- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vertical systems

Results for

Vertical systems - Import export

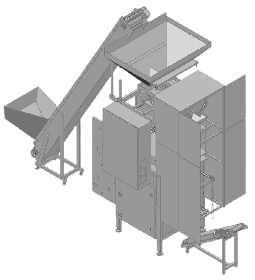

CHALLENGER INDUSTRIAL SOLUTIONS GMBH

Germany

Challenger 100A is fully automatic vertical system designed for filling and packaging of food products (like frozen vegetable) in Nylon film

Request for a quote

KULLEN-KOTI GMBH

Germany

Our brushing machine type BM 1138 has been constructed previously for heavy-duty conveyor belt cleaning in coal mines and foundries. Today we supply it for almost all kinds of industry where conveyor belts have to be cleaned. BM1138-characteristics The particular criteria are: - rugged machine core in welded construction. - high cleaning performance. - minimum belt wear. - small assembly dimensions. - easy retrofitting. - simple mounting to all carrier systems. - integrated vertical adjustment of roller brush. - exchange of the brush coils without removing the roller brush. The brushing machine can be installed at the converyors according position 1-8.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The application range includes everything from processing of viscous components to paste-like products with poor flow. The range of food applications is exceptionally broad and there are also various applications for the pharmaceutical industry. The conical shape permits thorough residue-free discharge. The wet mixer system is a vertical mixing system for batch processes. The geometry of the conical or cylindrical mixing vessel, the arrangement and shape of the tools and their peripheral speed are adapted to each other in all sizes, resulting in effective mixing of all components. Depending on the process engineering tasks, the individual mixing tools are combined to form one tool both for material transport and for dispersion and disagglomeration processes. The installation height in the vessel is adjustable within a wide range. An adjustable deflector can be used to affect the product movement in a systematic fashion.

Request for a quote

BEHRINGER GMBH MASCHINENFABRIK UND EISENGIESSEREI

Germany

The automatic mitre bandsaws from BEHRINGER are saws to really get things moving. Particularly when it comes to classical series production such as cutting to fixed lengths and mitre sawing in automatic mode. And also when cutting layers and packages they make a good impression. By their excellent cutting performance and short nonproductive times, your productivity can be increased significantly. Using an NC controlled feed gripper in conjunction with an NC controlled saw frame mitre box, fully automatic mitre cuts can be performed on both sides. The PC control system provided as standard makes for extremely simple menu-prompted operation of the saw and peripheral devices. The BEHRINGER mitre bandsaws contain many useful features already in the basic price: - Convenient PC control - Fast NC-controlled mitre system - Vertical clamping unit - NC-controlled feeding gripper with 3.000 mm feeding length in single stroke - Spray mist cooling system

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

The FX-HV Horizontal-Vertical System will meet with its diverse setting almost any need. Overall height and focus can be adjusted by plug pins. Likewise, the device also can be used for up to 20% of its rated load without engaging under pads.The support pins are positioned in a way so that standing blanks can be struck, which, for example, is often required on the saw. Likewise lying discs and sheets can be placed. For horizontal transport, the system has a lifting eye on the back. The steel structure is completely coated, and the stable FX Lifting magnet ensures maximum safety. Special dimensions are available on request.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Coating for warm forging and hot forging on hatebur presses. Our modular design kits enable you to safely coat diameters from 15mm to 160mm. A system developed by Jerko is also used to safely coat the front sides. Whether horizontal or vertical coating, with our systems you are always on the right side.

Request for a quote

LEICA MICROSYSTEMS

Germany

The fully apochromatic zoom system with apochromatic objectives, offers best contrast, color fidelity and richness of detail. Outstanding light transmission due to the large zoom range from 0.57x to 3.6x. The parallax-free 2D view, due to the vertical beam path, is perfect for photography and image processing. The resolution up to 1500 lp/mm generates sharp and detailed images. Facilitated handling of the sample due to the large working distance (e.g. 97 mm with the 1.0x objective). The integrated iris diaphragm adjusts the depth of field.

