- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- process monitoring

Results for

Process monitoring - Import export

FESSMANN GMBH UND CO KG

Germany

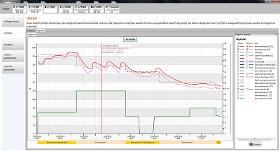

The software for process monitoring from FESSMANN is the simple answer to complex production processes with its operatorfriendly, Windowsbased control. FOOD.LOG provides an overview of all data required for quality assurance of your products. The ergonomic, intuitive user guidance and storage of all data in a database make it simple for FOOD.LOG users to monitor multiple systems at once. Choose between FOOD.LOG basic, professional and enterprise in order to meet your individual demands to production monitoring. FOOD.LOG will make sure that you miss nothing. All system and operating conditions can be documented precisely. Processrelevant data such as chamber and core temperatures, Fvalue, process duration or relative humidity are recorded by the program and saved. FOOD.LOG permits precise production control and evidence, also according to DIN ISO 9000. You can comfortably create and edit goods programs from anywhere.

Request for a quote

MICRO-HYBRID ELECTRONIC GMBH

Germany

Two channel premium pyrodetector detector on TO39 header for measurement of sulfur hexafluoride (SF6). The detector suits applications of industrial gas measurement or monitoring of insulation gases in the field of production and process engineering at ambient temperatures between -20 and 85 °C. With a CWL of 10540 ± 100 nm and a HBW of 690 ± 100 nm, the narrowband optical filter provides ideal values for precise analysis of the target gas. In addition, there comes a reference channel with the CWL: 5060 ± 25 as well as the HBW: 100 ± 15 nm. With a very high detectivity of up to 4.0*10^8 cm√Hz/W and sensitivity of up to 200000 V/W, the signal quality remains unique in this technology range. The detector features a broad spectral sensitivity 2 - 15 µm (optimized from 3 - 5 µm), a high sensitivity with a modulation frequency of up to 100 Hz, a low microphone effect due to the small membrane mass, very low temperature dependence and an amplified signal in current mode.

Request for a quote

MICRO-HYBRID ELECTRONIC GMBH

Germany

The MPS2SENS sulfur dioxide is matched by its filter windows to analyze sulfur dioxide (SO2) with a CWL of 7300 ± 50 nm and a HBW of 180 ± 20 nm (reference channel with CWL: 5060 ± 25 and HBW: 100 ± 15 nm). The detector stands out due to its high detectivity of up to 4.0*10^8 cm√Hz/W and a high sensitivity of up to 200000 V/W. The pyroelectric sensor features 2 chips with a thin film CPM membrane in the core. (CPM: Ceramic Pyroelectrical Material). Further important product properties for long-term use in demanding applications: wide spectral sensitivity 2 - 15 µm (optimized from 3 - 5 µm), high sensitivity with a modulation frequency of up to 100 Hz, low microphone effect due to the low membrane mass, very low temperature dependence, amplified signal in current mode. The MPS2SENS sulfur dioxide provides reliable readings in environments between -20 and 85 °C for NDIR gas measurement in aerospace, industry and environmental technology.

Request for a quote

ELTEX-ELEKTROSTATIK-GMBH

Germany

During printing and coating processes, so-called ink mist or particle mist arise in the outlet of doubleroll systems. This unwanted particle deposit results in lower product quality, high maintenance costs, increased ink consumption and the contamination of the environment. The formation of ink mist is very noticeable and annoying, particularly during coating and printing processes on substrates with non-absorbent surfaces (films, metalized substrates or composite films). A patented double-row DC plasma electrode is used to prevent this ink mist. This plasma electrode acts separately on both particle streams and ensures an optimal particle deposit. The electrode will be connected to the high voltage generator HSG61. The MISTING TACKER system is currently used for printing on metalized films and in silicone coating units (Wifag-Polytype).

