- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precision

Results for

Precision - Import export

IDG-DICHTUNGSTECHNIK GMBH

Germany

ORing in material NBR, FKM, FFKM, VMQ, EPDM, ect.

Request for a quote

ASPINA GMBH

Germany

Shinano Kenshi is one of the world's leading OEM manufacturers of stepper motors, servo motors, brushless DC motors and custom motors.

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

The C 62 is a highly dynamic machining centre designed for 5-axis/5-side machining. Numerous features ensure high-precision and cost-effective working on workpieces up to 2500 kg in weight. Various optional extras simply add to the capabilities for innovative advanced machining. As with all HERMLE machining centres, the C 62 offers various workpiece loading options to guarantee optimum operation. Depending on the respective requirements, various additional tool magazines are available. The concept and modular design of the C 62 means individual needs can be met in many different ways. The optimised footprint is another bonus besides the highest standards of quality, precision and accuracy which are synonymous with HERMLE. The C 62: a high-performance all-rounder. In short: a new giant. Milling and turning in one clamping. Fully integrated rotary technology.

Request for a quote

MASCHINENFABRIK BERTHOLD HERMLE AG

Germany

5-axis/5-sided machining means the C 42 lends itself to be used in every application area. With traverse paths adapted to the workpiece size and perfectly designed for 5-axis applications, the C 42 is ideal wherever complex, close-tolerance components are required. This includes various applications in the tool and mould making, medical, aerospace, motorsport, machine sectors and other industries: The C 42 machining centre is at home in every area. The space-saving circular tool magazine integrated into the base body of the machine works according to the pick-up principle - thus enabling quick tool changes. In the standard version, the C 42 can hold 42 tools and can be extended to 192 pockets. The control panel can be easily adjusted to the respective user. Milling and turning in one clamping with the C 42 U MT dynamic model. Fully integrated rotary table that does not interfere with demanding milling processes and 5 axes simultaneously.

Request for a quote

MECHASYS GMBH

Germany

Laser welding is a very gentle welding technique, as the heat input takes place in a locally very limited area. In this way, it is possible to reliably connect critical components with one another in a materially bonded manner, without the parts annealing. With laser welding, the two welding partners are joined together with as few gaps as possible in order to then weld them together (e.g. press-fit zones such as EloPin® puzzled at any feed or distance). The background to this is that no additional material is generally used in laser welding. Exception for build-up welding or repair welding of e.g. broken tool parts such as punches or cutting plates or injection molding tools for abrasive plastics with glass fiber filling. Materials - almost all metals: e.g. • non-ferrous metals (Cu, CuSn0.15, CuSn6, CuNiSi, ...), • titanium, • steel, stainless steel (1.4301, 1.4404, ...), • spring steel (1.4310), • electrical steel (M235, M270, NO20, NO30, ...), …

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

With repetition accuracy of up to ± 0.07 mm, the new high accuracy robot can succeed in even the most demanding of tasks. The deviation from circular diameters of ≤ 10 mm is max. 0.09 mm - half as much as with commercial robots. • Position Accuracy: Highest precision regardless of robot position. • Precision machining: The best choice for laser welding and cutting, TIG, and other tasks requiring high accuracy. The best choice for laser welding and cutting, TIG, and other tasks requiring high accuracy. The main technical specifications at a glance: Number of axes: 6 Working Range (P-Point): R 1664 mm Max. payload capacity: 20 kg Positional repeatability: +/- 0,08mm Drive System: AC Servo Motor Drive Power: 7900 W Weight: 355 kg

Request for a quote

NOVEXX SOLUTIONS GMBH

Germany

Whether it is canisters, large containers, drums or pallets, from barrels to aerosols – the new labeling system ALS 209 from NOVEXX Solutions will win you over with its labeling of a wide variety of products and packaging units. The ALS 209 applies labels with a very large width (up to 229 mm or 9 inches) and is extremely precise and reliable, even in harsh environments. Moreover, due to its extreme compactness, the ALS 209 can be used in a very flexible way. And thanks to its optional tandem function, down time when changing the material is a thing of the past. With the ALS 209, NOVEXX Solutions provides a very efficient and at the same time economically profitable labeling system. Whether it is canisters, large containers, drums or pallets, from barrels to aerosols – the new labeling system ALS 209 from NOVEXX Solutions will win you over with its labeling of a wide variety of products and packaging units.

