- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pipe machine

Results for

Pipe machine - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

custom printer accessories for machining.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This is a welded pipe made of stainless steel,mainly used for connect both of the two sides od the products.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

With the new generation of our combination machines, we have continued to develop the new diversity for forming pipes. Geometries that effectively replace high-cost and expensive turned parts can be formed directly at the pipe end in the endforming machine – for a final component of a single workpiece that is ready for use without elaborate soldering or welding. Implementation of the combination can be specified by you or based directly on the forming geometry. This is usually done using up to 6 axial forming stages and at least one rotary unit. Trimming, as well as axial and rotary forming, may require 2 rotary forming stations. Simple trimming or deburring after forming at the pipe end are no demanding challenges. Therefore, all our axial forming machines and combination machines are equipped with one or several single-drive axes. They have a servo-electrical drive and can be used in each of the holders for the forming stages, making the system is very flexible and compact.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

T BEND SERVO-HYDRAULIC Stable, flexible and economical. Our DB 3A-CNC series will win you over with its special stability and performance. A real power pack of a machine For pipes with diameters from 1/4" to 12 3/4". Innovative Servo-Hydraulic System - Energy savings up to 70% by control of the hydraulic pump via a servo motor. On demand system only runs when hydraulic pressure is required; reducing the overall duty cycle and increasing lifecycle of all hydraulic components. The DB 3A-CNC mandrel bending machine performs tight radius bends with the highest quality. The machine meets all industry standards and exceeds customer expectations. The Software – Simple and intuitive manual input by machine operator with 3D graphical display. Import module allows easy import of step files from Tekla and other detailing systems.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Potentiometric displacement sensors are used for direct, precise measurement of mechanical displacements. The mechanical parts of the measuring equipment must be set-up in such a way that the sliding shaft can move without play or lateral forces. A special multi-finger slider ensures good contact even when the adjustment speed is high or in the presence of vibration. With its housing diameter of only 12.7 mm, the model 8709 is also suitable for highly compact structures. The movable fastening clamps allow the user variable options for attaching the sensor without complication. Optionally available adaptations, such as flange and ball joint versions, extend and complement the range of possible applications. Typical fields of application include: Measuring the stroke on riveting machines Measuring insertion distances Offset measurements on bearings Spring travel measurements on axes Measurements of the movement of hoisting platforms Length measurements on pipe bending machines

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

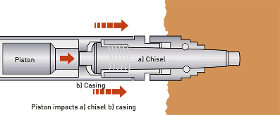

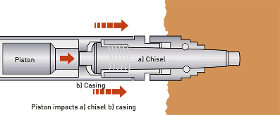

UNDERCROSSINGS Road crossings and property service connections are everyday tasks for the GRUNDOMATN hammer. PIPE RAMMING FROM MODEL 130 GRUNDOMAT Ncan also be used for ramming in steel pipes by attaching a special ram cone to the head of the machine. PIPE BURSTING FROM MODEL95 Modified soil displacement hammers are also applicable for pipe renewal using the pipe bursting method. PILING Grundomats are also ideal for vertical use, e.g. piling for laying foundations.

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

UNDERCROSSINGS Road crossings and property service connections are everyday tasks for the GRUNDOMATN hammer. PIPE RAMMING FROM MODEL 130 GRUNDOMAT Ncan also be used for ramming in steel pipes by attaching a special ram cone to the head of the machine. PIPE BURSTING FROM MODEL95 Modified soil displacement hammers are also applicable for pipe renewal using the pipe bursting method. PILING Grundomats are also ideal for vertical use, e.g. piling for laying foundations.

Request for a quote

ZINSER GMBH

Germany

ZINSER GmbH offers advanced pipe cutting technology known for its precision and efficiency. Our systems are ideal for cutting cylindrical and polygonal pipes made of mild steel, stainless steel and aluminum. With the latest technology and high-quality materials, our machines ensure the highest cutting quality and reliability for industrial applications. ZINSER 1304 / 1306 These specialized pipe cutting machines offer precise and fast cuts. The ZINSER 1304 and 1306 models are perfect for processing pipes with complex geometries and different materials. They offer excellent results for breakthroughs, recesses and end processing. Advantages of ZINSER pipe cutting machines Highest precision: Exact and repeatable cuts thanks to the latest control technology. Versatility: Suitable for different pipe materials and diameters. Efficiency: Cost-effective cutting solutions thanks to innovative technology and robust construction. Durability

Request for a quote

ECOROLL AG WERKZEUGTECHNIK

Germany

ECOROLL's OMEGA system combines skiving and roller burnishing for machining hydraulic cylinders and cylinder liners. While the OMEGA skiving head cuts the cylinder's inner surface to the exact size and form required, the roller head burnishes it. The simultaneous skiving and burnishing process has almost completely replaced honing as the alternative machining process, since it is much more economic and faster. Thanks to its modular design, customized tools can be configured based on pipe quality and machining length. Sometimes for various reasons, tubes have to be skived and burnished separately or both processes have to be carried out one after the other. Therefore, all SK skiving heads can be delivered also as separate tools. SK skiving heads are then used in conjunction with GZ roller burnishing tools. In the first pass the SK skiving head peels the cylinder, and in the second pass the GZ tool burnishes it smooth.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The hose press S2 is available in various variants, perfectly adapted to your needs: S2 - Standard S2 M H Ecoline - Manual, developed pump S2 M Ecoline - Manual S2 P - Pneumatic S2 A - Automatic S2 DC -different voltages possible The new S2 M Ecoline H helps reduce machine downtimes The S2 M Ecoline crimper from UNIFLEX weighs only 30 kg and is the ideal device for the on-site repair of hydraulic hoses in construction and agricultural machinery. Hose connections up to 1" (for 2-part fittings) or 1 ¼" (for single-part fittings) can be established easily and safely – without the need for lubrication, and protected by a sturdy frame. In high-gear mode, the new two-stage pump of the S2 M Ecoline H line works three times faster than previous models. Thanks to the retractable lever, the compact device takes up only minimum space when stowed away.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Due to their compact, all-round accessible construction, high level of user friendliness, and long service life, the HM4xx set the standard for quality and cost effectiveness. The crimpers‘ particularly large opening stroke and the use of long master dies allow you to crimp all types of fittings and up to 8" industrial hoses.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

