- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mechanical belt

Results for

Mechanical belt - Import export

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper PU molded timing belts (form belts), which are cast in special molds, are made of abrasion-resistant polyurethane and high-strength steel cords (or aramid cords). The cast PU timing belt is an exact replica of its mold. Consequently, high pitch accuracy along the entire length of the belt is realized. They are particularly well suited for smooth running and high speeds. By combining high-quality materials and this modern production method, the resulting timing belts exhibit supreme mechanical, chemical and physical properties. Mechanical properties: Low longitudinal tolerance Longitudinal stability, negligible elongation Form-fit, synchronous running Low noise High abrasion resistance Favorable performance-weight ratio Chemical properties: Good ageing resistance Operating temperature range from -30°C to +80°C Resistant to simple oils, greases and gasoline Applications All types of drives Office machines Textile machines Wood-processing machines

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper open-ended PU timing belts are made of abrasion-resistant polyurethane and high-strength steel cords or aramid cords and are available in open lengths. These timing belts are very suitable for synchronous conveying and positioning applications because they have very high flexibility and can be made with many different tooth shapes and materials; when combined with different tension cords, innumerable applications are possible. Keiper open-ended PU timing belts can be produced endless welded and by the meter in almost all lengths and widths. Based on this combination of high-quality materials and production methods, these belts exhibit outstanding mechanical, chemical and physical properties. Endless welded timing belts are available in any length. Welded PU timing belts primarily are used in conveying technology.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Keiper profiles and cleats Many special, innovative tasks required in the material flow, such as pacing, separating or positioning, can be realized by adding profiles/cleats and entraining elements to the belts. Profiles and entraining elements are made of the same high-quality polyurethane as our timing belts, are mechanically processed as sheets or injection molded. They are available in different blends and degrees of hardness, with glass-fiber reinforcement and in a matching color. The profiles and entraining elements are homogeneously fastened to the belt by welding or glueing. In view of our production methods, the cleats can be formed into any shape.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The latest development in lifting platform technology is based on mechanical drive technology using belts. Hydraulic oil is not required. Due to a patented catch system, BELT-LINE meets the safety requirements laid down in DIN EN 1570. The combination of exemplary positioning accuracy, smooth running and long service life is the reason the BELT-LINE is an economical precision solution, and not only for sensitive areas. Exemplary smooth running BELT-LINE convinces with a low noise and harmonious movement sequence, paired with maximum lifting speed and positioning precision. Minimum maintenance time and costs without hydraulic oil In particular in sensitive areas, the robust BELT-LINE technology with its long operating life is the best possible solution. The low-wear components can be quickly replaced due to the modular design. Excellent load change behaviour In the design phase, particular emphasis was placed on developing an excellent load change behaviour. The resilient suspension behaviour is only surpassed by LAWECO push-chain lift platforms.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

The innovative LAWECO CHAIN-LINE lifting platform technology unites all advantages of belts and spindles. Mechanically driven by a push-chain, this technology achieves maximum performances without the use of hydraulic oil. Due to a particularly harmonious motion sequence and the excellent load change behaviour in each lift position, the CHAIN-LINE is the preferred solution for designers who place an extremely high value on efficiency and precision for their area of responsibility. Unsurpassed precision LAWECO push-chain lifting platforms convince with a load behaviour and maximum positioning precision which were almost unachievable in the past. Unrestricted availability Almost maintenance free, the robust and low failure construction permits fast component replacement. Safety for the environment and employees The intelligent design does without hydraulic oil. Optional contact rails and bellows increase safety.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IFA TECHNOLOGY GMBH

Germany

At IFA Technology we use all types of pumps available on the market for conveying liquids. We consider all necessary requirements for the safe and reliable conveyance of your products. Solids can be conveyed mechanically, pneumatically and hydraulically. For mechanical conveying, screws, conveyor belts, elevators, vibratory troughs or tube chain conveyors are used. Pneumatic conveying is mainly applied in the chemical and pharmaceutical industries as well as for conveying granulates in plastics processing and the food industry. The pneumatic conveyance process is carried out by suction and compressed air, i.e. by vacuum or positive pressure, and is mainly used when sensitive substances are transported. Heavy substances such as cement, sand or gravel are mainly transported by positive pressure.

Request for a quote

IAI INDUSTRIEROBOTER GMBH

Germany

The DDA Direct Drive Motor is a rotary actuator that directly drives a rotary table with a motor without using any speed reducing mechanism such as a belt or reduction gears. Eliminating the speed reducing mechanism explains why high speed and excellent response can be attained with such a compact frame. The series includes models designed for high torque and high payload up to 90 or 270 kg. This makes it very easy, for example, to integrate rotary indexing tables in an automation system.

Request for a quote

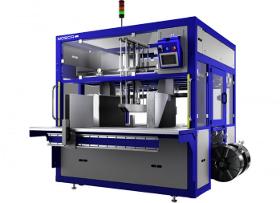

MOSCA GMBH

Germany

• SoniXs Utrasonic sealing unit in standard-6 version • High availability due to controlled frame • 5-sided electromechanical package alignment • Continuously adjustable conveyor speed • Laterally driven transport belts • Driven top belts • Electro-mechanical package stop and hold-down device • Intuitive user guidance via colored touch panel with ergonomic positioning options • ATR – Automatic cycle rate regulation • Easy maintenance due to automatic removable strapping unit • Automatic machine adaptation to package dimensions via adjustable recipes • CE marking inclusive conformity declaration

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Good mechanical properties of a particleboard require core layers made of homogeneously distributed, consistent-quality particles. The mechanical forming heads by CMC Texpan are ideal because they always guarantee consistent particle distribution at the right time. They are called Cageformer heads. Features, function Upstream disc screen for discharging oversize or glue clots Metering bins with adjustable rakebacks Bin bottom belt with speed control belt scale Mechanical Cageformer head incl. 4-6 proled distributing rollers distributing plates 4 cage rollers Advantages No separation eect on the core-layer material Improved distribution in transversal direction Easy cleaning Variants, options Format adjustment forming chamber side wall adjustment recycling of the excess particles Inline correction of transversal distribution

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

mechanical belt connectors for use with most PVC, rubber and steel elevator belts, e.g. Supergrip belt connectors Easy to install system with 50 mm segment widths Four versions for up to 1,250 kN/m without limiting belt strength Max. temperature 80ºC, lock nut with nylon insert (standard) Type BC belt connector for steel mesh belts Four versions for up to 2,500 kN/m belt tensile force Maximum stability using high load bolts with self locking nuts Top quality construction in steel and extruded aluminium

Request for a quoteResults for

Mechanical belt - Import exportNumber of results

11 ProductsCountries

Company type