- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rotational vibrations

Results for

Rotational vibrations - Import export

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

Rotating Piston Absorbers are displacement absorbers using hydraulic flow resistance. They are used to damp rotational vibrations, e.g. absorbers for ropeway cabins (see VDIRichtlinie VDI 3833 German Association of Engineers, sheet 1). The design is customized. Due to different operating conditions, no standard design is possible. (see also VDIGuideline, VDI 3833 sheet 1)

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

Highly flexible tyre coupling MULTI CROSS RILLO MCR * High torsional flexibility with progressive torsional deflection characteristic * High compensating capability for axial, radial and angular misalignments * Easy and time saving mounting of the coupling hubs thanks to the use of taper bushes * Radial change of the rubber element without axial movement of the coupled machines * Backlash-free torque transmission even in case of alternating directions of rotation * High torsional vibration and shock load damping capability * Noise level insulation * Wear-resistant and maintenance-free

Request for a quote

FRANKE GMBH

Germany

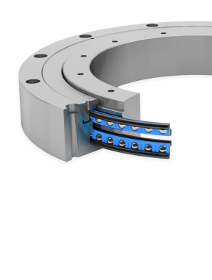

Franke bearing asseblies type LVC are bearing assemblies made of steel, designed as double row angular contact ball bearings with integrated bearing elements. Franke LVC are suitable for highest circumferential speeds. They convince by very high dynamics and a very low rotational resistance. The double row angular contact ball bearings in a 4-point arrangement are preloaded. They are insensitive to shocks and vibrations. The low rotational resistance and the minimal breakaway torque reduce the required drive power. Due to the low coefficients of friction, Type LVC bearing assemblies operate almost maintenance-free and achieve a long service life.

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

Highly flexible coupling with progressive torsional stiffness MULTI CROSS FORTE MCF * Very high torsional flexibility with a progressive torsional characteristic line * High compensation capability of axial, radial and angular misalignment * Backlash-free torque transmission even for reverse rotation * High torsional vibration and shock load absorbing capability * Good removal of heat which may be generated by the damping effect of the coupling * Easy alignment of the coupling * Positive fit between transmission element and hub fl ange to prevent relative movement * Cost-saving spare parts inventory by use of the same element size within one series type

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

MULTI CROSS RILLO couplings are highly torsionally flexible tyre couplings with progressive torsional deflection haracteristic. The salient feature of the MULTI CROSS RILLO shaft couplings is that the coupling hubs are supplied with commercially available taper bushes for nominal torques of up to 11500 Nm. This allows easy and time saving mounting of the coupling hubs on the shaft. Special tools are not required. The most important attributes and advantages of the highly flexible MULTI CROSS RILLO couplings: High torsional flexibility with progressive torsional deflection characteristic High compensating capability for axial, radial and angular misalignments Easy and time saving mounting of the coupling hubs thanks to the use of taper bushes Radial change of the rubber element without axial movement of the coupled machines Backlash-free torque transmission even in case of alternating directions of rotation High torsional vibration and shock load damping capability Noise level...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BALLERSTAEDT & CO. OHG

Germany

An alternative to conductive heat sealing is contact induction sealing, which is particularly suitable for sealing demanding container materials such as e.g. glass, metal or ceramic. An electromagnetic field is built up by a generator via an induction coil that is housed in the sealing head. The molecules of the aluminum foil are set in rotating vibrations, creating heat that is used for the sealing process. Our sealing machines PolySeal Vario PN and PolySeal Vario Twin as well as all fully automatic sealing systems can be equipped with induction technology.

Request for a quote

NITTO KOHKI EUROPE GMBH

Germany

Smooth high speed rotation and low vibration enables precision grinding. Stepless speed change from 0 to 56,500 rpm meets a wide range of grinding applications. Compact & light weight for comfortable operation over long periods of time. Triangular grip fits operator's hand. Special plastic grip prevents cold hands and absorbs vibration. Rear exhaust system.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

Safe, simple, precise The new VibScanner 2 Ex is a nextgeneration, explosion protection system for quickly detecting machine vibration in hazardous work environments. Measuring simultaneously on three axes, the VibScanner 2 Ex sets the benchmark for fast and accurate measurements of machine, gear, and bearing issues. This is the ultimate tool for fast and accurate machine vibration measurements. The VibScanner 2 Ex heightens efficiency and data quality. In just a quarter of the time of a standard datacollector, it precisely measures available data in three axes. Equipped with a triaxial sensor, it requires only one measurement point and the click of a button to begin collecting machine data. This device is ideal for routebased maintenance jobs in environments where explosion protection standards are required. Its rugged magnetic foot of the triaxial sensor fits perfectly on the housing of any motor, pump, fan, or other rotating device, detecting vibration right near the source.