Request for a quote

CEDS DURADRIVE GMBH

Germany

CEDS synchronous motors offer you special advantages: Very high acceleration capacity Light and compact design Efficient in terms of size High efficiency even at low speeds High speed stability Very high speeds can be achieved Reinforced winding insulation for high dielectric strength and the associated better resistance to partial discharge within the winding Quiet running Low reactive power requirement Synchronous operation of several drives even with different loads In most cases, the rotor of a synchronous machine is designed as a permanent magnet rotor and also has a damper cage to ensure smooth, stable operation of the drive. The interaction of the two magnetic fields of the stator and rotor results in a rotary movement. The operating behavior of the synchronous motor is more dynamic than that of the asynchronous machine

Request for a quote

GSW SCHWABE AG

Germany

All rollers hardened and finepolished Multiple backup rollers to prevent deflection Specially suitable to feed highspeed stamping presses Parallel adjustment of upper roller bank with tilting via spindle type lifting devices With optional synchronized drive of pinch and work rollers Drive system via transfer gear box and universaljoint shafts with length compensation and quickrelease coupling Warpresistant stand in modular design to allow extension with catenary rollers, threading system, loop bridge or conveyors for operation as partsstraighteners etc. Hard chromed rollers Polyurethane coated rollers Hydraulic threading systems in different grades Motorized adjustment of upper roller bank with optional jobmemory Central edge guide adjustment via handwheel (optionally motorized) All roll drive Extricable and exchangable roller cartidges for easy maintenance Quickthreading feature for universaljoint shafts Movable base Manual or hydraulic loop bridge Conveyor belts... etc.

Request for a quote

BIZERBA SE & CO. KG

Germany

Designed to be used for reference weight establishment Inside the load receptor there is an aluminum strain gauge load cell which is perfect for the use in dry areas. As a standard fitted with protection IP41, optionally available with IP65. As compared to other precision scale technologies the iL Precision 65F/SP impresses not only by its simple design but also by reaching its weighing accuracy w/o lever work or motorized calibration device.

Request for a quote

GSW SCHWABE AG

Germany

When straightening becomes core competence and strip or parts need to be completely removed of their tension, GSW Precision Straighteners are the answer of choice. They handle up to 2000mm wide and up to 6mm thick materials in strip or plate. Highest stiffness, closest centerdistances and the active driving of all rolls allow for perfect flatness results. Our newest development – the HighPerformance Straighteners, series RMB – answer questions raised thru current material development leading to increasing material strength, lessening thicknesses or the use of sandwich materials Their enormous stiffness, large pinch rolls and closest center distances evenly deliver highest straightening forces. If material surface quality must be fully preserved, the 6high design option is the right choice. Here, intermittent rolls prevent marking caused by the backup rolls and allow for a perfectly clean strip or plate.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

Precision gears since 1969 ! ZWP manufactures large gears, sun wheels, sun pinions and gear rings for planetary gears and many more fields of transmission. We already supply international renowned customers. Precision articles for industrial use. ZWP is one of Germany’s largest independent contract manufacturers for transmission parts and mechanical engineering. Summary of our production: Internal toothed rings Gears Toothed couplings Shaft pinions ..and many more Other types of production on request. We manufacture according to customer drawings. We already supply renowned companies and export worldwide even to the U.S. and S.-A. ZWP has it´s own hardening facility. This saves time and costs in the manufacturing process. References to our customers in the industry on request. ZWP looks forward hearing from you. We speak fluent English.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in machine support.Made by aluminium, machining and doing the sandblasting and natural anodize surface treatment.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC milling, can process a variety of materials,like Aluminum, Brass, copper,steel, Beonze, Steel Stainless .... Working length range:X:1-1066mm, Y:1-600mm,Z:1-600mm

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These precision and small parts are used in printer accessories.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Precision and complex machining.mask the hole and thread and then procedure in anodize.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material and create the desired shape. A wide variety of materials can be used in CNC turning, including:Aluminum, brass, bronze, copper, hardened metals, precious metals, stainless steel, steel alloys,ABS...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

A flow valve is a critical component in various systems where the regulation of fluid flow is necessary. It’s designed to control the rate at which fluid passes through a system, ensuring that the flow matches the requirements of the application.Flow control valves are essential in industrial usage, hydraulic systems, and pneumatic systems. They play a crucial role in regulating the flow of fluids, ensuring optimal performance and efficient operation of machinery and equipment. Control valves can be actuated in various ways, including pneumatically, hydraulically, or with electric motors. Some valves, known as automatic control valves, do not require an external power source and operate solely on fluid pressure.When selecting a flow control valve, it’s important to consider factors such as flow rate and pressure requirements, material compatibility, and environmental conditions.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

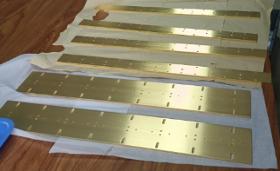

These accessories were made by copper, after CNC machined, then process brushing ,finally do the gold-plating .

