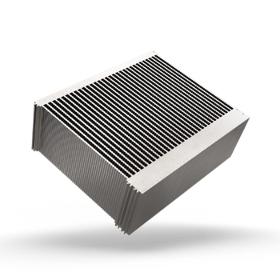

High-performance heat sinks from Seifert electronic are exclusively designed for forced cooling applications. The powerful heat sinks from the Vario and DKL series impress with their large cooling surfaces. Utilizing a finned construction, rib spacing can be manufactured that is not achievable with conventional extruded profiles. Thanks to maximized surface area with the same weight, a high-performance heat sink delivers above-average cooling performance per unit volume. We have patented our proprietary compression geometry at Seifert electronic. In this process, individual fins are precisely cold-pressed into a heat sink without the use of adhesives. Heat conduction in the finned heat sinks occurs directly from the base to the fins, without any thermal transition as seen with pressed-in ribs into a solid base. Custom mounting holes can be incorporated into the pressed, surface-milled base.

Request for a quote

SEIFERT ELECTRONIC GMBH

Germany

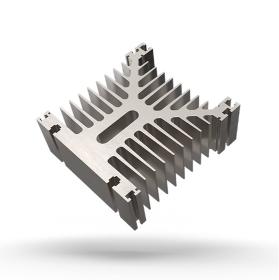

Seifert heat sinks are designed for both natural and forced cooling applications. From standard heat sinks to individually machined custom profiles, we offer the appropriate heat sink in the desired profile. The standard heat sinks from Seifert electronic GmbH are classic finned heat sinks, primarily intended for natural cooling. However, these heat sinks can also be utilized for forced cooling with airflow. Thanks to the extensive variety of profiles in our standard range, we can fulfill almost any heat sink requirement. From small transistor coolers to profile giants for IGBT cooling, measuring up to 900 mm in width, we provide the right profile for nearly every application. In addition to our standard profiles, we have access to open profiles, offering the possibility of further variations without incurring tooling costs.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SEIFERT ELECTRONIC GMBH

Germany

Our thermal management and insulation products are far from being just interim solutions. The Thermal Interface Materials (TIM) from Seifert electronic GmbH ensure optimal thermal connection between heat sinks and the components to be cooled. As electronic assemblies become increasingly compact, even a tiny gap between individual components can disrupt the necessary heat dissipation. Air pockets between the heat sink and the component being cooled hinder the optimal thermal connection. Possible consequences include temperature overload, which can lead to overheating in the worst-case scenario. Thermal management and insulation products act as connectors between the heat sink and the electronic component being cooled. They fill every tiny gap between the heat sink and semiconductor with thermally conductive material. This ensures optimal thermal connection and prevents any heat buildup.

Request for a quoteResults for

Heat sinks for electronics - Import exportNumber of results

7 ProductsCompany type