- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- band saws

Results for

Band saws - Import export

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

Standard equipmentwith tilting alu sliding table 1000x800 mm Cutting height 424 mm Cutting length 700 mm Roller diameter 500 mm Saw band length 3720 mm a) for three-phase current 400 V, 50 Hz, motor power 1,3 KW b) or alternating 230 V, 50 Hz, motor power 1,3 KW only saw band, to be selected according to the type of stone material with jack rings and 2 rollers Sound emission Lpa according to DIN 45635, part 1651 on gas concrete and lightweight refractory bricks ...75 dB(A) on Poroton ...................................... 88 dB(A) Size LxWxH: 1000x1000x1800 mm Weight: 130 kg

Request for a quote

ADAÇAM MACHINE AND BAND SAW FACTORY

Turkey

A BAND SAW MADE FROM A HIGH QUALITY OF GERMANIAN STEEL C75 S

ADAÇAM MACHINE AND BAND SAW FACTORY

Turkey

A BAND SAW COVERED BY STELLIT WHICH PROVIDES EXCELLENT SURFACE OPTIMUM REGULARITY AND CONTROLLING CUTTING

PILANA METAL S.R.O.

Czech Rep.

Bimetal band saw blade with extra wear resistance Application: cutting steels with tensile strength up to 1700 MPa high alloy steel and stainless steel titanium alloys and nickel hard machined materials Characteristics.

Request for a quote

DISPA MACHINE

Turkey

• Semi-automatic double miter for cutting profiles and solid material in steel and non-ferrous material and an excellent price-performance ratio • Manually swiveling saw frame with hydraulic clamping for optimal • Hydraulic clamping of the horizontal vise • Automatic saw frame raising on the cut end • Double speed motor 1.0/1.3 KW Gearbox • Sensitive cutting pressure regulation function of the material properties • Hydraulic-mechanical belt tension • Tape guide with hard metal pads sheets and rolls • Thermal overload protection and no-volt release • Automatic shut-off after cut end • Automatic belt break protection Driven

Request for a quote

DISPA MACHINE

Turkey

Double Column Bandsaws with linear guideways are ideal for MITRE cuts with different quantities. With the movement of the bow, it’s possible to cut between 90° and +45°. With height adjustment and hydraulic cutting, control allows the bow to go up over the material after the cut. All this process is controlled by a digital counter on the control panel and total duration for one cut decreases. Fixing the bow at any angle is controlled by the hydraulic brake system.

Request for a quote

SPANSET SECUTEX GMBH

Germany

The secutex material may be sawn using a conventional band saw. The material will attempt to resist the cutting tool. Use as low a wedge angle as possible and, if necessary, adjust the cutting speed.

Request for a quote

SPANSET SECUTEX GMBH

Germany

Install impact protection For screwing and riveting secutex impact protection with an internal perforated plate can be screwed or riveted in different ways. You can achieve universal impact protection in no time at all. For welding Welding is often the easiest and fastest way of fastening. The various protruding perforated sheet designs allow a very versatile use. For gluing If screwing or welding is not possible, the impact protection can be glued with the secutex special adhesive. Cutting and sawing The secutex material can be sawed with a conventional band saw. The material tries to avoid the cutting tool. Make sure that the wedge angle is as small as possible and adjust the cutting speed if necessary. Milling Use commercially available milling cutters with a small number of teeth. Circumferential speed approx. 200400 m / min, clearance angle ∂ 10 °, clamping angle y 25 °. The use of a drilling emulsion is recommended for cooling and surface optimization. Rotate

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

An efficiently sharpened saw blade is essential for productive and safe work processes. Tyrolit offers an extensive range of grinding tools for various saw blades, including chain saws, circular saws, band saws, and gang saws. Our abrasives are precisely matched to different grinding machines and tooth pitches for optimal sharpening results, featuring vitrified-bonded grinding wheels and resin-bonded diamond and CBN wheels for special applications. Tyrolit’s decades of experience are evident in our tools' grit qualities and innovative bond systems, ensuring optimal cutting edge quality. Our grinding tools for automatic chain saw sharpening machines promise extended service life and perfect tooth base radius matching. We also offer resin-bonded diamond wheels for special applications and CBN tools for grinding HSS and high-alloyed steels.

Request for a quote

NOVELTY STEEL

Turkey

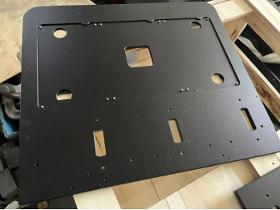

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK

Germany

SCHMIDT Zerspanungstechnik's contract manufacturing department has a well-provisioned materials warehouse and the latest automatic band saws SCHMIDT Zerspanungstechnik's contract manufacturing division is a competent partner when it comes to cutting by saw too. We stock standard materials in the most common dimensions in our materials warehouse for you. This means that we can respond to requests extremely quickly. We have two ultramodern automatic band saws that can precisely cut to size materials with a diameter of up to 450 mm. The machines are capable of cutting mitres and stack cutting too.

