- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- farm grinding machinery

Results for

Farm grinding machinery - Import export

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A 40-60 TPH Limestone Crushing and Screening Plant is a facility designed to process limestone raw material into high-quality aggregates with a throughput capacity of 40 to 60 tons per hour. These plants are specifically designed to cater to the demands of different industries like construction, road building, and landscaping, where such high-quality limestone aggregates are required. It usually hosts primary crushing equipment, screening machinery, and conveyors—all designed to handle limestone material conveniently. The initial processing of larger limestone rocks into smaller, more workable fragments is done with primary crushers like jaw crushers and cone crushers. This is very important for the sizing of the raw limestone material, required for further processing, into a size that is ready for making the final product, as per the defined size and quality requirements.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 700-1000 TPH dolomite crushing screening plant shall be a high-capacity industrial plant built to crush dolomite ore, which can produce all the required aggregates for construction projects. The term "TPH" means how many tonnes of dolomite ore the plant can get through in an hour, which is between 700 to 1000 tonnes per hour. This capability makes it be a core element in vast construction projects that require dolomite aggregates continuously. Dolomite, being of the composition calcium magnesium carbonate, is an essential material for construction, more so in the manufacture of concrete aggregates, road base materials, and other important building resources. These plants thus ensure that dolomite is well processed and sorted out to suit the specifications of construction applications.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

These plants long lifespan makes them ideal for large-scale mining quarrying and recycling operations where the volume and consistency of the material being processed necessitate a dependable long-term solution with high productivity. Portable crushing plants can be built with specific operational requirements in mind taking into account factors like the type of material to be processed capacity requirements end-product specifications and spatial constraints unique to the site. The plant will be able to manage the expected throughput and material properties with this level of personalization providing a tailored solution that maximizes the profitability and productivity of the operations. Modern technology features like automation and monitoring systems which provide operators with precise control over the crushing process are integrated into operations to further improve their efficiency safety and scalability.

Request for a quote

KOBAMET SPOLKA Z.O.O.

Poland

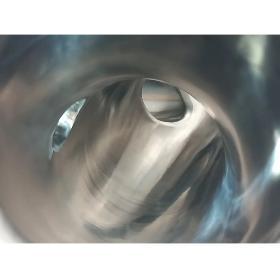

The service of grinding of chromium-nickel (stainless) steel inside and outside is covered: grinding of non-standard elements made of stainless steel /acid resistant/, e.g.: fittings, chutes, collectors, boiler housings, supports, mixers, bottoms, stub pipes, culverts, manholes, reactors for the chemical, dairy, pharmaceutical, food industry, etc..; surface grinding of pipes, elbows, tees, reductions, etc; stainless steel tanks, both external and internal surfaces; grinding of welds, machining of stainless steel components after bending, cutting, machining, etc; grinding of stainless steel sheets (formats); reconditioning of chromium-nickel (stainless) steel, damage removal and repair of various stainless steel components, e.g.: chemical tanks, catering furniture, pharmaceutical equipment, dairy machinery, etc; stainless steel (acid resistant) surfaces by abrasive blasting through stainless steel glazing; roughness measurements Ra and Rz; and others.

Request for a quote

LBI

France

We manufacture rough or fully machined segment liners for grinding mills in 15% leaded bronze

Request for a quote

NETZSCH MASTERMIX

United Kingdom

The nano mill Zeta® RS is the next development of the worldwide known circulation mill system Zeta® type LMZ. Its field of application starts where the other agitator bead mill system Zeta® ends. The highly efficient centrifugal separation system enables the use of smallest grinding media from a diameter of 30 – 300 µm in reliable continuous operation. It is specially designed for wet grinding and dispersing processes especially "gentle dispersing" in the nanometer range. Working with the machines is a pleasure due to its easy operation. The agitator bead mill Zeta® RS is equipped with a swiveling grinding unit and lifting device with multiple positions for easy emptying, filling and cleaning ... ** click to know more **

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Farm grinding machinery - Import exportNumber of results

6 ProductsCountries

Company type