- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drive chains

Results for

Drive chains - Import export

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

Precision Transmission Chains from iwis:Roller chains / Transmission chains

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Gearbox lubrication of heavily loaded, relatively slow-running toothed gearing when grease is used instead of oil due to leaks For heavily loaded and impact-loaded drives Chain lubrication, e.g. of hollow-pin chains in the conveyance and transport sector, for exposure to water and steam and at higher operating temperatures Bearing lubrication of friction and rolling bearings in annealing yards and drying systems, manipulators and robots, cooling-bed and conveyor systems, machines in food packing industry, steam sterilisers etc. Advantages and benefits Excellently suited for corrosive operating conditions with high operating temperatures and high pressure and impact loads Economical due to optimised formula Enables wear reduction, decreasing failure times and enabling long-term lubrication Long-acting, highly adhesive, temperature-stable and waterproof, noise-damping, impact and pressure resistant

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of fast-running drive chains of all designs for open or semi-open operation without a permanent re-lubricating device, such as motorcycle and bicycle chains Lubrication of hoisting chains such as multirow roller chains or stacker truck chains, as well as single or multiple flat-link articulated chains Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Extreme adhesive strength Extreme wear protection through Moₓ-Active additive Very high resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral For best adhesion, clean the surfaces mechanically first and then with OKS 2610/OKS 2611 universal cleaner. Apply OKS 340 with a brush, drip oiler, by immersion or using a suitable automatic lubrication system. Spray on evenly OKS 341 spray. Allow excess to drip off and wait for lubricant to penetrate before resuming operation.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of fast-running drive chains of all designs for open or semi-open operation without a permanent re-lubricating device, such as motorcycle and bicycle chains Lubrication of hoisting chains such as multirow roller chains or stacker truck chains, as well as single or multiple flat-link articulated chains Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Extreme adhesive strength Extreme wear protection through Moₓ-Active additive Very high resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral Also available as spray version OKS 341 For best adhesion, clean the surfaces mechanically first and then with OKS 2610/OKS 2611 universal cleaner. Apply OKS 340 with a brush, drip oiler, by immersion or using a suitable automatic lubrication system. Spray on evenly OKS 341 spray. Allow excess to drip off and wait for lubricant to penetrate before resuming operation.

Request for a quote

KAMAT GMBH & CO. KG

Germany

We have specially developed the KAMAT Gekko 350 in order to clean large steel surfaces, for example ships, or large tanks, rapidly and without building scaffolding. Key technical advantages of the high-pressure surface cleaner are the thought-out combination of natural magnets and chain drive, as well as controllable high-pressure nozzles. The complete high-pressure system is remotely controlled conveniently and safely.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of rolling and friction bearings, joints, linear drives and chains Lubrication of fittings, seals, moulded parts and elements of elastic rubber materials in the hot- and cold-water segment Lubrication of fittings or machines in dairies, breweries, bakeries, slaughterhouses, etc. Advantages and benefits NSF H1 registered Reduces wear Excellent resistance to oxidation and ageing Resistant to hot and cold water, water vapour, watery-alkaline and acidic disinfectants and cleaning agents

Request for a quote

GSW SCHWABE AG

Germany

Safe upending (90°) and rotating (180°) of coils Body design in solid welding construction with reinforced base with no pit or floor anchoring needed Body made of strong steel plates Base with large integrated floor plate and attached box construction to protect drive components Tilting unit with neatly welded half shell attachments and two reinforced coil tables welded at 90 degrees to provide safe material seating Bedding via four pressureresistant and fully enclosed bearings with lifetime lubrication Tilting shaft of highquality ductile steel with fully enclosed bearings Tilting drive via threephase motor and triplex type highstrength chain Rotating drive via welded surfacehardened sprocket, integrated in base Tilting function via initiator with arbitrary adjustable tilting point Electrical conrol in switch box with leftright selector switches and estop

