- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- production press

Results for

Production press - Import export

ULBRICH GMBH

Germany

We build production-presses in form of column-presses, pillar-presses etc. after your specification up to a max. force of 1600 tons. According to customer-wish with simple, doubles or triply cylinder system.

BORNEMANN GMBH

Germany

Coining dies made from alloy tool steel for the individual labelling of your products in cold or warm die. The machine dies are hardened annealed in our plant in accordance with the use. This category includes coining dies, signature dies, engraving dies, steel dies or press dies. Production is carried out in accordance with your drawings.

Request for a quote

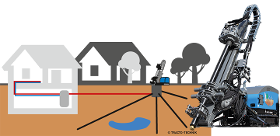

TRACTO-TECHNIK GMBH & CO. KG

Germany

Methods Products Videos Press & References Application partner FAQ Downloads

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

GRUNDOMAT Soil displacement hammers GRUNDORAM Pipe rammers GRUNDOPIT Mini steerable bore rigs GRUNDODRILL HDD systems GRUNDOBORE Auger boring units GRUNDOBURST Static pipe bursting GRUNDOCRACK Dynamic pipe bursting GRUNDOTUGGER 250 GEODRILL - Geothermal energy Methods Products Videos Press & References Application partner FAQ Downloads

Request for a quote

RONIX GMBH

Germany

Ronix segmented granite cutting discs are manufactured by hot press production process with fully automated machines. In comparison to cold press production process, the hot-press cutting wheels can deliver higher efficiency. These circular granite cutting blades have also a longer life cycle compared to others. To provide the users with a great cutting experience, the best possible and highest quality raw materials are used to produce Ronix granite cutters. The unique formulation of materials in the diamond tips of these discs, minimizes friction between the workpiece and the blade which results in a faster and cooler cut

Request for a quote

RONIX GMBH

Germany

Stones and granites are one of the most durable materials in the world. Almost all of the ancient buildings that has remained from various periods in the history, were made of granite and stone. Because granite is an extremely durable and highly resistant material, cutting and shaping plates of granite needs specific tools. However, to do the job, these tools also require cutting disks. This is why we at Ronix produce high-quality and strong granite cutting wheels as accessories. Our Granite Cutting Disks are made of top-quality raw material and with a unique formulation to deliver great performance and be as efficient as possible. Ronix segmented granite cutting disks are manufactured by hot press production process with fully automated machines. In comparison to cold press production process, the hot-press cutting wheels can deliver higher efficiency.

Request for a quote

SCHMITTER HYDRAULIK GMBH

Germany

Assembly immediately upon receipt of order - generally in stock Umbausatz Hydroaggregat Mit diesem Umbausatz kann die Hydraulikpresse S 2.1M Ecoline wie gewohnt mit der Handpumpe oder mit dem ... Category Hydraulic hoses and fittings / Machines and tools / Hose press / Hydraulic unit Product number supplier 43381008

Request for a quote

RONIX GMBH

Germany

Manufactured by hot press production process with full automatic machines which ensures high performance and efficiency -High quality raw material formulation of diamond tips minimizes the friction and delivers a faster and cooler cut -10mm height of cutting rim guarantees an optimum life time -Manufactured by high quality material which optimizes cutting performance and ensures durability -Ideal for all types of granite -Suitable for both wet and dry cutting

Request for a quote

RONIX GMBH

Germany

Ronix RH-3510 & RH-3511 Granite Cutting Discs are manufactured by cold press production process with fully automated machines. These wheels are produces in a way to ensure faster cuts and longer lifetime of the cutting disc itself. To provide the users with a great granite and marble cutting experience, the highest quality materials are used in the production of these Ronix cutting discs. The unique formulation of materials in the diamond tips of these discs, minimizes friction between the workpiece and the blade which results in a faster and cooler cut. Since granite is a highly durable and resistant material, the process of cutting it causes a lot of friction. This is why many people prefer to add water and other liquids to the cutting process to cool down the disc in order to protect it. For this reason, we at Ronix manufacture our granite and marble cutting discs so be suitable for both wet and dry cutting to suit a wide range of consumers’ needs.

