- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precision components

Results for

Precision components - Import export

KEBA FASTENINGS

Germany

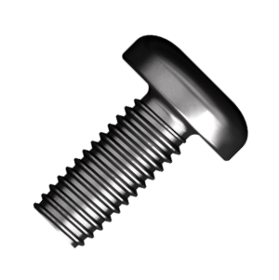

The Micro Screw range consists of self-tapping and metric standard screws along with metric threads according to customer-specific applications. When the trend is to minimize the size and weight, these durable and small dimensioned screws provide the required competitive advantage where even the smallest gram and millimeter counts. FEATURES & BENEFITS • Diameter range of M 0.8 – M 2.6 • Lengths reaching up to 10x the thread diameter • Capability of various thread heads • Reliability with 50ppm • Thread-forming of even the smallest components for direct assembly • Cost-effective as additional inserts and add-ons are redundant • Time effective as cycle times are minimized in work-flow • Assembly is possible in the smallest of installation spaces • Available in plastic, light metal, and steel materials for use in automated assembly The Micro Screw is available as self-tapping, metric standard as well as customer-specific applications with metric threads.

Request for a quote

KEBA FASTENINGS

Germany

provide precise performance for small components with a range consisting of self-tapping and metric standards as well as any threads according to customer specific applications. Diameter range of M 0.8 – M 2.6 Lengths reaching up to 10x the thread diameter Capability of various thread heads Reliability with 50ppm Thread-forming of even the smallest components for direct assembly Cost effective as additional inserts and add-ons are redundant Time effective as cycle times are minimized in work-flow Assembly is possible in the smallest of installation spaces Available in plastic, light metal and steel materials for use in automated assembly The Micro Screw is available as self-tapping, metric standard as well as customer-specific applications with metric threads.

Request for a quote

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

The KS Twin Gear helical bevel gearbox is a high performance and precision gearbox. This two-stage gearbox available in ratios up to 75:1 is very space-efficient and suits an array of applications. High torsional stiffness and low backlash ensure a high transmission accuracy. Features and benefits: Precision component parts Suitable for high input speeds Extremely compact design Motor mounting via coupling High torsional stiffness High torque Low-noise hypoid bevel gears

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The MMC 600/900 is the basis for a series of machines that, via several accessories and options, can be fully customized to individual needs. In the basic version the machine consists of a main X-axis featuring a linear air bearing (feed axis), a linear roller bearing Z-axis (infeed axis) and the milling spindle (air bearing) mounted on top of the Z-axis. The main application is face milling of optical and mechanical precision components. Several accessories like a Y-axis, an A-axis and/or C-axis are available, thus expanding the range of machinable parts to microstructures, lenticular structures, spheres, polygons and so on. Accessories, like vacuum chucks, different milling spindles, touch probes for part thickness measurement and even machine interferometers for insitu measurement of workpiece shape, make the MMC 600 and 900 machines an effective tool. Besides further accessories, there is the possibility to make customized solutions, to adapt the machine to your needs.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

In the basic version the MMC 5000 consists of a main X-axis featuring a linear air bearing (feed axis), a linear roller bearing Z-axis (infeed axis) and the milling spindle (air bearing) mounted on top of the Z-axis. The main application is face milling of optical and mechanical precision components. A Y-axis is available as an option. Another useful accessory is a second milling spindle, used perpendicular to the first one, thus allowing for the machining of two sides of a workpiece to perpendicularity in one setup. Accessories, like vacuum chucks, different milling spindles, touch probes for part thickness measurement, machine interferometers and other sensors for insitu measurement of workpiece shape and roughness, make the MMC 5000 machines an effective tool. In addition, various sensors are available for measuring of the workpiece geometry and surface quality during the manufacturing process.