Request for a quote

SHS PLUS GMBH

Germany

The plusMETER combines the functionality of a power monitoring system, a process data acquisition system as well as that of a process control system in a single device and can replace whole control cabinets because of its integrated load circuit. Acquisition of all energy carriers Don’t limit yourself to electrical energy – all energy flows in your facility can be acquired and plotted by one central device. Transparent production costs Keep an eye on your profit margin – automatically visualize production costs or communicate them to your ERP system. Remote maintenance Avoid engine downtimes by worldwide system access for problem analysis – for authorized personnel only, of course. Communication of events Stay up to date, define events and keep being informed automatically either by e-mail or directly per push message on your smartphone. Automatization of routine tasks Automate maintenance processes and more..

Request for a quote

QUELLTECH GMBH

Germany

Initial Situation: Inspection of a laser weld seam for pores and geometrical anomalies The production of a client in automotive industry is subjected to extremely stringent quality requirements. This is valid particularly also for the precision of laser weld seam of fine mechanical work. 100% inline supervision is required for the following task: A laser weld beam (width ca. 200µm) has to be verified with respect to the presence of pores and geometrical anomalies. Camera inspection performed until now turned out to be not stable. Therefore the client is forced to implement an improved monitoring process. The challenge The resolution required amounts to 4µm. The high gloss finished material and glossy laser weld seam may give rise to reflections, and the space for installation is restricted. A low form factor for the monitoring equipment is imperative.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Pressure on price and quality continue to rise. The need to monitor even the simplest manufacturing and assembly process is increasingly common. With 100% monitoring of force/ time curves or force displacement/time curves, the Force- Master satisfies all requirements for ensuring the reliability of even simple press-fit processes. Thanks to its ultra-simple, single-button operation and intelligent auto-configuration, even semi-skilled staff can set up the equipment safely and quickly. "Card & Go" is the smart system that uses master, tool and PLC smart cards to make equipment settings, inhibit unauthorized changes and to trigger actions in sequence with the production process. The ForceMaster 9110 has been developed specifically for monitoring manual lever presses. Simple manual workstations can be monitored extremely efficiently using the ForceMaster. Easy control functions that used to require an additional PLC can now be performed reliably with the ForceMaster.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The preeflow flowplus16 is a material-resistant, dead space-free miniature pressure sensor in the smallest design - for moving fluids. The "Luer-Lock" (male/female) on both sides makes it suitable for all common dosing systems that work with this type of thread. The sensor generates a standardized, compatible, linearized and temperature-compensated output signal. Existing dosing systems can be easily extended and protected with the pressure sensor. The flowscreen is a robust evaluation device for applications in various fields of application. In combination with the pressure sensor flowplus16, a complete system for fluid process monitoring is created. Thanks to standardized signals and standardized connections, the components can also be integrated as individual components. Your advantages: - Inline sensor - A pure flow sensor - Maintenance-free - Supply/voltage supply 24 V +- 10% - Mechanical Luerlock connection to DIN EN 1707

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

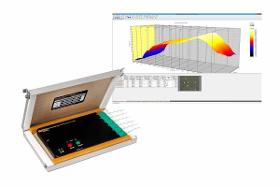

The DIGIFORCE® 9307 monitors processes in which precisely defined functional relationships between two or more measured quantities need to be demonstrated. These measured quantities are recorded synchronously during the manufacturing process or subsequent functional testing to produce a measurement curve, which is then assessed using graphical and mathematical evaluation techniques. After internal evaluation, the measurement curve and computed evaluation results are visualized on the color display and are also output at the external control interfaces. The processes in the controller are optimized by a powerful real-time operating system to achieve an extremely fast evaluation cycle: it typically takes just 15 ms to deliver the global OK or NOK evaluation result, which can then be analyzed by the higher-level controller.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

By using an array of sophisticated sound sensors, the SV600 can be mounted close to any equipment or asset, to any area of the production line, or where human access is restricted or dangerous to ensure you can monitor the most important parts of your facility without interruption. As a fixed, automated solution, the SV600 integrates with your process and eliminates the need for lengthy fault-finding processes such as soapy water tests, when used as part of your product leak testing process. By continuously monitoring your environment, you can quickly detect and fix air leaks – reducing your consumption of compressed air and energy to help save your facility money. Key Features: High-end 24/7 acoustic monitoring 64-Digital MEMS microphones placed in a Sunflower Array Integrated visual light camera Powerful processor for onboard real time processing Sound classification Frequency filtering dB values and sound intensity mapping Event triggering

Request for a quote

KELLER PRESSURE

Switzerland

The series 13 pressure transducers have internal water cooling and are suitable for use in media temperatures of up to 350 °C. Typical applications include superheated steam circuits, engine test benches or chemical process monitoring.