Request for a quote

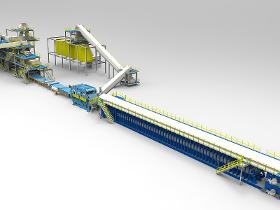

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

User-friendly and intuitive Economical owing to highest availability Variable strap width Unbeatable price / performance ratio Optimal access Intrinsically safe machine, protection door-less concept ASLF 'Anti-Strap-Loss-Function' Constant strap control Strap width 5 - 9 mm, adjustable Automatic strap threading, soft Strap end detection system with automatic discharge of remaining strap Automatic strap tensioning, stepless Strap coil detection with yellow indicator lamp DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam Torque controlled strap tension, adjustable Upstream and downstream interlocks with complete plug connection Conveyor speed steplessly adjustable GreenTech energy concept, low power consumption Bundle stops in longitudinal machine, optional Bundle press, optional Production data analysis via Ethernet/USB SAO 'Safe and Open' - Safe without protection doors SMART TOUCH – Icon control concept Standby mode Wear-free, energy saving...

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

User-friendly and intuitive Economical owing to highest availability Variable strap width Optimal access Intrinsically safe machine, protection door-less concept Unique, the lateral strapper principle in the inline strapper ASLF 'Anti-Strap-Loss-Function' Constant strap control Strap width 5 - 9 mm, adjustable Automatic strap threading, soft Strap end detection system with automatic discharge of remaining strap Automatic strap tensioning, stepless Strap coil detection with yellow indicator lamp DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam Torque controlled strap tension, adjustable Upstream and downstream interlocks with complete plug connection Conveyor speed steplessly adjustable GreenTech energy concept, low power consumption Bundle stops, optional Bundle press, optional Production data analysis via Ethernet/USB SAO 'Safe and Open' - Safe without protection doors SMART TOUCH – Icon control concept Standby mode Wear-free, energy saving...

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

Economical owing to highest availability Robust and extremely low maintenance Easy handling Minimum space requirement Best cost / benefit ratio ASLF 'Anti-Strap-Loss-Function' Constant strap control Strap width 5 - 12 mm, either DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam Torque controlled strap tension, adjustable EPP 'Exact Product Path' Conveyor speed steplessly adjustable For use with PP and PET strap GreenTech energy concept, low power consumption Intuitive touchscreen operating concept Machine movable MFT 'Mono-Frame-Technology' Bundle press, optional Production data analysis via Ethernet/USB SAO 'Safe and Open' - Safe without protection doors SMART TOUCH – Icon control concept Table height steplessly adjustable Bundle flow control Wear-free, energy saving direct-drive-motors Low maintenance and low wear strap arch Many specific options available, easily configurable

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

User-friendly and intuitive Economical owing to highest availability Robust and extremely low maintenance Powerful Maximum flexibility & adaptability 5000 bundle recipes ASLF 'Anti-Strap-Loss-Function' Constant strap control Strap width 5 - 9 mm, adjustable Automatic strap threading, soft Strap end detection system with automatic discharge of remaining strap Automatic strap tensioning, stepless Strap coil detection with yellow indicator lamp DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam Torque controlled strap tension, adjustable Upstream and downstream interlocks with complete plug connection EPP 'Exact Product Path' Conveyor speed steplessly adjustable GreenTech energy concept, low power consumption MFT 'Mono-Frame-Technology' Bundle stops, optional Bundle press, optional Production data analysis via Ethernet/USB SAO 'Safe and Open' - Safe without protection doors SMART TOUCH – Icon control concept Wear-free, energy saving...

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

User-friendly and intuitive Economical owing to highest availability Robust and extremely low maintenance Powerful Maximum flexibility & adaptability ASLF 'Anti-Strap-Loss-Function' Constant strap control Strap width 5 - 9 mm, adjustable Automatic strap threading, soft Strap end detection system with automatic discharge of remaining strap Automatic strap tensioning, stepless Strap coil detection with yellow indicator lamp DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam Torque controlled strap tension, adjustable Upstream and downstream interlocks with complete plug connection Conveyor speed steplessly adjustable GreenTech energy concept, low power consumption Signal light tower: operation and failure MFT 'Mono-Frame-Technology' Bundle stops, optional Bundle press, optional Production data analysis via Ethernet/USB SAO 'Safe and Open' - Safe without protection doors SMART TOUCH – Icon control concept Wear-free, energy saving...