Request for a quote![GearSystems [2.0]](/filestore/vig280/opt/product/4c/de/de-dg-system_7cee2ba1.jpg)

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

System Solutions for Rack and Pinion Applications As a supplement to the well-known gearbox product ranges, MS-Graessner offers system solutions in the field of rack and pinion applications for mechanical and plant engineering. The DynaGear, KS-TwinGear, DynaGear DG and DynaGear PL systems consist of precise system components developed for automation technology. These include: low-backlash precision gearboxes spur gears toothed racks lubrication systems 4 sizes from T2B= 53 Nm to390 Nm Feed forces up to 11 kN 2 precision classes Input speeds up to n1max = 6000 min-1 Feed speeds up 6 m/s Gear ratios from 5:1 to 15:1 Spur gear modules from to m2 bis m4

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

Spit nozzle SD 17: version for pin-point and linear application The pneumatically operated SD 17 is also available as a spit nozzle version. The fully spray valve has been specifically developed for pin point and linear application of oils, release agents and other low-viscosity media; it maintains its precision at certain distances between the nozzle and the application object. The spit nozzle SD 17 is particularly suitable for precision lubrication tasks of components and tools; it can also be setup for higher viscosities via an optionally selectable heating unit.

Request for a quote![GearSystems [2.0]](/filestore/vig280/opt/product/6d/7d/ks30kh_815e350b.jpg)

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

System Solutions for Rack and Pinion Applications As a supplement to the well-known gearbox product ranges, MS-Graessner offers system solutions in the field of rack and pinion applications for mechanical and plant engineering. The DynaGear, KS-TwinGear, DynaGear DG and DynaGear PL systems consist of precise system components developed for automation technology. These include: low-backlash precision gearboxes spur gears toothed racks lubrication systems 8 sizes from T2B = 225 Nm to 11250 Nm Feed forces up to approximately 200 kN 3 precision classes Input speeds up to n1max = 8000 min-1 Feed speeds up to 4 m/s Gear transmission ratios from 15:1 to 75:1 Spur gear modules from m2 to m8

Request for a quote![GearSystems [2.0]](/filestore/vig280/opt/product/af/c8/dynaGear-Ritzel_67543e7d.jpg)

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

System Solutions for Rack and Pinion Applications As a supplement to the well-known gearbox product ranges, MS-Graessner offers system solutions in the field of rack and pinion applications for mechanical and plant engineering. The DynaGear, KS-TwinGear, DynaGear DG and DynaGear PL systems consist of precise system components developed for automation technology. These include: low-backlash precision gearboxes spur gears toothed racks lubrication systems 8 sizes from T2B= 53 Nm to 2160 Nm Feed forces up to approximately 35 kN 3 precision classes Input speeds up to n1max = 8000 min-1 Feed speeds up to 10 m/s Gear ratios from 3:1 to 100:1 Spur gear modules from m2 to m6

Request for a quote![GearSystems [2.0]](/filestore/vig280/opt/product/84/ee/dynaGear-Eco_0992140d.jpg)

NIDEC GRAESSNER GMBH & CO. KG THE GEAR COMPANY

Germany

System Solutions for Rack and Pinion Applications As a supplement to the well-known gearbox product ranges, MS-Graessner offers system solutions in the field of rack and pinion applications for mechanical and plant engineering. The DynaGear, KS-TwinGear, DynaGear DG and DynaGear PL systems consist of precise system components developed for automation technology. These include: low-backlash precision gearboxes spur gears toothed racks lubrication systems With planetary gear output flange 3 sizes from T2B= 53 Nm to 210 Nm Feed forces up to 8 kN 2 precision classes Input speeds up to n1max = 5000 min-1 Feed speeds up to 6 m/s Gear ratios from 5:1 to 15:1 Spur gear modules from m2 bis m4

Request for a quote

LUTZ PUMPEN GMBH

Germany

The MEMDOS LP motor-driven diaphragm dosing pump is the ideal choice for applications where the pump needs to be integrated into control systems or control loops. A version with an Ethernet-based MODBUS interface is available specifically for integration into sophisticated automation networks, enabling seamless communication and control. Equipped with a robust plunger drive and the option of manual or automatic capacity adjustment, the MEMDOS LP reliably and precisely doses various media such as acids, alkalis, precipitants and flocculants. This flexibility and precision make it a reliable component in various industrial processes. The MEMDOS LP is also available with a double diaphragm system on request, which ensures increased safety and reliability.