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Highly adhesive lubrication of moving parts, e.g. valve spindles, piston rods, wire cables, drag cables, drive and conveyor chains, hinges and guides, at highly corrosive conditions in food processing technology Temporary corrosion protection of ferrous and non-ferrous metals, in particular in highly corrosive atmospheres, such as industrial atmospheres, outdoor weathering under roofs of semi-finished products and finished products Shipping protection of packed and unpacked machines and machine parts, apparatuses and equipment goods under extreme climatic conditions Advantages and benefits Highly adhesive oil with very good creep and lubrication properties Optimal corrosion protection through high effectiveness of the corrosion protection additive After the solvent has dried, forms a transparent, highly adhesive oil film Contains non-ferrous metal deactivator NSF H1-registered

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Highly adhesive lubrication of moving parts, e.g. valve spindles, piston rods, wire cables, drag cables, drive and conveyor chains, hinges and guides, at highly corrosive conditions in food processing technology Temporary corrosion protection of ferrous and non-ferrous metals, in particular in highly corrosive atmospheres, such as industrial atmospheres, outdoor weathering under roofs of semi-finished products and finished products Shipping protection of packed and unpacked machines and machine parts, apparatuses and equipment goods under extreme climatic conditions Advantages and benefits Highly adhesive oil with very good creep and lubrication properties Optimal corrosion protection through high effectiveness of the corrosion protection additive After the solvent has dried, forms a transparent, highly adhesive oil film Contains non-ferrous metal deactivator NSF H1-registered Also available as spray version OKS 3601

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Driving and conveyor chains of all designs in open or semi-enclosed operation without a re-lubrication device Roller chains such as motorcycle and bicycle chains Stacker truck chains as well as single or multiple flat-link articulated chains without a re-lubrication device Rope drives and wire pulls; for example, standing, hoisting, traction or winch ropes in hoisting gears, elevators, lifts or mountain railways Flexible drives, bowden and spring cables Moving machine parts exposed to outdoor weathering, such as toothed gearing, guides, closing mechanisms, hinges or sliding surfaces Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Highly adhesive and resistant to throwing off Contains Moₓ-Active for increased performance Excellent wear protection Very good resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Driving and conveyor chains of all designs in open or semi-enclosed operation without a re-lubrication device Roller chains such as motorcycle and bicycle chains Stacker truck chains as well as single or multiple flat-link articulated chains without a re-lubrication device Rope drives and wire pulls; for example, standing, hoisting, traction or winch ropes in hoisting gears, elevators, lifts or mountain railways Flexible drives, bowden and spring cables Moving machine parts exposed to outdoor weathering, such as toothed gearing, guides, closing mechanisms, hinges or sliding surfaces Advantages and benefits Highly effective due to outstanding creep and gap penetration properties Highly adhesive and resistant to throwing off Contains Moₓ-Active for increased performance Excellent wear protection Very good resistance to cold and hot water as well as to saline solutions Excellent corrosion protection O-ring neutral Also available as spray version OKS 451

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

WRW/SRW – Double column Double column wall mounted stand mixer/floor stand mixer Rigid stand for wall-mounting or floor stand for mixers from 100 kg. The stand consists of 2 u-shaped columns with a ball-borne support slide with a cantilever beam for the mixer. The double-column stand allows the processing of tank volumes up to 4 m3, depending on the tank dimensions. Mixer powers up to 75.0 kW and support loads up to 1,000 kg can be realized. Under these conditions, the stand can be equipped with all fast running or gear-reduced mixers and their matching agitator elements. The lift is done electrically by a lift drive and chain drive. The electric supply is guided through a laterally mounted energy chain. Customized solutions for instance a stand mixer with H foot or stand equipped with coaxial agitator type KRK are feasible.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

WRW - Wall mounted stand mixer Rigid stand for wall-mounting for tank volumes from 100 l. Mixer powers from 0.37 kW to 7.5 kW and support loads up to 100 kg can be realized. Under these conditions, the stand can be equipped with all fast running or gear-reduced mixers and their matching agitator elements. The lift is done by a geared hand-wheel or electric with a lift drive and chain drive. The mixer is positioned on a cantilever beam which is fixed to a support slide that is moved on the stand column. The electric or pneumatic supply is guided through a laterally mounted energy chain. The stand WRW is available in two standard sizes, thus enabling the processing of various tank sizes. The standard sizes are particularly designed for the processing of exchangeable vessels such as drums and IBCs.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