Request for a quote

SIGNODE PACKAGING SYSTEMS GMBH - BUSINESS UNIT SMB SCHWEDE MASCHINENBAU

Germany

Economical owing to highest availability Variable strap width Optimal access Intrinsically safe machine, protection door-less concept Unique, the lateral strapper principle in the inline strapper 5000 bundle recipes ASLF 'Anti-Strap-Loss-Function' Constant strap control Strap width 5 - 9 mm, adjustable Automatic strap threading, soft Strap end detection system with automatic discharge of remaining strap Automatic strap tensioning, stepless Strap coil detection with yellow indicator lamp DAT 'Direct-Access-Technology' The exclusive eject function avoids strap jam Torque controlled strap tension, adjustable Upstream and downstream interlocks with complete plug connection EPP 'Exact Product Path' ETS 'Easy to Service' - Maintenance while production Conveyor speed steplessly adjustable GreenTech energy concept, low power consumption High-Speed-Kit, optional Bundle stops, optional Bundle press, optional Production data analysis via Ethernet/USB SAO 'Safe and Open' - Safe without...

Request for a quote

RONIX GMBH

Germany

Manufactured by hot press production process with full automatic machines which ensures high performance and efficiency -High quality raw material formulation of diamond tips minimizes the friction and delivers a faster and cooler cut -10mm height of cutting rim guarantees an optimum life time -Manufactured by high quality material which optimizes cutting performance and ensures durability -Ideal for all types of granite -Suitable for both wet and dry cutting

Request for a quote

SPIROL

Germany

Since the development of coil springs in turret tooling, engineers have been challenged to increase the productivity of turret presses even further. In a traditional press, the option of material type and material thickness is limited by the coil springs inability to produce a high force in a short linear distance. When this performance is necessary, coil springs will have a negative effect on the quality of the formed product and efficiency of the manufacturing process. SPIROL® Disc Springs are the solution to form thick materials, large extrusions, and more complex designs. When stacked in series, they are capable of providing a greater, more consistent stripping force than coil springs and require less space. They have become an instrumental component in the advancement of turret punch press tooling. Visit www.SPIROL.com to learn more!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

CRAEMER GMBH

Germany

Craemer is a specialist for constructing and manufacturing complex metal components and a well-known international supplier for the automotive, commercial vehicle, large domestic appliance and heating industries. The sheet metal components are sold to leading car producers, such as BMW, Mercedes Benz, GM, Volkswagen and Audi. Miele and other world brands are being supplied with white goods. The Craemer Group is one of the leading European manufacturers in the high volume serial production of car-modules, particularly components for seating structure and seatbelts. We process: sheet steel, high-strength sheet steel, high-grade steel and aluminium sheet Manufacturing process: hydraulic and mechanical presses with progressive die, transfer and servo direct technology as well as modern facilities for assembly production. Press capacity of between 3,150 and 25,000 kilonewton at a maximum table-length of 8,000 millimeters

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

This workstation enables the manual serialisation of drug packages and their aggregation into shipping cases. For this purpose, each individual box is first printed with order-related serialisation data by a thermal inkjet printing system as it passes by and then manually placed in a shipping carton. As soon as it is filled, the downstream thermal transfer label printer creates an individual serialisation label. The correct print data and print quality are permanently monitored by a vision system. The operator places the medicine products to be serialized on a reference edge at the infeed. As soon as the thermal inkjet printer has printed the serialisation data, the integrated vision system checks that the data is correct. If an error is detected (e.g. insufficient grading), the product stops at a certain position marked by red LEDs. The removal of the rejected product must be confirmed by pressing a button on the HMI.