Request for a quote

HERBERT WALDMANN GMBH & CO. KG

Germany

TAMETO – this laterally mounted luminaire produces completely shadow-free lighting or an intended shadow effect, as desired. This can, for example, make fine surface irregularities visible. Of course, lateral luminaires are also suitable when more light is needed for certain visual tasks. TAMETO luminaires are mounted on the vertical pillars of the system workplace at the desired height and the desired beam angle using the supplied mounting angle brackets. • Maintenance-free LED technology • Extremely homogeneous, glare-free and flicker-free light • Light exit with conical prismatic structure for perfect glarefree lighting • Robust aluminium housing • Closed construction protects the inside of the luminaire and keeps the work surface clean • Also available in ESD design

Request for a quote

HERBERT WALDMANN GMBH & CO. KG

Germany

With lateral mounting of TAMETO luminaires, completely shadow-free illumination or a desired shadow effect can be achieved. This can, for example, make fine surface irregularities visible. Of course, lateral luminaires are also suitable if more light is needed for certain visual tasks. TAMETO luminaires for lateral mounting are mounted at the desired height and at the desired angle of illumination on the vertical pillars of the system work station using the supplied mounting brackets. • Extremely homogeneous, glare-free, flicker-free light • Maintenance-free LED technology with a service life of up to 50,000 hours and more • Closed construction protects the inside of the luminaire and keeps the work surface clean • Extremely robust aluminum housing • Up to 60 % energy savings • Also available in ESD design

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel vertical lifeline system is designed for permanently-installed, standard ladders made of steel or aluminium (welded-on or crimped rungs) and is simply clamped onto the rungs of your ladder. We also offer an optional model with a longer protrusion (130 cm) which allows the user to climb on and off safely. EN 353-1:2018 (incl. in former times CNB/P/11.073) Suitable for simultaneous usage by 2 individuals (1 person per glider Fixed guide with stainless steel cable (8 mm) A range of top section protrusions available - up to 130 cm Specially-designed vertical ladder glider with a blocking mechanism to apply the brakes in the case of a fall For rungs measuring max. 3.5 cm x 3.5 cm; other sizes available upon request

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple bottles size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Continuous cleaning and blowing rotary system Hightech sensors HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Vertical blowing system. Servo conveyor system

Request for a quote

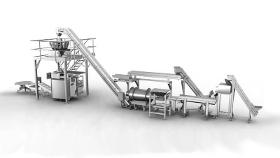

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple ointment viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Cheese chopping machine SCADA and HMI with a touch screen system Hardened stainless steel slicer and 3d chopping system Cups feeder system Antistick powder processing system Vertical conveyor transfer system Automatic suppress distribution system Electro pneumatic weighing cells 3 levels weighing cells Weighing tower Packaging machine Compact design Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple Bottles and caps sizes, types and shapes Type of metal used S.S 316/304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION Flow meter system “ Krohne “ Double conveyor system 8 diving nozzle filling system Caps transferring vertical conveyor Vibrator caps feeder Herma double head labeling system HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear system. Filling capping labeling machine .

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple Jar and caps size, types and shapes Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION 6 diving filling nozzles Customizable jar filling spaces HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request UL, CE, GMP, FDA, ASME. Available documents up on your request I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear filling system Caps feeding section with vertical conveyor system Capping system Closing system. Servo conveyor system.

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION: High stability on high capacity. Can handle multiple Jar and caps size, types and shapes Type of metal used: S.S 316 / 304 Certifications: ISO 9001:2015, OHSAS 18001:2007, ISO 50001:2011, ISO 45001:2018 SPECIFICATION: 6 diving filling nozzles Customizable jar filling spaces HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear filling system Caps feeding section with vertical conveyor system Capping system Closing system. Servo conveyor system.

Request for a quote

WHITE STEEL GMBH

Germany

Flow meter system “ Krohne “ Double conveyor system 8 diving nozzle filling system Caps transferring vertical conveyor Vibrator caps feeder Herma double head labeling system HMI and SCADA system with touch screen integrated user friendly and simplified software. Available certification up on your request: UL, CE, GMP, FDA, ASME. Available documents up on your request: I.Q (Installation qualification), O.Q Operational qualification), P.Q Performance qualification. Linear system. Filling capping labeling machine .