FRW - Mobile stand mixer Mobile stand with H-foot for tank volumes from 100 l. The mobility of the tripod is ensured by using castors and fixed castors. The tripod can be moved due to The lift is done by a geared hand-wheel or electric with a lift drive and chain drive. Mixer powers from 0.37 kW to 7.5 kW and support loads up to 100 kg can be realized (with ex-protection only realizable to a limited extend). Under these conditions, the stand can be equipped with all fast running or gear-reduced mixers and their matching mixing elements. The mixer is positioned on a cantilever beam which is fixed to a support slide that is moved on the stand column. The FRW is equipped with fixed and steerable wheels for mobility. The electric or pneumatic supply is guided through a laterally mounted energy chain. The mobile stand mixer FRW is available in two standard sizes that are particularly designed for the processing of exchangeable vessels such as drums and IBCs. Various tank sizes upon...

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

SRW - Floor stand mixer Rigid stand with H-foot for tanks that range in volume from 100 l. Under these conditions, the stand can be equipped with all fast running or gear-reduced mixers and their matching mixing elements. Mixer powers from 0.37 kW to 7.5 kW and support loads up to 100 kg - by means of a reinforced stand loads up to 300 kg - can be realized. The agitator is positioned on a telescope sleeve that is moved via the spring-suspended lid connected to the stand. The lift is done by a geared hand-wheel or electric with a lift drive and chain drive. The mixer is positioned on a cantilever beam which is fixed to a support slide that is moved on the stand column. The electric or pneumatic supply is guided through a laterally mounted energy chain. The floor stand mixer SRW is available in two standard sizes that are particularly designed for the processing of exchangeable vessels such as drums and IBCs. Various tank sizes upon request.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Double column wall mounted stand mixer/floor stand mixer Rigid stand for wall-mounting or floor stand for mixers from 100 kg. The stand consists of 2 u-shaped columns with a ball-borne support slide with a cantilever beam for the mixer. The double-column stand allows the processing of tank volumes up to 4 m3, depending on the tank dimensions. Mixer powers up to 75.0 kW and support loads up to 1,000 kg can be realized. Under these conditions, the stand can be equipped with all fast running or gear-reduced mixers and their matching agitator elements. The lift is done electrically by a lift drive and chain drive. The electric supply is guided through a laterally mounted energy chain. Customized solutions for instance a stand mixer with H foot or stand equipped with coaxial agitator type KRK are feasible.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Rigid stand for wall-mounting for tank volumes from 100 l. Mixer powers from 0.37 kW to 7.5 kW and support loads up to 100 kg can be realized. Under these conditions, the stand can be equipped with all fast running or gear-reduced mixers and their matching agitator elements. The lift is done by a geared hand-wheel or electric with a lift drive and chain drive. The mixer is positioned on a cantilever beam which is fixed to a support slide that is moved on the stand column. The electric or pneumatic supply is guided through a laterally mounted energy chain. The stand WRW is available in two standard sizes, thus enabling the processing of various tank sizes. The standard sizes are particularly designed for the processing of exchangeable vessels such as drums and IBCs.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GEPPERT RÜHRTECHNIK GMBH

Germany

Rigid stand with H-foot for tanks that range in volume from 100 l. Under these conditions, the stand can be equipped with all fast running or gear-reduced mixers and their matching mixing elements. Mixer powers from 0.37 kW to 7.5 kW and support loads up to 100 kg – by means of a reinforced stand loads up to 300 kg – can be realized. The agitator is positioned on a telescope sleeve that is moved via the spring-suspended lid connected to the stand. The lift is done by a geared hand-wheel or electric with a lift drive and chain drive. The mixer is positioned on a cantilever beam which is fixed to a support slide that is moved on the stand column. The electric or pneumatic supply is guided through a laterally mounted energy chain. The floor stand mixer SRW is available in two standard sizes that are particularly designed for the processing of exchangeable vessels such as drums and IBCs. Various tank sizes upon request.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