Request for a quote

ANDRITZ KAISER GMBH

Germany

ANDRITZ Kaiser produces highly precise presses for the metal forming industry, thus increasing productivity, quality, and lifetime and decreasing overall operating costs. ANDRITZ Kaiser has delivered more than 8,000 presses for numerous customers world wide, each different in its application. A large number of factors have to be taken into account when deciding on the right press: technical requirements from the product, expected productivity, technical requirements on the press line, integration into the existing production lines, fixed and running costs, process control, fast availability of maintenance/service, availability of spare parts – all these considerations influence mainly the total cost of ownership. Our press solutions are: Conventional high speed presses from 630 kN up to 4,000 kN Conventional stamping and deep drawing presses from 1,000 kN up to 8,000 kN Cutting presses from 1,600 kN up to 6,300 kN Heavy presses from 10,000 kN up to 25,000 kN Servo presses from...

Request for a quote

SIMPAC EUROPE GMBH

Germany

Hydraulic presses are suitable for the high-precision forming of various parts, whereby the maximum press capacity is available in every position of the slide. In combination with their flexibility in terms of slide speed and dwell time, they are also particularly suitable for press hardening applications. Overview: ● Press capacity: 1,500 - 25,000 kN ● Part size: small, medium, large ● Application: for the production of drawn parts or as part of a press hardening line Description and benefits: ● Slide movement either pressure and / or travel-dependent ● Specially designed hydraulic system without shift shock during operation ● Motorized oil circulation with cooling or heating unit The models for press hardening are available in 8,000, 12,000 or 16,000 kN and come with a newly developed combination of servomotor and hydraulics that allows higher speeds in the closing and return movement of the slide.

Request for a quote

SIMPAC EUROPE GMBH

Germany

The eccentric drive of the DTE series is primarily suited for cutting, blanking, forming and embossing operations. Its characteristic sinusoidal slide motion curve makes it ideal for flat and semi-flat parts. The proven and continuously optimized technology ensures reliable production processes. Overview: ● Type: Eccentric presses ● Press capacity: 8,000 - 25,000 kN ● Part size: large ● Slide kinematics: crank / eccentric motion ● Application: as a single press system either as progdie or transfer mode, as well as a press line Features and benefits: ● High part quality due to rigid, FEM-optimized press design ● The outside located pressure points and a long 8-fold slide guiding system absorbe off-center loads, spare press and die and ensure a constant part quality ● Extensive range of optional equipment, such as die cushions, pneumatic ejectors or moving bolsters for a faster die change

Request for a quote

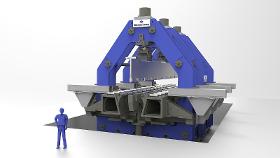

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp is number one in tailor-made plants for the leading manufacturers of pipeline pipes. These large-diameter pipes with longitudinal weld seams are manufactured using crimping, U-forming, and O-forming presses. Compared to other processes on the market, these three presses achieve high production outputs of up to 30 pipes per minute regardless of the pipe diameter. For these large presses featuring our proven metal frame construction, the heavy component parts and tools are manufactured in our in-house foundry. The three hydraulic presses present the essential forming units of a modern production line for longitudinally welded pipes with lengths of up to 18 m in three forming steps. For each of the three forming steps, Siempelkamp oers the optimal press and the associated equipment for the forming line (e.g., pipe transport, lubrication, measuring).

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Using a ContiTherm preheater upstream of the ContiRoll® press increases the production output of a wood-processing plant signicantly. It is an additional component integrated into the forming line and serves to preheat the mat before it is transferred to the ContiRoll® infeed to just below the temperature at which the glue starts to cure. A steam-air mix is conveyed through the mat. During this process, the steam condenses at the bres or particles, heating them up. The preheating temperature can be set most accurately by varying the steam content of the mix. The machine is separate into two to four sections (seen in working direction). Depending on the application these sections are designed for a unidirectional or a bidrectional steam injection or equipped with hot platens heated by thermal oil. The width of the steam boxes in an MDF-plant can be extended by additional segments to optimise steam-air conveyance.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Following product changes or a surface defect detected by the monitoring equipment, the aected mat section has to be rejected and discharged in time before reaching the ContiRoll®-infeed. This is ensured by Siempelkamp’s reject mat system. It is an in-line element of the forming line. Thanks to its modular design, it can be adjusted to the product parameters, enabling reliable press protection and a quick and material ecient plant restart. Features Drive/reject mat unit including track support Reject mat hopper Integration in the belt drive station Motor-adjustable table including belt deection nose Motor-adjustable belt cleaning brush Advantages Distance-controlled activation for an optimised material discharge and minimised rejects volume Options Including disintegrating rollers Including dust ap Hydraulic reject mat drive Nose stroke 3000 mm or 4000 mm

