- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- magnetic dirt separator

Results for

Magnetic dirt separator - Import export

VIRA ISI

Turkey

Magnetic Deaerator and Dirt Separator are used with a single device to dissolve microbubbles, dirt, and air in high performance in heating and cooling installations. Micro smart filter design is the most important element of the system design. Optimum air and microbubble separation and very low flow resistance are available. It also has a high degree of dirt handling. With its magnetic Separator feature, ViraPlus separates the moving metal particles in the installation more effectively and ensures faster cleaning of the installation. It also extends the life of your pump and other connecting equipment by minimizing the damage caused by metal parts to high-efficiency pumps that provide low energy consumption.

Request for a quote

F.E.S. GMBH

Germany

Chain Magnetic Separator are used for the cleaning of liquids contaminated with magnetizable solid particles and foreign oils. F.E.S. separator systems can be used in full-flow or bypass cleaning applications. The separation performance varies depending on the level of contamination and the volume flow rate. Note: The separator systems can be supplied via a separate supply pump, existing system pumps (with sufficient reserve capacity within the existing system components), or a free inlet (with sufficient geodetic height difference). Advantages: No filter aids required High separation efficiency Large throughput capacity Large active separation surface due to favorable separation geometry and optimal arrangement of magnets Low wear and tear Operating Principle: The contaminated liquid is supplied to the separator through the flange (1) located at the bottom.

Request for a quote

VIRA ISI

Turkey

In heating and air conditioning control systems, the circulation of water containing impurities may result in rapid wear and damage to components such as pumps and control valves. It also causes blockages in the heat exchangers, heating elements, and pipes, resulting in a lower thermal efficiency within the system. The dirt separator separates off these dirt particles, collecting them in a large collection chamber, from which they can be removed even while the system is in operation. This device is capable of efficiently removing even the smallest particles, with extremely limited head loss.

Request for a quote

GOUDSMIT MAGNETICS

Netherlands

Magnetic separators filter ferrous and weakly magnetic metals from your product flow. These contaminants can remain in your end product and cause rejection, but can also damage your process machines. Examples of ferrous metals in your production line: rivets, nails and screws of packaging, loosened bolts and nuts, wear of moving parts, rust or corrosion. We offer you a wide range of magnetic separation systems, that are suitable for removing large loosened parts, up to very fine wear particles. And with manually to fully automatic cleaning systems.

Request for a quote

GOUDSMIT MAGNETICS

Netherlands

Magnetic separators filter ferrous and paramagnetic metals from product flows. These contaminations can remain in your end product and cause rejection, but can also damage your process machines. Examples of ferrous contamination in your production line: rivets, nails and screws of packaging, loosened bolts and nuts, wear of moving parts, rust or corrosion. We offer you a wide range of magnetic separation systems, that are suitable for removing large loosened parts, up to very fine wear particles. And with manually to fully automatic cleaning systems.

Request for a quote

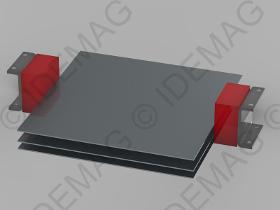

IDEMAG

Spain

The magnetic sheet floaters are designed for separation of magnetic steel sheets, clean , oily or sticky sheets. They help boost press and press brake production by eliminating the need to fumble with thin oily sheets. It also operates in automated systems. For a good selection of magnetic floater in the separation of plates, first of all we should know the thickness of the sheets, since it is a critical input to do a good job. One thing to bear in mind is that the magnetic float IDG.FS.RB shall be 90 mm higher than the stack of sheets to be separated. Construction features: * Stainless steel case. * Construction of the magnetic circuit with powerful permanent magnet, which can not be demagnetized. * High resistance welded box. * Threaded holes in the mounting base for a quick assembly * Ceramic or Rare Earths magnets. * Non-standard size. * Sizes and configurations according to customer characteristics. * Available in various magnetic forces.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Magnetic dirt separator - Import exportNumber of results

6 ProductsCountries

Company type