Request for a quote

INFICON GMBH

Germany

FAST, FIELD-READY PROCESS MONITORING SYSTEM Performance, Reliability, and Versatility INFICON Transpector CPM has been the market-leading Residual Gas Analyzer (RGA) process monitoring system in the semiconductor industry for over a decade. Now Transpector CPM 3 provides industry leading measurement speed and sensitivity through a field proven pumping and inlet system integrated with a new sensor and electronics. Transpector CPM 3 is the ideal RGA process monitor for new and established semiconductor processes such as ALD, CVD, PVD, and Etch. Transpector CPM 3 provides proven return on investment to our partners through: 1 Ion source pressure reading @ low emission using total pressure lens 2 Total pressure accuracy @ low emission 3 Maximum ion source operating pressure @ low emission 4 2x10 -4 Torr in the ion source will produce about 1x10 -5 Torr in the quadrupole region 5 MDPP at the ion source with EM on and 1s dwell time 6 Mass 40 contribution onto 41 AMU 7 Zero blast...

Request for a quote

ENVEA

France

Eco-designed, ultra-compact, smart & connected continuous gas analyzer, for emission or process gas monitoring. Perfectly suited to control SO2 removal efficiency in processes using Flue-gas desulfurization FGD / DeSOx systems.

Request for a quote

INFICON GMBH

Germany

Powerful Yet Compact Solutions for Deployment of FabGuard FabGuard Controllers provide powerful compact solutions for deploying FabGuard integrated process monitoring solutions. These reliable industrial controllers connect with tools and sensors through FabGuard to perform real-time data acquisition and analysis, whether for detailed chamber-specific analysis or as part of a fabwide SPC & FDC system. FabGuard Controllers support INFICON sensors, third-party sensors as well as the variety of tools found throughout fabs. Even the demanding requirements of high-speed applications can be met using the FabGuard High Speed Controller.

Request for a quote

BOURDON HAENNI GMBH

Germany

Bourdon takes mechanical pressure monitoring into the digital age This innovative device fits to any comprehensive platform for machine and process monitoring as well as the preventive maintenance of equipment which is supported by a LoRa wireless protocol. Key applications include pressure measurement and monitoring for oil refineries, petrochemical industry and biodiesel plants. More predestined applications are in waste and water treatment, power generation and transmission, general process industry, building services and civil engineering. The right choice when industry grade wireless pressure measurement and monitoring is required

Request for a quote

CIC - KLAUS CZERWONKA

Germany

CIC will be happy to support you in planning, securing, controlling, monitoring and optimizing your quality management, e.g. with: advanced quality planning supplier quality purchased part quality component qualification product engineering Supplier Audit Internal audits Process monitoring and process optimization Production control and monitoring at the supplier bottleneck coordination production readiness tool design Tool tracking mold trials Gauge concepts and gauge acceptance component measurements Resident Engineering Task Force Abbreviations such as APQP, PEP, FMEA, PPAP, 8-D, 5Why are not foreign words for us but common tools.

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

Monitor the quality in your extrusion line, fiber production, polymer production or food and chemical production continuously in real time with the Promix Visco-P inline viscosity meter. Prevent scrap production and reduce raw material costs through active raw material management. Promix Visco-P is a true online rheometer that helps you monitor your production process and save production costs. Ask for a test unit and see for yourself! Advantages Promix Visco-P inline viscosity measurement ,Continuous monitoring of raw material quality and process conditions in real time ,Raw material cost reduction through active raw material management ,Precise inline viscosity measurement in the melt stream – without bypass ,Suitable for all viscous media ,Additional benefit of melt and temperature homogenization in the Promix melt blender, which also serves as a measuring section ,Can be integrated into any extrusion line ,Test units available

