- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electrical equipment and electronics

Results for

Electrical equipment and electronics - Import export

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

As part of our maintenance and repair services, we also perform technical upgrading and modernisation operations on existing electrical equipment.

Request for a quote

ERDWICH ZERKLEINERUNGS-SYSTEME GMBH

Germany

According to initial estimates, in Germany about three million LCD monitors will be recycled in the year 2016. However, they often still have backlighting containing mercury and therefore have to be classified as “hazardous waste” in accordance with the German General Administrative Regulation (AVV) and registered in compliance with the German Electrical and Electronic Equipment Act (Elektro G) under category 3. Whereby special conditions must ensure that no risk arises from the mercury for the environment or for humans. However, because of a lack of suitable automated procedures for the recycling of LCD monitors, it was to date only possible to dissemble the appliances laboriously by hand, with the ensuing health dangers for the workers. For this, ERDWICH now offers two alternatives which are both safe and time-saving for recycling LCD monitors. Mercury and valuable resources can be removed and recycled in an environmentally sound way in the future: 1. Monitor sawing plant for...

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Material: aluminum Strong adaptability Reliable mechanical structure Strong repulsion (adjustable) High efficiency in separation Applications: Electronic waste disposal (refrigerator dismantling lines) Separation of aluminum cans and ferrous metals Separates nonferrous metals from the bottom ash of boiler Separates aluminum or copper block from the sections of abandoned cars Separates nonferrous metals from the glass scrap Separates nonferrous metal impurities in some production lines (such as plastic recycling production line) Separates nonferrous metals from recycled plastic doors and windows metal separator is mainly used to recycle copper, aluminum and other nonferrous metals from industrial waste and solid waste Widely used in Eco-friendly industries, like waste classifications, waste electrical and electronic equipment recycle and the treatment of non-ferrous metal industrial materials High quality, competitive price, best services

Request for a quote

SEACOMP

United States

Contract Manufacturing by SEACOMP Get your concept to physical product with our electronics manufacturing services. Use our engineering team to get your design ready for mass production or let us take your perfectly designed product and build it at scale. We help launch electronic devices for home automation, industrial controls, consumer products, and medical devices. Manufacturing is completed in our wholly-owned China facility that is ISO 13485 certified. Our production capabilities include: - PCB Assembly, Surface Mount (SMT), Through Hole Assembly - Wave Soldering - Reflow Soldering - Plastic Injection Molding (vertical and horizontal) - Ultrasonic Welding - Cable Assembly and Over-Molding We also provide the finished assembly of your product before it is shipped anywhere in the world: - Laser Marking - Pad Printing - UV Ink Curing - Label Printing - UV Light Metering - Box Build Assembly - Bulk or Retail Packaging - Warehousing Contact us to learn more.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Removal of loose oxide and electrode-erosion residues, dust deposits or creepage currents which cause soiling in moving contact areas such as motor-vehicle ignition distributors, relay contacts, resistance or potentiometer slideways, in static contact areas such as motor-vehicle spark plugs, plug-in connections, sliding and screw connections, in or on electrical and electronic equipment or devices of all kinds Advantages and benefits Highly effective due to outstanding cleaning properties Broad range of uses for all maintenance and customer service work in electrical sector Fast evaporation after striking surface

Request for a quote

NORELEM FRANCE

France

Sensitive electrical or electronic equipment, components and devices (ESD sensitive elements) may be damaged or destroyed by electrostatic discharges (ESD) in the immediate vicinity. Electrostatic discharges can come from people or through handling ESD sensitive components (e.g. during production, assembly, transport, storage etc). Electrically conductive products which conform to DIN EN 61340-5-1 are essential within electronic environments to prevent an electrostatic discharge. These products can be used for ESD applications or in ESD protection areas (EPA) in accordance with DIN EN 61340-5-1. Safety: These ESD products can also be used for devices, components and protection systems in areas with high risk of explosion. Use of these ESD products prevents the occurrence of electrostatic spark discharges, eliminating the potential ignition of gases and dusts which could lead to explosions in enclosed spaces.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

OKS 1105 prevents the formation of electrically conductive layers and minimises the risk of flashovers and dielectric losses. The insulators and switchgear covered with the paste thus maintain a good insulation resistance. Sealing lubrication for electrical or electronic equipment such as relays, plug-in connections, cable lugs and lamp sockets Protection of insulators and switchgear in humid atmospheres, for example of junction boxes, screw terminals, overload cutouts at high-voltage pylons, connecting cables and terminal connections Lubricant for plastic screw connections and other moving parts of metal, ceramic, plastic Advantages and benefits Excellent water repellent properties Excellent surface wetting Good adhesion on glass, porcelain and plastics Stable consistency across a wide temperature range Very good resistance to chemical and weather-based influences (e.g. ozone, UV radiation) Neutral with regard to many materials

Request for a quote

ROVIMEX BATTERY AND ENERGY TECHNOLOGIES

Turkey

Economical and easy-to-use desoldering wire. ESD protective product. Dimensions: 1.5mx 1.0 mm Zero Cycle Count, so you have the maximum amount of cycles remaining. Lithium-Ion Polymer technological materials Strict QC test Less than 1% failure rate 12 Yes Garanti

Request for a quote

MFO S.A.