Balanced weight and compact engineered design make the S7 perfect for workshops and on-site service up to 2“. The tried and tested greaseless slide bearing technology reduces maintenance and increases the product quality.

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

With its crimp force of 2000 kN / 200 t to 2400 kN / 240 t (depending on the Model) and its crimp range of up to 100 mm, it is designed for crimping hydraulic hose assemblies up to 2" and industrial hose assemblies up to 3". This Service crimper is also available as an ecoline or DC variant. * According to the fitting ** Intermediate dies not required *** only with Control B+ Touch

Request for a quote

ROLEC GEHÄUSE-SYSTEME GMBH

Germany

aluDISC is the first round aluminium enclosure for industrial electronics and electronic components. The unique shape integrates perfectly into industrial machinery and piping systems. Whether fitted to the wall, integrated into a pipe system or a machine body – the round shape always makes a good impression. The lid already has a recess to accommodate membrane keypads or a front plate. A version with a fold-out, transparent lid with ingress protection IP 65 is also available. The snap-on design covers hide the screw channels. The enclosure can be mounted while closed. Practical lid supports are also available. Fastening domes in the bottom and the lid to accommodate e.g. circuit boards or mounting plates are also integrated as standard. Matching cable glands and more can also be supplied by us.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KNAUER ENGINEERING GMBH INDUSTRIEANLAGEN & CO. KG

Germany

The very robust design allows extremely high mechanical and electrical (Heat) loads, which occur in machines with e.g. very short cycle times. Fields of application are e.g.: Table vibration of block making and pipe machines, etc, knock out grates, Vibrating beams. Special Features are: • Centrifugal force from 14 kN to 40 kN • Speed from 1000 RPM to 3000 RPM

Request for a quote

WHITE STEEL GMBH

Germany

DESCRIPTION High stability on high capacity. Can handle multiple product viscosity and types Type of metal used S.S 316 / 304 Certifications ISO 90012015, OHSAS 180012007, ISO 500012011, ISO 450012018 SPECIFICATION HMI and SCADA with touch screen system Mixer tank with raw material vacuum sucking technology Can handle multiple viscosity from high to low Double jacket mixer tank for heating and cooling system with pressure and vacuum technology Product certification transferring pump Flowmeter system Exchangeable blades; multiple blades types and design has been manufactured to conform the product types and textures Piping gel cooker machine; Time and speed can be adjusted up to the product needs Automatic product transfer system can be managed with the PLC screen Buffer tank transferring system; cooked products will be transferred from cooker by a homogenizer sucking system Homogenizer with a compact design; with exchangeable heads (conforming the product type).

Request for a quote

KJELLBERG VERTRIEB GMBH

Germany

The HiFocus 360i neo is one of the most flexible and most powerful high-precision plasma cutting units. Its wide cutting range from 0.5 mm to 80 mm means a considerably higher flexibility. The latest inverter technology allows the highest marking quality and functionionality on the market. The HiFocus 360i neo is ideally suited for steel service centers, steel producers and distributors because it can be combined with 2D or 3D CNC-controlled guiding systems like gas cutting machines, robots and pipe cutting machines. With HiFocus neo the user benefits compared to the competitors from higher speed when cutting and marking electrically conductive materials, ensuring at the same time excellent quality and low process costs. Thanks to optimised technology, the consumables are protected and the plasma cutting process is more efficient.

Request for a quote

KJELLBERG VERTRIEB GMBH

Germany

The HiFocus 280i neo is one of the most flexible and most powerful high-precision plasma cutting units. It covers a cutting range from 0.5 mm to 70 mm. The latest inverter technology allows the highest marking quality and functionality on the market. The HiFocus 280i neo is ideally suited for steel service centers, steel producers and distributors.It can be combined with 2D or 3D cnc-controlled guiding systems like gas cutting machines, robots and pipe cutting machines. With HiFocus neo the user benefits compared to the competitors from higher speed when cutting and marking electrically conductive materials, ensuring at the same time excellent quality and low process costs. Thanks to optimised technology, the consumables are protected and the plasma cutting process is more efficient. The HiFocus 280i neo is available as standard with the Contour Cut Technology for cutting fine inner and outer contours and small holes in mild steel.

Request for a quoteResults for

Pipe machine - Import exportNumber of results

22 ProductsCountries

Company type

Category

- Bending machine tools (4)

- Presses, hydraulic (4)

- Plasma cutting machines (2)

- 3D printers (1)

- Agricultural machines and accessories (1)

- Cleaning, industrial (1)

- Cutting - machine tools (1)

- Food industry - machinery and equipment (1)

- Industrial hardware (1)

- Machine tools - metal shaping (1)

- Polishing - steels and metals (1)

- Sensors (1)