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

A press for all processes Beside the pressing systems for industrial production, Siempelkamp manufactures laboratory press systems – both “try-out” presses for laboratoryscale tests with a starting pressing force of 150 t as well as presses for “fullscale testing”. The laboratory press systems are designed for maximum exibility. With it, all processes of composite production can be investigated. For example, it can be investigated whether press technology is an economic alternative for “autoclave” processes. All processes SMC with glass ber or carbon ber RTM PCM Organo-sheet consolidation Thermoplast forming Hybrid forming Integrated molding and joining of hybrid materials All control methods Force control with position monitoring Position control with force monitoring Each process step can be individually dened and programmed: All relevant process data are recorded and displayed.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

CellTRON® FOR MAXIMUM FILTRATION REQUIREMENTS The basis of this plant is a membrane filter press. The new product series is equipped with an innovative filter press emptying system with lifetime error message, an automated filter cloth washing system with implemented CIP cleaning function as well as an automatically opening and vacuum-proof housing. In contrast to conventional filter presses, this new development guarantees an almost gastight encapsulation of the filter press. The filter press thus meets the specific requirements for dewatering special (metal) sludges. In addition to standard configurations for battery cell production, this technology series is also suitable for demanding applications that require the highest safety and efficiency standards. These include volatile, dust explosive products as well as substances with toxic and radioactive properties but also pharma food products and hot suspensions (≥130°C).

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Design and production of press-systems for the rubber industry is one major core competences of Siempelkamp More than 100 years of experience in rubber press lines More than 100 years ago, we put in operation the first conveyor belt press on the market. Only 20 years later, the first large vulcanizing press with a closed frame construction went successfully in operation. Even today, our presses and systems for the rubber industry have unqiue advantages: Durability, speed, high availability and efficiency, which are the most important arguments for our customers to choose a Siempelkamp plant. Proven technology that is trusted in the rubber industry With our broad expertise in the fields of rubber processing industry, we are the world market leader for steel cord and conveyor belt presses. A large part of the conveyor belts used around the world are manufactured on our equipment. Despite heavy loads, these conveyor belts always have to have best straight-running stability.

Request for a quote

ASTRONOVA GMBH

Germany

The T2-C is the first-ever high capacity, high volume tabletop label press capable of delivering precision over long runs. Producing consistent, high-volumes in 24/7 production, the T2-C opens new doors in the label printing industry. A one-of-a-kind tabletop label printing press that incorporates the features and functionality of a traditional large production press into a footprint small enough to fit into any size print department. The T2-C bridges the gap between compact, inexpensive desktop label printers and expensive, large commercial label press to provide a highly flexible and productive solution for printing medium to large runs labels. Equipped with economic 2-liter ink tanks, the T2-C provides a perfect combination of increased print accuracy and reduced price of ink, offering significant cost savings over the life of the printer.

Request for a quoteResults for

Production press - Import exportNumber of results

54 ProductsCountries

Category

- Aluminium and aluminium alloys (8)

- Pipes and tubes, aluminium (8)

- Tools, pneumatic (5)

- Sections - non-ferrous metal (4)

- Metal industrial presses (3)

- Forming - steels and metals (2)

- Wood veneer - machinery and equipment (2)

- Presses, hydraulic (1)

- Chemicals and pharmaceuticals - packaging machinery (1)

- Bar codes - printing machines (1)

- Drainage systems and equipment (1)

- Folding - steels and metals (1)

- Forming, rubber - machinery (1)

- Haircare products (1)

- Packing and packaging - machinery and equipment (1)

- Rivets (1)

- Screw cutting - steels and metals (1)