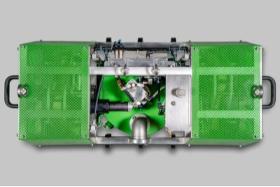

The BaCo 2500 Variospeed is a fully automated filling, foil application and sealing machine, suitable for creamy to liquid filling media for plastic, tin or glass containers. Available performance versions: 2.500 units/h, 3.000 units/h or 3.500 units/h. all gearboxes are maintenance-free: Lenze main drive, Atek gearbox, Miksch stepping gear various cams on drive shafts of the gearbox: filling cam, control cam for valves, pre-sealing cam, lever arm for driving the metering pump and dispenser drive shafts with prockets for chain drives central lubricating system 8-up turntable with mechanical overload clutch backlog detector and monitor for incoming and outgoing containers filling unit with turntable metering unit 40 liters filling funnel dispenser with pre-sealing thermal sealing unit (conductive) integrated conveyor belt central, stepless height adjustment of conveyors and guides by a handwheel integrated SPS control system Siemens S7

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Maintenance free, dry, dust deflecting High temperature resistant Wear protection for metal running faces and rails with minimized friction loss and impressive increased life time of application Highly efficient, reduction of noise and environmental impact Main application Cranes Conveyor systems Guiding rollers Pressure rollers at rotary kilns Dryers Mills Rope drives Chain drives Locomotive wheels Carousel shelf systems

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

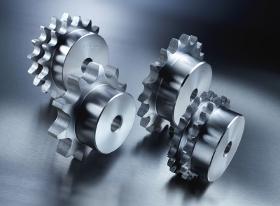

In an industrial facility,motors and turbines use energy to produce rotational mechanical motion.In order to realize this motion, are needed power transmission products to transmit it to other components and machines. Chain drives consist of an endless series of chain links,which mesh with toothed sprockets. Are used to perform three basic functions:transmitting power,conveying materials and timing purposes. Chain drives transfer speed and torque through the use of a linked chain and sprockets. KFB Clarfeld offer chains and sprockets produced according to ISO or ANSI norms.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer aluminium system has stood the test of time for transporting general cargo and bulk goods across long distances. The design allows for non-cutting and fast installation. Common mat chains and drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. Supports, railing brackets, sensors, etc. can be positioned and affixed to the profile as desired with slot nuts. Technical data: —Conveyor body material: Aluminium/stainless steel —Chain width: up to 1400 mm —Conveying speed: up to 80 m/min Optional equipment: —Centre drive + automatic tensioning —Retracting end —Hinged nose —Moving deflecting pulleys —Product guides, fixed or adjustable, design depending on product —Supports to stabilise the conveyor systems at the desired conveying height —Other accessories, such as sensors, stoppers, etc.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer serpentine conveyor has stood the test of time for transporting general cargo vertically. The open construction prevents dirt deposits. Common hinged belt chains and drive engines are used. The chain is optionally equipped with rubberised elements so that large gradient angles can be overcome. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. By connecting a serpentine conveyor that conveys upward and one that conveys downward, the machine can be used as a storage system. Technical data —Conveyor body material: stainless steel —Gradient angle: up to 6° —Chain widths: 82.5 mm, 114.3 mm, 190.5 mm —Conveying speed: up to 50 m/min —Product weight: up to 5 kg Optional equipment —Moving deflecting pulleys —Product guides,design depending on product —Supports to stabilize the conveyor systems at the desired conveying height —accessories: sensors, stoppers, etc.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer stainless steel hygiene system has stood the test of time for transporting general cargo and bulk goods across long distances. The open construction prevents dirt deposits and is suitable for conveying food without packaging. Common mat chains and drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. Technical data: —Conveyor body material: stainless steel —Chain width: up to 1400 mm —Conveying speed: up to 80 m/min Optional equipment: —Centre drive+ automatic tensioning station —Retracting end —Hinged nose —Chain washing station —Moving deflecting pulleys —Product guides, fixed or adjustable, design depending on product —Supports to stabilise the conveyor systems at the desired conveying height —Other accessories, such as sensors, stoppers, etc.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer aluminium compact system has stood the test of time for transporting small products in very tight spaces. The design allows for a mostly non-cutting and fast installation. Common hinged belt chains and drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. Supports, railing brackets, sensors, etc. can be positioned and affixed to the profile as desired with slot nuts. Technical data: —Conveyor body material: Aluminium/stainless steel —Conveyor body width: 90 mm —Chain width: 82.5 mm —Conveying speed: up to 80 m/min Optional equipment: —Moving deflecting pulleys —Product guides, design depending on product —Supports to stabilize the conveyor systems at the desired conveying height —Other accessories, such as sensors, stoppers, etc.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer aluminium system has stood the test of time for transporting general cargo across long distances. The design allows for non-cutting and fast installation. Common hinged belt chains and drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. Supports, railing brackets, sensors, etc. can be positioned and affixed to the profile as desired with slot nuts. Technical data: —Conveyor body material: Aluminium/stainless steel —Conveyor body width: 90 mm —Chain width: 82.5 mm —Conveying speed: up to 80 m/min Optional equipment: —Moving deflecting pulleys —Product guides, fixed or adjustable, design depending on product —Supports to stabilize the conveyor systems at the desired conveying height —Other accessories, such as sensors, stoppers, etc.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer stainless steel hygienic system has stood the test of time for transporting general cargo across long distances. The open construction prevents dirt deposits. Common hinged belt chains and drive engines are used. Here your requests can be taken into account. The drives are delivered as slip-on gears or with chain drive. The modular construction allows them to be re-used later for a new conveyor path. Technical data —Conveyor body material: stainless steel —Conveyor body width: 106 mm, 131 mm, 206 mm —Chain width: 82.5 mm, 114.3 mm, 190.5 mm —Conveyor speed: up to 80 m/min Optional equipment —Moving deflecting pulleys in the curves to reduce wear on chains and slide rails —Product guides, fixed or adjustable, design depending on product —Supports to stabilize the conveyor systems at the desired conveying height —Other accessories, such as sensors, stoppers, etc.