Poland

Mounting rails used for assembly of modular equipment, wires and cables. Bars ideally meet installation requirements and harmonize with the interior. Steel mounting rails are applicable in a wide range of home and industrial installations. Product application: - assembly of electrical modular equipment and other electrical and electronic devices. - lighting assembly

Request for a quote

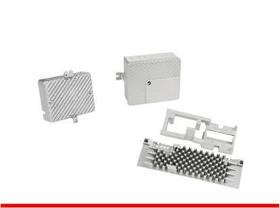

NANOSYSTEC GMBH

Germany

The work area of 700 x 900 mm offers sufficient space. The motion system works with linear motors and linear optical encoders which guarantee extremely high resolution and precision – even at the high speed due to the excellent acceleration of the linear motors. The empty surface of the vertical stage is equipped with an interface for fast tool changing. Sensors measure the force applied by the tools to the device. The desired forces can be programmed so that each device is handled ideally.Eutectic bonding is performed with high energy laser radiation and with a wavelength matched to the device. Temperature sensors transmit the values to the control electronics and the power is precisely adapted. In this way, the temperature follows the desired profile fast and accurately. NanoBond utilizes precision dispensers for gluing processes. These instruments apply a volume from nanoliters to several milliliters. In most application

Request for a quote

NANOSYSTEC GMBH

Germany

Exactly tailored to the respective process requirements of the devices, VersaWeld provides high productivity from the beginning. The application determines which laser source will be used and thus stainless steel, Kovar, Titan alloys and nonferrous metals can be efficiently processed. Typical devices for precision laser welding include sensors, micromotors, medical components and other miniature elements such as housings which require leak tightness.

Request for a quote

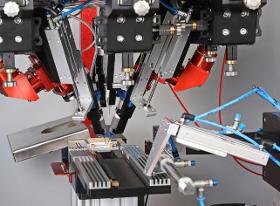

NANOSYSTEC GMBH

Germany

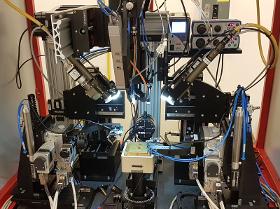

VersaSolder uses selective laser soldering for applications where other methods fail. A laser beam heats an area without impacting the surrounding the key advantage of this non-contact joining technique.A lens assembly focuses the laser power which melts the solder onto the working area. It is tailored exactly to the specific shape of the solder joint and the beam may be circular, elliptic or a straight line. An optional pyrometer measures the temperature in the melt pot and the electronic actively regulates the power profile. Multiple solder heads heat various areas at the same time and a symmetrical arrangement reduces shift. In order to achieve higher productivity, nanosystec developed the Multi Beam Optic (MBO). It generates a number of sub beams processing more than one connection in the same time – up to 40 individual spots have been demonstrated.

Request for a quote

NANOSYSTEC GMBH

Germany

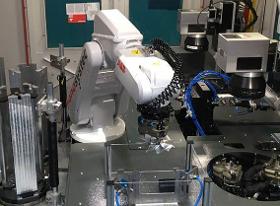

VersaHybrid is a semi or fully automated production system for complex assemblies which require a precision in the low micrometer regime. Assembly techniques include micro welding, selective laser soldering and gluing plus laser fine cutting. Various processing methods are combined in one station. Feeders, belts and robots allow for full automation.

Request for a quote

NANOSYSTEC GMBH

Germany

The fully automated assembly station VersaGlue takes components, such as lenses or dies from a loading area and mounts them by epoxy gluing with UV or thermal curing. The large work area of up to 1000 mm x 1000 mm provides space for the positioning of device trays and support systems. The parts are presented manually or fully automated. Feeders or stop-motion conveyor belts bring the parts to the working area and collect the finished product. The VersaGlue processes optoelectronic elements like VCSELs, photo diodes, laser dies and micro optics with highest precision while the passive placement of fiber ribbon cables is another major application.Thorough design and continuous optimization of all functional groups lead to superior mechanical stability. Mechanical references with tight tolerances provide a repeatable manufacturing operation from device to device.

Request for a quote

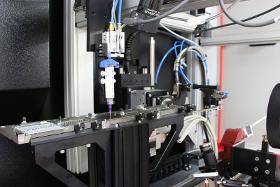

NANOSYSTEC GMBH

Germany

The laser processing station VersaCut precisely ablates and cuts a large variety of materials, such as metals (stainless steel, nonferrous metals), ceramics like Si or AlN, and all kind of plastics. Depending on the indented use, the station uses different laser sources with the corresponding focusing optics. The modular VersaCut finds it application in research and production.A solid-state laser delivering short pulses in the nanosecond regime is ideal for cutting stainless steel, Kovar, brass and similar metals. The high peak power with a small focus on the target generates the necessary power density for clean and sharp cuts. There is however an impact on the surrounding area as some local heating occurs. The high peak power allows also for cutting and ablating plastics, even if the laser wavelength does not match the linear absorption of the plastic.