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Camera precision aluminum cavity.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining assemblies.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This parts used for mechanical parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Auto accessories parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used for precision machine parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Machine parts processing.

Request for a quote

ROLLON GMBH

Germany

The PRECISION SYSTEM series of linear units are self-sustaining profile systems made of extruded aluminum and steel for the TK series, able to ensure excellent precision. The motion is achieved by means of precision rolled recirculating ball screws with preloaded or non preloaded ball nuts, depending on the models. Using the recirculating ball bearing technology for the screws and the rails ensures great performance to the linear actuators, such as: High precision and high axial forces High mechanical performance Low wear and tear Low resistance to movement High speed (for long pitch screws) The Precision System series consists of 4 distinct products with different features: TH, TT, TV, TK. PRECISION SYSTEM - TH TH linear actuators are rigid and compact, ball screw driven linear units, enabling high positioning accuracy and repeatability in all process phases with optimal performance assured, with a repeatability within 5 µm. Thrust force transmission is achieved by means of...

Request for a quote

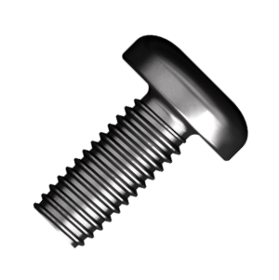

KEBA FASTENINGS

Germany

The Micro Screw range consists of self-tapping and metric standard screws along with metric threads according to customer-specific applications. When the trend is to minimize the size and weight, these durable and small dimensioned screws provide the required competitive advantage where even the smallest gram and millimeter counts. FEATURES & BENEFITS • Diameter range of M 0.8 – M 2.6 • Lengths reaching up to 10x the thread diameter • Capability of various thread heads • Reliability with 50ppm • Thread-forming of even the smallest components for direct assembly • Cost-effective as additional inserts and add-ons are redundant • Time effective as cycle times are minimized in work-flow • Assembly is possible in the smallest of installation spaces • Available in plastic, light metal, and steel materials for use in automated assembly The Micro Screw is available as self-tapping, metric standard as well as customer-specific applications with metric threads.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

These precision pressure regulators can be used in various applications. They convince through their small size, high flow rates and high accuracy. Their modular design allows a cost optimized configuration. High reliability and maintenance free use are ensured for a long lifetime. The pressure setting is done by an adjusting screw. The use of water can be realized with pressure regulator versions without bleeder ports. These pressure regulators are built with a very robust brass housing. Connection is done by 1/8“ NPTF inner thread. On request all pressure regulators can be adapted to different pressure levels or set to a specific output pressure. Seals can be changed from NBR to EPDM or Viton (FKM). Thereby it is easy to adapt the regulators to special media as oxygen (O2) or drinking water (H2O).

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

These precision pressure regulators can be used in various applications. They convince through their small size, high flow rates and high accuracy. Their modular design allows a cost optimized configuration. High reliability and maintenance free use are ensured for a long lifetime. The pressure setting is done by an adjusting screw. The pressure regulator versions with bleeder ports can be used for pressurized air or neutral gases. These pressure regulators are built with a very robust brass housing. The pneumatic connection is done by M5 inner thread. On request all pressure regulators can be adapted to different pressure levels or set to a specific output pressure. Seals can be changed from NBR to EPDM or Viton (FKM). Thereby it is easy to adapt the regulators to special media as oxygen (O2) or drinking water (H2O).

Request for a quoteResults for

Precision - Import exportNumber of results

242 ProductsCountries

- Germany (242)

- Berlin and region (3)

- Bonn, Düsseldorf and North Rhine and Westphalia (46)

- Frankfurt am Main and Hesse (10)

- Hamburg and region (1)

- Hannover and Lower Saxony (18)

- Kiel and Schleswig-Holstein (11)

- Leipzig and Saxony (5)

- Mainz and Rheinland-Pfalz (2)

- Munich, Nuremberg and Bavaria (31)

- Potsdam and Brandenburg (3)

- Saarbrücken and Saarland (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (110)

- Weimar and Thuringia (1)

Company type

Category

- Precision measuring instruments (67)

- Sensors (17)

- Valves for pneumatic equipment (11)

- Calibration equipment (6)

- Machine tools - metal machining (4)

- Mechanical engineering - custom work (4)

- Cutting - machine tools (4)

- Electric motors and parts (4)

- Elements, electric (4)

- Slide production (4)

- Measurement - Equipment & Instruments (3)

- Gears (3)

- Electrical & Electronic Components (3)

- Metal straightening machines (3)

- Machine tools, metal machining - parts and accessories (2)

- Screw cutting - steels and metals (2)

- Forming - steels and metals (2)

- Laser - cutting and welding machines (2)

- Automobiles (2)

- Industrial robots (2)