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK GMBH

Germany

SCHMIDT Zerspanungstechnik's contract manufacturing department has a well-provisioned materials warehouse and the latest automatic band saws SCHMIDT Zerspanungstechnik's contract manufacturing division is a competent partner when it comes to cutting by saw too. We stock standard materials in the most common dimensions in our materials warehouse for you. This means that we can respond to requests extremely quickly. We have two ultramodern automatic band saws that can precisely cut to size materials with a diameter of up to 450 mm. The machines are capable of cutting mitres and stack cutting too.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

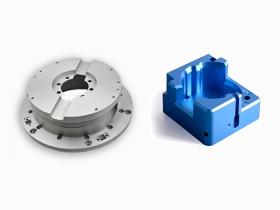

Ming Xiao Mfg custom CNC machined parts by CNC Turning & Milling for worldwide customers. Precision Machining: Our facility is equipped with a wide range of CNC machines including CNC lathes, turning centers with live tools, horizontal and vertical band saws, etc. This helps us to produce precision machined CNC parts. CNC Milling and Turning: We have equipment with 3, 2, 3+2, and 5 machinery axis, which helps us provide end-to-end CNC milling and turning services. Additionally, we can offer sub-operations, such as knurling, milling, drilling, etc. Our Capabilites Maximum Diameter: 600mm Maximun Length: 1200mm Highest Tolerance: ±0.01 (Depending on the parts’ size) ISO 2768 f Available Surface Roughness: Ra 0.4 / Rz3.2 / ▽8 If you are interest in our CNC turning and machining services to produce your aluminum machined parts, welcome send your drawing or samples with detailed requirements to us, we shall reply you in 48 hours and work a more competitive price for you.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg custom CNC machined parts by CNC Turning & Milling for worldwide customers. Precision Machining: Our facility is equipped with a wide range of CNC machines including CNC lathes, turning centers with live tools, horizontal and vertical band saws, etc. This helps us to produce precision machined CNC parts. CNC Milling and Turning: We have equipment with 3, 2, 3+2, and 5 machinery axis, which helps us provide end-to-end CNC milling and turning services. Additionally, we can offer sub-operations, such as knurling, milling, drilling, etc. Our Capabilites Maximum Diameter: 600mm Maximun Length: 1200mm Highest Tolerance: ±0.01 (Depending on the parts’ size) ISO 2768 f Available Surface Roughness: Ra 0.4 / Rz3.2 / ▽8 If you are interest in our CNC turning and machining services to produce your aluminum machined parts, welcome send your drawing or samples with detailed requirements to us, we shall reply you in 48 hours and work a more competitive price for you.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Napkin production is a process that requires precision and quality and an important part of this process is Band Saw Napkin and oll Cutting Machine. This machine increases efficiency and quality in napkin production by making high speed and sharp cuts. Band Saw Napkin Cutting Machine is one of the last stages of the product before reaching the end user, especially by ensuring that the napkins are cut in standard sizes and with smooth edges. Band Saw Napkin Cutting Machine is an industrial machine used to cut large napkin rolls in specified sizes. Using band saw technology, it cuts napkins at high speed and smoothly. This machine is suitable for both plain and patterned napkins and offers high cutting precision. High Cutting Speed and Precision: It performs the cutting process quickly and precisely. Flexible Production Capability: Ability to cut napkins of different sizes and patterns. Durable Structure: It has a robust structure suitable for continuous and intensive use.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The new HBE Performance Series offers high performance, with ease of use and efficiency. An increase in performance while reducing power consumption, combined with a small footprint, increased health and safety aspects and still provide easy handling were just some of the demands within its development. The HBE Performance series brings many features, which make your production even more profitable: — A solid and durable design made of vibration dampening grey cast iron — Outstanding cutting performance by Servo-Downfeed system with Auto-Feed-Control — Excellent blade life due to the sensitive BEHRINGER downfeed control system, inclined band wheels and effective chip disposal — Easy operation by intuitive NC control system Different models based on cutting range ( 90° flat / 90° round): — HBE560A Performance: 560 x 560 mm / 560 mm — HBE663A Performance: 710 x 660 mm / 660 mm — HBE860A Performance: 860 x 860 mm / 860 mm — HBE1060A Performance: 1.060 x 1.060 mm / 1.060 mm

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The automatic plate saw VPS60-160A is BEHRINGER's solution when it comes to fully automatic cross-cutting of large plates and blocks. The vertical arrangement of the saw band has clear advantages over the horizontal design, as the engagement length of the saw band is significantly shorter. As a result, the cross cutting plate saw offers significantly higher cutting capacities while at the same time reducing tool costs. Thanks to their robust basic design and high-performance components, the automatic plate saws of the VPS series are designed for demanding applications in the steel trade, industry and metal production. From non-ferrous metals and aluminum to simple work steels and difficult-to-cut materials such as Inconel or titanium. Their modular design allows the cross cutting plate saw to be individually adapted to the customer's application.