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer vertical conveying system is used to overcome differences in height in product lines. The gripper technology permits space-saving vertical transport. Bottles, glasses, tins, cartons, bundles, etc. can be transported using this conveying principles. Technical data: —Chain width: 46 mm/114 mm/254 mm —Conveying performance: up to 60,000 units/h —Difference in height: up to 8m/12m/12m —Product weight: up to 15kg/40kg/40kg —Product width: 15 - 200 mm/20 - 450 mm/20 - 450 mm —Solid steel construction in painted or stainless-steel version —Manual width adjustment —Automatic tensioning station for the cleated chain —Central lubrication system for the cleated chain

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MOSCA GMBH

Germany

KKOV 315, Basic Model Laterally friction-weld sealing Height moveable, horizontal arch Sealing unit, moveable laterally to the package PLC control Operation via 7" touch panel 10 freely configurable programs with up to 10 strapping positions Can be integrated into most production lines Potential-free contacts to upstream and downstream machines KOB 315, Special Version Like basic model KOV 315; additionally equipped with 2-side aligning device KOH 315, Special Version Like basic model KOV 315; additionally equipped with 4-side aligning device Options: SoniXs Ultrasonic sealing system Vertical edge protection applicator Three-part signal light including low strap indication Air conditioning equipment Strap sealing unit BSG 4 Data interface KSR-2 DC sealing unit HL sealing unit with floating head Design with operator button in addition to touch panel Structural colour according to RAL-scale

Request for a quote

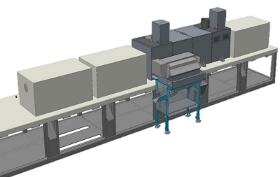

DAMBACH LAGERSYSTEME GMBH & CO KG

Germany

The DAMBACH Vertical Conveyor lifts efficiency to the next level. The free-standing steel construction utilizes warehouse space optimally. The consistent use of poka-yoke techniques and modularcube design allows both fast installation as well as subsequent positioning in confined conditions. Almost any flow of materials can be taken care of with diverse load-handling devices and conveyor elements – two pallets lengthwise or crosswise, a corner transfer module with or without a change of orientation of the conveyed item, and much more. The DAMBACH Vertical Conveyor is one of the highest performing on the market. Each jack can be delivered with preinstallation and decentralized controls. Deepfreeze compatibility up to -28°C comes included at DAMBACH. Compact construction, small lower approach dimensions Inherently stable multiple-column design for heavy loads: up to 3,000 kg Lift speeds up to 240 m/min, lift heights up to 35 m

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

The new FLEXON SafeTopChain was designed with a completely closed upper surface, minimising the risk of crushing in curves or deflections and offering maximum stability for products and workpiece carrier systems. The special surface also enables even the smallest parts to be transported risk-free. Highlights: • Requires the same guides as the normal plastic multiflex chains from the 1700 Series • By using turning disks with a minimum radius of 123.5mm, dynamic friction is replaced by rolling friction; this allows longer conveyors with more curves, as well as vertical/spiral conveyor systems to overcome gradients and providing buffering. • Improved chain geometry enables the use of wider sprockets, thus reducing wear through lower surface pressure when teeth engage.

Request for a quote

SANHA GMBH & CO. KG

Germany

stainless steel heating circuit distributors are suitable for all hot water heating systems in accordance with EN 12828, and for panel heating / cooling systems in accordance with EN 1264, and can therefore be used not only in residential buildings, but also in industrial, commercial and public buildings. They are used for the distribution of water and isolating and balancing flow in heating and cooling circuits. This means that they can be used for the connection of radiators, ventilation / air conditioning units, as well as wall, ceiling and floor heating / cooling systems. Venting, flushing and flow balancing are particularly important to ensure trouble free and optimum operation in floor, wall and ceiling heating and cooling systems. Connection set, vertical, for heat meter, with 3 ball valves, variable adaptor pipe 3/4" 110 mm (1" 130 mm), tee for sensor