Request for a quote

FLUKE DEUTSCHLAND GMBH

Germany

A unique handheld measuring device with which even untrained personnel can easily and effectively measure machine vibration on rotating machinery. Thanks to its forwardlooking measuring principle and data acquisition across three axes with the triaxial sensor, all relevant condition information is recorded with the touch of a single button. And at a measurement speed that opens up fully new dimensions. Not only is the VIBSCANNER 2 a breakthrough in terms of measurement speed and precision, but also through its robustness and its intuitive operating concept. The intuitive graphical user interface assists the employee en route in taking repeatable errorfree measurements. The device provides him/her with the exact information about the status of the measurement locations and the progress of the route.

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Centrifugal Screening Vibration/rotation screening plants – the solution for fatty, oily and light products The vibration/rotation screening machine enables the screening of products that are difficult to screen and that would smear up screen inserts. This relates in particular to fat-containing and oiled products and products with very light bulk weights. For this purpose, an eddy current is generated by a wing rotating in screening half shells. Through targeted vibration overlays of the the outer screen fabric a seal of the fabric is prevented, thus ensuring a high-quality screening even for procedurally sensitive products. Technical data Screening area 0.5 or 0.9 m² Mesh width: 75-10,000 µm Product-contacting parts: Rustproof materials Cleanability: Completely cleanable Number of fractions: 2 Product feeding: Extractable dosing screw Throughput: Depends on mesh size and the product Number of plants: 2 Areas of application Grinding of soft products without temperature i

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Properties: Filling with gross weighing system Capacity of up to 250 containers/min. Fills metal cans Low space requirement, integration solution for monoblock with a sealing machine Filling process with cup dosing machine Maximum accuracy thanks to precisely manufactured fill heads Rotating carrier segments Vibration over the entire transport area beneath the funnels Mean value controller Max./Min. jam detection Recognition of container top/bottom Gas Flushing “No jar no fill” system Options: Installation of an Optima extraction system for product extraction <1%

ASSFALG GMBH

Germany

The tub vibratory finishing machine, which has a size similar to a washing machine, with a fill volume of 70 l is our standard machine and is ideal for prototypes and small series. A noise protection cover reduces the noise and makes it possible to work in a workshop. The right and left-hand circulation as well as speed regulation from 1,500 to 3,000 rpm provide for various processing possibilities. The abrasive material and workpieces are rotated through the generated vibration. The desired processing process is created through the contact of grinding bodies on workpieces. The programmable timer rounds off the autonomous work process. The machine has a modular construction and can be expanded with an optional paper filter and separator. Both are controlled centrally through the control panel on the TV 95-SL. We recommend the PF440 paper filter for simple and comfortable water treatment. The S95 separator simplifies the separation of grinding bodies and workpieces.

Request for a quote

ASSFALG GMBH

Germany

The circular dryers are used for stainless drying of all types of workpieces. By using the hot-air blower or the indirect heating through heating rods below the tub, a uniform drying of the workpieces and the drying granulate is ensured. The additional advantage is that it brightens, repolishes and degreases workpieces. Both versions can be configured as individual systems in combination with a new vibratory finishing machine or as a module for an existing vibratory finishing machine. The drying medium and the workpieces are brought into a rotational movement through a generated vibration. The desired drying or post-treatment process are created through the contact of the drying medium and workpieces. The workpieces are automatically screened out of the dryer and transported from the device through the optional manual or pneumatic separation equipment.

Request for a quote

ASSFALG GMBH

Germany

The circular trough vibratory finishing machines are ideal for small and large series for different workpieces. A noise protection cover reduces the noise and makes it possible to work in a workshop. The right and left-hand circulation as well as speed regulation from 1,200 to 1,500 rpm provide for various processing possibilities. The abrasive material and workpieces are rotated through the generated vibration. The desired processing process is created through the contact of grinding bodies on workpieces. The programmable timer rounds off the autonomous work process. We recommend a paper filter or a fully-automatic water treatment plant for simple and comfortable water treatment. The integrated separating equipment simplifies the separation of grinding bodies and workpieces.

Request for a quoteResults for

Rotational vibrations - Import exportNumber of results

15 ProductsCountries

Company type