Request for a quote

NANOSYSTEC GMBH

Germany

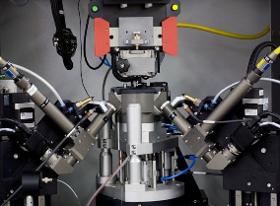

The NanoWeld stations provide the ideal platform for the development and production of opto-electronic components, like singleand multi-channel transmitters and receivers. The station works with exchangeable trays and grippers accepting all device housing types and lenses, optical fibers or receptacles to be aligned and attached. Cycle times for the rapid mass production of TOSA type assemblies reach less than 25 seconds while it takes several minutes for complex devices.All components and subassemblies to build the NanoWeld station are of highest quality and performance. Even customized systems start from a common platform which minimizes development time and cost. By using device-specific trays and grippers, the time to change between different batch processes or device types is reduced to the minimum. Loading and unloading of these trays is performed on a separate loading station outside of the automated NanoWeld. The automated alignment starts from a known reference position.

Request for a quote

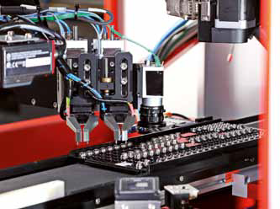

NANOSYSTEC GMBH

Germany

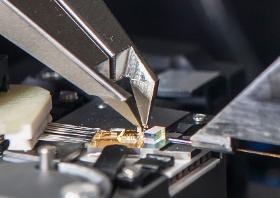

NanoTest VCSEL measures VCSEL on wafer level or Chip on Carrier regarding their optical and electrical characteristics. The tester accommodates wafers with a diameter of up to 6 inches (150 mm), as an option also larger diameters can be integrated. A special interface mounted to the chuck also allows for testing Chip on Carrier devices.A high-precision motion system with XYZ and rotary adjustment brings the wafer chuck in the respective measurement position. First, electrical contacting takes place supported by a sideview camera. A high-precision current source delivers the operating current for the VCSEL under test.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NANOSYSTEC GMBH

Germany

Reliable Opto-Electronic Characterization for DC and RF Values The opto-electronic test station NanoTest PIC HD complies with all requirements for the testing of high-density photonics integrated circuits, such as silicon photonics structures or active PICs. Probe cards with up to several hundreds of contacts provide the connection for DC and RF measurements.

Request for a quote

NANOSYSTEC GMBH

Germany

NanoSolder actively aligns optical components such as photonic circuits, waveguides, diode lasers and photodiodes. It uses selective laser soldering for the assembly. Compared to gluing with subsequent curing, much shorter assembly times will be achieved by selective laser soldering.

Request for a quote

NANOSYSTEC GMBH

Germany

NanoHybrid provides a large degree of versatility. The active alignment, test and assembly station combines various assembly methods including gluing, laser welding or selective laser soldering. In addition, the station offers opto-electronic testing capability. Therefore, NanoHybrid is ideally suited for the development and small serial production in manufacturing companies or in research institutes. In such a product development area, an active alignment station needs to cope with opto-electronic and other precision devices with varying sizes and characteristics.

Request for a quote

NANOSYSTEC GMBH

Germany

NanoGlue serves as the ideal assembly station for opto-electronic components, such as photonics circuits,waveguides, diode lasers and photodiodes as well as lenses and modulators. It provides active alignment in all six degrees of freedom followed by epoxy gluing with UV curing.

Request for a quote

NANOSYSTEC GMBH

Germany

The fine balancing system NanoBalancer corrects smallest imbalances of rotating work pieces with laser ablation. The removal of material is performed either statically after the measurement or dynamically during the rotation of the work piece. Typical examples are impellers for technical or medical applications, airdriven turbines or small rotors of miniature motors.

Request for a quoteResults for

Electrical equipment and electronics - Import exportNumber of results

49 ProductsCountries

Company type

Category

- Import-export - electrical and electronic equipment (26)

- Electric and electronic components - machines for manufacturing (4)

- Passive electronic components and printed circuits (3)

- Electrical & Electronic Components (2)

- Accumulators and batteries (2)

- ELECTRIC EQUIPMENT (2)

- ELECTRICAL SYSTEMS (2)

- Electrical systems and equipment (2)

- Electron beam welding - equipment (2)

- Silicones (2)

- Anti-corrosion products, chemical (1)

- Control boxes - electric (1)

- Electric transformers, converters and rectifiers (1)

- Engine testing and regulating equipment - electronic (1)

- Handles - doors, wooden (1)

- Metal slotting machines (1)

- Motor mechanics - hand tools, non power (1)

- Weight and mass - measurement and regulation instruments (1)

- Welding, electric - equipment and supplies (1)