Request for a quote

METZEN INDUSTRIES GMBH

Germany

Ideal for use in refuse-derived fuel (RDF) incineration plants for the handling of materials such as wood chips, shredded plastic or tires, paper and cardboard scraps, pellets and/or fluff. Mainly used in cement, paper and industrial plants (high heat-value areas). Technical design Optimisation of crane load capacity thanks to its lightweight design which can hold maximum loads Both motor grab systems (MZG and MMGM) can be made fully automatic by attaching sensors MZG is ideal for use in tight spaces Lightweight design for high load capacity Size, measurements and grab suspension can be customised according to your needs Further advantages: see type MZG port and type MMGM (under “products/motor grab systems) Grab drive Vertical electrohydraulic drive unit with high-pressure pump Turn control or valve control

Request for a quote

KARDEX DEUTSCHLAND GMBH

Germany

The Shuttle XP vertical storage lift system from Kardex Remstar is a highly flexible solution for managing a number of storage and retrieval applications in a wide range of industries.

KARDEX DEUTSCHLAND GMBH

Germany

Kardex Remstar introduces a new control generation to complement all Kardex Remstar automated storage and retrieval systems. This machine based control center brings major improvements in ergonomics and usability of Kardex Remstar automated storage and retrieval systems. It provides a simple, intuitive touchscreen user interface and a basic space management and reporting environment for the Shuttle XP and Megamat RS automated storage systems, with a new state-of-the-art design optimized for both touch and keyboard usage. For customers not requiring a WMS system, the Logicontrol provides an alternative machine based control solution, which means: No additional hardware required, no PC workstation required No loss of data and investment if upgrading to a PC based soft ware solution at a later stage

PRECISION SURFACING SOLUTIONS GMBH & CO. KG

Germany

New standards in CNC tool grinding The ISOG 22 complies with all requirements of the EU Machinery Directive. The maximum tool length for automatic machining has grown significantly – to over 300 mm, whereas previously it was a maximum of 180 mm HIGHLIGHTS OF ISOG 22 Vertical system The special feature of the ISOG 22: It works according to the patented vertical system, and its tool spindle is perpendicular. This means: The tool is optimally accessible from all sides. Its repeatability in the μ range is also incomparable. The extremely high flexibility also benefits from this machine concept. Stable and compact A solid base is the stable cast mineral machine stand made of polymer concrete. With its large mass, it ensures good damping. Highest radius accuracy The very small distance from the grinding point to the pivot point of the C-axis guarantees the highest radius accuracy.

Request for a quote

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Gentle transport of products and high performance due to continuous chain run • Intermediate buffering of several products possible • Up and down movement with same side or opposite side infeed/outfeed Vertical lifts make material flow across several levels possible and are used wherever goods need to be transported vertically - they are ideal for the vertical transport of boxes, trays, plastic containers, bundles, pallets, and bags within automatic conveyor systems. Vertical Lift SPF1S: Transport direction in “S” form. Outfeed side always opposite the infeed side. Vertical Lift SPF1C: Transport direction in “C” form. Outfeed side always on the infeed side.

Results for

Vertical systems - Import exportNumber of results

27 ProductsCountries

- Germany (27)

- Bonn, Düsseldorf and North Rhine and Westphalia (4)

- Frankfurt am Main and Hesse (2)

- Hamburg and region (1)

- Hannover and Lower Saxony (1)

- Kiel and Schleswig-Holstein (1)

- Mainz and Rheinland-Pfalz (1)

- Munich, Nuremberg and Bavaria (3)

- Potsdam and Brandenburg (6)

- Stuttgart, Freiburg and Baden-Wurtemberg (8)

Company type

Category

- Food industry - machinery and equipment (4)

- Lighting, street, industrial and commercial (2)

- Mixers and grinders for the food processing industry (1)

- Packing and packaging - machinery and equipment (1)

- Adjustment - machine tools (1)

- Automation - systems and equipment (1)

- Bottling and filling - machinery and equipment (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Conveyor belts (1)

- Heating, domestic - installations and equipment (1)

- Hydraulic equipment (1)

- Magnets (1)

- Mechanical transmission systems and components (1)

- Optical measuring equipment (1)

- Palletising machinery (1)

- Sawing machine tools (1)

- Storage equipment and systems (1)