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

2-component dosing solution with optimum installation space design cascadable multiple dosing system with small dosing head distances minimum space requirement in automation systems. The ViscoDuo-P 4/4 2-component dispenser is a valveless, static, space-saving mixing head with dispensers arranged directly in front of the mixer. The EC version dispensers have been specially designed for easy cleaning (Easy-Clean) and checking of the pump interior. No valves are required in the mixing head. The components to be mixed are metered into the static mixing tube purely volumetrically via the dispenser without dead space. Your advantages: - Processing of viscous materials, unfilled as well as very highly filled supply of the medium with only low inlet pressure - Setting the desired mixing ratio by adjusting the speed ratio of the two dispensers - sensors integrated without dead space in each component for online process monitoring - Withdrawal possible

Request for a quote

INFICON GMBH

Germany

THE STANDARD IN GAS ANALYSIS Excellent Performance and Great Value for General Vacuum Applications As manufacturing technologies advance and quality standards change, the need to understand your process and maintain product quality is more important than ever. Transpector MPS can help you optimize your process by monitoring process conditions, detecting contaminants, and checking for leaks. Transpector MPS offers the robust performance of the Transpector brand of RGA at an excellent value for our customers. Transpector MPS is available in both 100 amu and 200 amu versions, which gives you the flexibility of performing a wide variety of functions including general leak detection, vacuum diagnostics, and hydrocarbon analysis. This versatility makes Transpector MPS the sensor of choice for vacuum furnace, heat treating, and vacuum coating applications. (1) at 10% of peak height (2) during an eight hour period, after a half hour warm up; in FC mode only (3) 256 millisecond dwell time

Request for a quote

ZEMO VERTRIEBS GMBH

Germany

Error Proofing Takes a Giant Leap Forward The Exacta Series of Radio Equipped Digital Torque Wrenches is the final piece in connecting all the torque application and data about every hand tool tightened fastener in your assembly. We have different Exacta digital wrenches to work with the Global Series of Process Monitors/Controllers. Learn more about how these nearly indestructible yet sophisticated torque application measuring tools can add value to your assemblies. The 1200 Series Exacta 2 Digital Torque Wrench has earned the reputation of being the hardest working, most accurate, reliable and durable digital wrench on the market. That reputation is built on much more than the ± 1% Indicated Value accuracy. The 1200 Series Exacta 2 pairs with the Global 400 and Global 400mp only. It does not communicate or pair with the Global 8. Note: The 1200 Series Exacta 2 Digital Torque Wrench is engineered to work with the radio in function mode. It will not perform without the radio...

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Through a representative office in Hong Kong, CIC supports the often difficult procurement of technical products from China, e.g.: efficient search for suitable suppliers direct, native speaker contact with the producer Contract design and processing Supplier Qualification Quality monitoring Logistics control ZURÜCK

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoDuo-VM 2-component dispenser is a valveless dosing system for static mixing based on the proven progressive cavity technology and thanks to its purely volumetric precise dosing principle, is ideally suited for high-precision dosing tasks. Built according to modular structure, a configuration of the 2-component dosing systems as well as maintenance and part exchange at module level is possible. The material components are mixed downstream of the mixing head only in the mixing tube to prevent material hardening in the system components of the mixing head. Your advantages: - repeatable dosing volume even with viscosity and density fluctuations - Processing of low to high viscosity materials with low to very high filler content - Dispenser and mixing head segments can be combined in size due to modularity - standard equipment with dead space-free integrated dosing pressure sensors for online process monitoring - simple assembly/disassembly of the components

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

DIGIFORCE® 9311 is the new standard in efficient quality control. The pioneering force/displacement controller delivers rapid, precise evaluation results for applications that demand both high quality and high productivity. The smart performance features and intelligent hardware make test equipment quicker to set up, easier to use and capable of automatic integration in modern production systems. This unrivalled product specification gives businesses the added security and dependability they need for increasingly complex production processes. The DIGIFORCE® 9311 monitors processes in which precisely defined functional relationships need to be demonstrated between two measured quantities of the process. For instance when recording and monitoring processes such as press-insertion, joining, riveting, stamping or caulking, reliable quality control depends on synchronous and high-speed acquisition of measured values combined with analysis based on versatile evaluation elements.