Request for a quote

SUPER-FILAMENT EINE MARKE DER ADDITIVE MATERIALS GMBH

Germany

Our advanced manufacturing crafts highly precise, custom-engineered components for technical applications in small series. Precision in 3D Construction and Modeling: Expertise in precise 3D construction and modeling underpins the production of technical production parts in small series. Leveraging advanced 3D printing, we create components meeting high standards of accuracy and functionality. Diverse Material Portfolio for Technical Applications: From classic materials (PLA, PET-G, ASA, ABS) to specialized polymers and fiber composites, our varied material portfolio caters to specific needs of technical production parts. Optimized Manufacturing for Small Series: Our techniques ensure efficient, precise production for small series, balancing cost-effectiveness and quality for swift market entry.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The SLB bandsawing machines from BEHRINGER: A trustworthy partner for workshop and plants. Suitable for cutting tubes, profiles and solid materials made of metal and comparable plastics. Competitive pricing, precision made components, and impressive power. See for yourself. - Mitre cuts are possible from + 30° to – 45° - Scale for setting the exact angle — Clamping of the saw frame with a quickly-tension lever — Downfeed control by a hydraulic flow control valve - Automatic height-setting of the saw frame above the material — Frequency controlled sawblade drive (optional) — Exact cutting

Request for a quote

KÄFER MESSUHRENFABRIK GMBH & CO. KG

Germany

Most modern methods are applied in the production of our high quality Dial Test Indicators. They are both sensitive and shock-resistant. Here are some of the advantages applicable to the whole series: All features of the models reading up to 1 mm measuring range conform to DIN 2270. This applies to all deviation spans, the measuring force and the hysteresis error of the measuring force Automatic change of the direction of measurement Indication clockwise in all types Precise components, running in ruby bearings, warrant highest precision throughout Precision bearing for the lever shaft Body with 3 dovetail slides for clamping the stem and other equipment Body hard-chromed in order to protect the dovetail slides against damage Tungsten carbide ball 2 mm Ø in measuring inserts Dial adjustable by knurled bezel Supplied in a convenient box with transparent lid with 1 stem Ø 8 mm h 6 and 1 spanner for changing the contact points

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 060 Cutting and forming Device for jumper wires Description The Streckfuss model C060 is designed to cut and form 20 to 22 gauge jumper wires. The machine has an adjustable center to center distance and uses interchangeable die sets to vary the cut length. The wire straightener, feed clamp and backlash assembly combined with an adjustable feed stroke produce a precise jumper wire every time. Components

Request for a quote

BENZ GMBH WERKZEUGSYSTEME

Germany

User friendly, stable and very precise. By combining taper concentricity with no backlash with an extremely large planar surface, combined with high torque, BENZ Solidfix® offers a maximum in stability and rigidity, which is even capable of withstanding the demands of milling. The high torque transmission and the highest possible rpms also stress the effectiveness. This is supported by a special clamping mechanism which works centrally, without lateral forces, which in combination with the compact, highly precise components used achieves optimal values for concentricity, rigidity and accuracy in repeatability. Because of its compact design the system is ideal for tools with internal cooling.

Request for a quote

ASSFALG GMBH

Germany

The Pivot magnetic welding angle has a holding angle range from 28 to 270 degrees. The Pivot magnetic welding angle is a universal handyman for smaller welding and assembly work on round and flat material. Through the quick release and a scale, the angle can be set simply and precisely. Components can be clamped on the inside or outside. Each leg can be switched on and off through a rotary switch.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Precision components - Import exportNumber of results

17 Products