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

Highlights- All-round protection of functional components of the chain: attachments enclose the chain on three sides, even in the vicinity of the chain wheels • Gentle handling of delicate goods • Close-fitting covers prevent the risk of injuries and malfunctions • Outside of the chain is absolutely clean, so no accumulation of dust • Low level of friction in the event of intentional or accidental stoppage of goods conveyed • Drive chain remains clean, even under adverse operating conditions • Suitable for horizontal and vertical running • No lifting of the load in the vicinity of the chain wheels • Various drive chains available e.g. nickel-plated, maintenance-free or corrosion-proof • Different initial lubricant possibilities, depending on individual application

Request for a quote

IWIS ANTRIEBSSYSTEME GMBH & CO. KG

Germany

iwis not only manufactures sprockets and plate wheels according to ISO 606 but also customized versions built in accordance with your specifications, drawings or samples. Sprockets Our standard range of sprockets includes sprockets according to ISO 606 from size 05B-1 to 32B-3. Sprockets with taper-lock bushes Taperlock-bushes for fixing hubs precisely and axially centered on a shaft. Plate wheels Standard plate wheels for the complete iwis product program: sizes 05B-1 to 32B-3. Drive sprockets and idler wheels For the FLEXON Flat Top Chain program. Our drive components program consists of torque limiters, Couplings, Tensioners, Chain tools and etc.

Request for a quoteResults for

Drive chains - Import exportNumber of results

36 ProductsCountries

Company type

Category

- Silicones (8)

- Transportation chains (7)

- Conveyor belts (6)

- Chemical and pharmaceutical industry - machinery and equipment (4)

- Mechanical transmission systems and components (3)

- Crate packing machinery (1)

- Driveshafts and micro-motors - electric (1)

- Handling - Machines & Equipment (1)

- High-pressure cleaning machines (1)

- Industrial sprayers for surface treatment (1)

- Metal straightening machines (1)

- Package stamping machinery (1)

- Storage equipment and systems (1)