Request for a quote

HIRSCH KOVIFLEX D.O.O.

Slovenia

Cutting profiles up to 350x300mm with the option of angled cuts. Our advantage lies in having a wide range of raw materials in stock, enabling us to offer short lead times. Competitive edge includes rapid responsiveness and adaptability to changes.

Request for a quote

PROSAW LIMITED

United Kingdom

Heavy Duty Automatic Bandsaw for solid bar, bundles & general sawing with the following features: Vice feed automatic with encoder for precision length set Twin hydraulic vices clamp both sides of material Simple input of component length and number of pieces via touch screen Steplessly variable blade speed 17 ~ 67m/mm Hydraulic blade tension control for optimum blade life. Variable downfeed control. The touch sensitive control screen provides easy selection of precise bar length requirement for a precise cut off length. The auto head-elevation reduces index cycling time significantly. The Blade speed is set and adjusted by acting on the touch sensitive control screen. There are quick-adjusting carbide saw-band guides, there is an idle wheel motion protector, a hydraulic band tension control, a quick-action HYDRAULIC twin-vice (split vice) 3-jaw clamping, a unique two-way vice jaw and an automatic chip conveyor.

Request for a quote

MERCEL, CUTTING KNIVES S.R.O.

Czech Rep.

Our company supplies knives both for the own processing of food, but also for the entire food industry. In addition to the food division itself, knives in the food industry are used, for example, in packaging processing in packaging lines. We also supply food knives in stainless steel. Our product range includes: cutter knives deburring knives filling needles knives for meat mills cutter knives knives for packaging machines band saws

Request for a quote

WINTERHOFF PICARD GMBH

Germany

When brought into contact with foods, some of the requirements optimally fulfilled by our knives include the minimization of cutting waste, no sticking of the foods, perfect cutting surfaces, insensitivity to acids, no risks to hygiene and cleaning.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

We are not dictated to by standards. If at all, our sole and uncompromising standard is to produce the best possible knife for your task. We are your experts in this.

Request for a quote

KSL

Ukraine

KSL provides quality locksmith work Locksmithing is a metalworking process that usually complements other types of metalworking and brings the product to a finished state. Locksmith work is performed with the help of a special manual or mechanized locksmith tool or on various machines. Locksmith work at KSL is performed by qualified specialists who approach their work responsibly and achieve flawless results of accuracy. We can guarantee that the locksmith processing of parts at KSL will be performed in exact accordance with your requirements and in the shortest possible time. The main types of locksmith work used by KSL: Countersinking and thread cutting of various diameters; Drilling of various diameters; Band sawing works; Cleaning of seams after welding; Metal polishing. You can familiarize yourself with us in more detail: Website: ksl-pro.com or ksl.ua Mail: zakaz@ksl.ua Phone: +38 (050) 011 83 29 #locksmithworks #drilling #lpolishing #metalbending #milling

Request for a quote

ARNTZ GMBH + CO. KG

Germany

The universal band saw blade for all construction and insulation materials of small and large dimensions running on brick band saw machines. The new variable tooth pitch ensures notably low-vibration and quiet sawing processes and assures supreme quietness. The results are clean and smooth cuts of the best quality. Thanks to its long blade life and increased durability, our further developed, precision-ground tooth geometry is particularly convincing in hard building materials: • particularly low vibration and quiet • long blade life in especially precise and smooth cuts The specialist for: • Pore or lightweight concrete • Perforated brick • Porous bricks ("Poroton") • Insulation material

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Stainless steel • Heat resistant steels • Cold and hot working steels • Hardened steel up to 1900 N/mm2 • Nickel based alloys • Aluminium-silicon alloys • Copper-nickel alloys • Titanium and titanium alloys • Exotic, hard to cut alloys

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Induction hardened piston rods • Steels hardened up to 62 HRC • Hard chromium plated materials • Manganiferrous alloyed steels

Request for a quote

ARNTZ GMBH + CO. KG

Germany

Engineered for : • Aluminium alloys • Aluminium bronzes • Copper alloys • Sand cast aluminium and cast magnesium • Graphite

Request for a quoteResults for

Band saws - Import exportNumber of results

53 ProductsCountries

Company type

Category

- Hand tools, non-power (18)

- Blades for saws and cutting machines (10)

- Sawing machine tools (4)

- Milling - steels and metals (3)

- Cutting - steels and metals (2)

- Industrial sheet metal work (2)

- Knives, industrial (2)

- Sawmills - machinery and equipment (2)

- Blades and knives, industrial (1)

- Electrical engineering hand tools, non-power (1)

- Filtering equipment and supplies (1)

- Grinding - machine tools (1)

- Machine tools, metal machining - parts and accessories (1)

- Metal structural work (1)

- Milling - machine tools (1)

- Paper - manufacturing machinery (1)

- Raw materials for construction and public works (1)

- Sheet metal and strips, tinplate (1)

- Steel sheets and strips (1)

- Steel, structural (1)