Request for a quote

CRYOSNOW GMBH

Germany

• Control cabinet with process control, inspection and monitoring for automated applications • Integrated control and safety components • Simple, ergonomic operation • For use with stationary CO2 tank (or bundles) • Modular construction, design according to customer requirements

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This high performance computer-controlled machine is the optimal solution for mid-sized batch demands at fast throughput times! The E 40 is, like any of our machines, designed for high performance at low consumption of nitrogen, blasting media and electric energy. The comfortable operator features on newest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network connection (support via internet), recipes memory, user management, logging/documentation/traceability and optional barcode scanner/ID key. For industry 4.0 demands, the E40 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control OPC-UA server is possible, too. Furthermore, this machine is able to perform cryogenic deburring without need of blasting media (drum only deflashing), suitable for special applications only. mid-sized batches > fast throughput times > E40

Request for a quote

MESUTRONIC GMBH

Germany

metal separator was developed for the examination of plastic granulates, ground material and powders for metallic foreign bodies. It is used in the injection molding and extrusion areas for slow-flowing material columns. Both the detector and the ejection unit have been specially developed for this area of use. This results in top performance data for precision, operating reliability and ease of cleaning. Failsafe storage of all system parameters Digital signal processing for best detection Process- and condition monitoring Standardised system for a wide area of use Robust construction for maximum lifetime Highest precision in long-term operation Fast ejector for minimized material loss Dismantle without tools All components are easily accessible

Request for a quote

MICRO-EPSILON

Germany

For the production of reeled resistors or sheet goods on roller head installations the thickness measurement is an essential factor for controlling and monitoring the production process. Applying systems of the RTP series, the profile thickness can be measured in various accuracy classes, thickness ranges and material widths.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Datapaq® Reflow Tracker® temperature profiling system travels through the process, enabling you to monitor wave and reflow soldering, as well as vapor phase, selective soldering and rework stations. Comprised of specifically designed thermocouples, data loggers, protective thermal barriers and Insight software, this system will help you optimize product quality, expedite process setup, increase yields and minimize the need for rework. For more details and specifications, download the Reflow Tracker System brochure. Insight Software for Reflow Tracker available in Basic, Standard and Professional versions Insight software is an easy-to-use analysis package designed by Datapaq to meet the needs of the electronics assembly industry. With a typical reflow soldering profile lasting only six minutes, users don't want to spend additional time analyzing the profile. Insight Software ensures that the user is presented with a detailed analysis immediately and it comes

Request for a quote

INFICON GMBH

Germany

UNLOCK YOUR PROCESS Unparalleled Performance for Increased Yields and Maximum Uptime The ever increasing price of silicon wafers and demand for finished products means that scrapped wafers cost more than ever before. Thus, understanding your process and monitoring for defects has become a much higher priority in semiconductor fabrication centers. The Transpector MPH Gas Analysis System is designed to unlock your process with industry leading performance for all of your gas analysis applications to help maximize chip yields and minimize tool downtime. Combined with a low overall cost of ownership and high mean-time-between-failures, Transpector MPH helps your bottom line more than any other residual gas analyzer (RGA) on the market. INFICON has leveraged its expertise in gas analysis process control equipment to create an RGA with industry-leading data collection speed, minimum detectable partial pressure and signal-to-noise ratio. All this, without sacrificing any of the...

Request for a quoteResults for

Process monitoring - Import exportNumber of results

163 ProductsCountries

Category

- Sensors (14)

- Measurement and control instruments (9)

- Chemical and pharmaceutical industry - machinery and equipment (8)

- Pad printing (5)

- Rubber - industrial machinery and equipment (5)

- Measurement - Equipment & Instruments (4)

- Automation - systems and equipment (2)

- Brakes, servo-brakes and accessories (2)

- Compressed air tools and systems (2)

- Cooking and smoke-curing equipment for delicatessens (2)

- Dosing pumps (2)

- Electrical & Electronic Components (2)

- Electronic components (2)

- Goods handling systems, continuous (2)

- Heat detectors (2)

- Lighting, street, industrial and commercial (2)

- Machine tools - metal machining (2)

- Monitoring and control equipment (2)

- Nuts (2)

- Road transport - logistical services (2)