- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting process

Results for

Cutting process - Import export

EWS WEIGELE GMBH & CO. KG

Germany

High-speed thread cutting with reversing kinematics The new EWS Tapmatic thread cutting head for driven tools enables thread cutting processes without having to reverse the direction of rotation thanks to its reversing kinematics. This saves time and energy and protects the motor – all this with a defined depth of thread. The units are available for M3-M12 threads.

Request for a quote

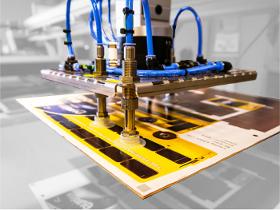

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

BIZERBA SE & CO. KG

Germany

Compact commercial meat mincer for sales counter and preparation area The Carneoline FW N22/82 commercial meat mincer, minces raw, cooked or smoked meat. Even marbled meat – in hot or cold form – bacon, offal, rind and vegetables can be minced. Food processing facilities will achieve perfect results and the machines can be cleaned quickly and efficiently. This heavy duty meat mincer is one of the favourites amongst butchers globally. The robust and easy clean design are not the only benefits to this fantastic piece of machinery. The Bizerba commercial meat mincers incorporate unique technology with a gentle cutting process due to the unique worm solution. Gently mincing the meat as oppose to forcing and and stretching the product. This is how you get the perfect mince every time. Even though the cutting process is gentle, it can still produce up to 350 kilograms of mince per hour. A completely solid stainless steel constructed commercial meat mincer with seamless welding. No...

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Touching-up damaged points on galvanised surfaces, for example after welding, drilling or cutting processes Priming of ferrous metals when zinc galvanising cannot be carried out. For example, in vehicle and ship repairs, in steel building construction, civil engineering and bridge building, in tank and overhead line construction, on grids, fence and traffic signal posts, exhaust systems, drain gutters Also suitable for spot welding thanks to the good electrical conductivity Advantages and benefits Highly effective due to active, cathodic corrosion protection Versatile use as durable corrosion protection at thermally stressed metal parts Highly economical due to low consumption and self-cleaning spray valve Supplements galvanising and forms a rough adhesive surface for subsequent painting

Request for a quote

J.D. GECK GMBH

Germany

Our competences ,Flexible and toolbased sheet metal processing ,2D laser cutting, punched and folded parts. ,Bent wire parts madetomeasure ,Manual and automated welding. We would be happy to manufacture your preliminary products. More information available at https//www.geck.de

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

One for many purposes: Powerful skinning machine for large and small cuts of beef, veal, pork, turkey, horse and game. The Skinner AMS 533 offers an ideal cutting width for processing large cuts, such as beef topside. Advantages Powerful for the highest yield from the smallest installation area Product-specific optional transport rollers and speciallycoordinated blades provide the highest possible yield Ideal cutting width for powerful skinning of large and small cuts Blade guard in cleaning position Gear brake motor with quick stop Product-specific tension rollers Newly-developed compressed air transport roller cleaning,resulting in consistent skinning results Options: Body lever switch Quick release lock for tool-free blade changes Special rollers Skinning procedure protection Special tension rollers

Request for a quote

PRESSTECK S.P.A.

Germany

Experts for deep-drawn parts made of stainless steel, aluminium and other non-ferrous metals (including brass, copper and nickel silver).from new development to series production: We develop perfect deep-drawn parts. Pressteck is one of the world's leading specialists for deep drawing individual parts on transfer presses and for their further processing into assemblies. In this non-cutting forming process, we produce hollow parts in several stages from a metal strip that can be made of aluminium, stainless steel, copper or brass, among other materials. Deep drawing has decisive advantages over other processes: Material consumption and production costs are lower, and at the same time the strength of the components is higher. We are highly innovative and perfect deep-drawing technology beyond what has been possible so far.

Request for a quote

ZINSER GMBH

Germany

ZINSER GmbH offers an extensive range of accessories to optimize your flame cutting machines. Our accessories are designed to maximize the efficiency and performance of your cutting processes by allowing you to optimally adapt your machines to your specific requirements. Plasma systems Our plasma systems offer precise and fast cutting of metals and are ideal for various applications. With our plasma systems you can achieve clean and precise cuts with minimal material loss. Cutting tables with and without extraction Our cutting tables offer an effective solution for air purification and dust extraction during the cutting process. They are available in different designs to meet the requirements of different cutting applications. Extraction systems Our extraction systems are specially designed for plasma, oxyacetylene and laser cutting. They offer high filtration performance and help improve air quality and reduce maintenance costs.

Request for a quote

ZINSER GMBH

Germany

ZINSER GmbH offers first-class environmental technology solutions to complete your cutting systems. Our extraction and filter systems have been specially developed for applications such as plasma, oxyacetylene and laser cutting and set new standards in filtration performance and productivity. We offer you tailor-made solutions for systematic air purification to maximize the efficiency and safety of your cutting processes. Extraction and filter systems ZINSER extraction systems offer the highest performance and effectiveness. Our filter systems are available in various sizes and can be tailored to your specific requirements. They offer plug-and-go functionality, a closed design, quiet operation and high-performance filter cartridges that ensure improved cleaning efficiency and energy cost savings. ZINSER cutting tables Our cutting tables are the optimal solution for air purification during the cutting process.

Request for a quote

ZINSER GMBH

Germany

ZINSER GmbH offers comprehensive software solutions for flame cutting machines that are known for their user-friendliness and efficiency. Our software is designed to optimize the entire cutting process, from the creation of the CAD drawing to the finished flame-cut part. With the latest technology and practical functions, our software solutions improve the productivity and accuracy in your production. ZINSER MCC 20 The ZINSER MCC 20 is our latest cutting software that offers easy operation and a wide range of functions. With this software you can import DWG and DXF files and choose from over 140 standard figures. The MCC 20 enables automatic nesting, drilling with ZINSER Hole technology, as well as the use of a calculation module and an extensive database.

Request for a quote

EUROLASER GMBH

Germany

The laser cutting machine 3XL-3200 is the “Colossus” in the eurolaser cutting series. Textile processing off the role up to 3,210 mm width and of very large materials with seamless cuts is possible. Flexible software packages enable unlimited processing and forwarding of data from other machine producers.

Request for a quote

EUROLASER GMBH

Germany

Textilies can be cut and engraved on a processing area of 1,800 x 3,200 mm (70.9" x 126"). This CO2 laser machine is one of the largest among the eurolaser cutter series and is available with many optional features. An ideal machine size for all applications requiring plenty of space.

Request for a quote

EUROLASER GMBH

Germany

Wood can be cut and engraved on a processing area of 1,800 x 3,200 mm (70.8" x 126"). This CO2 laser machine is one of the largest among the eurolaser series and is available with many optional features. An ideal machine size for all applications requiring plenty of space.

Request for a quote

EUROLASER GMBH

Germany

An increase in productivity thanks to loading and unloading during the cutting process Workpiece removal during the cutting process at the collecting table possible The material feed is stretching-free Accurate placement of the workpiece through automatic edge control with the Feeding Unit Optional camera recognition system for automated processing Optional marking systems (e. g. Ink Marker) Processing of very large formats by edgeless continuation of cuts possible.

Request for a quote

EUROLASER GMBH

Germany

Optimise your production process by automating the supply of your laser system. With our flexibly configurable and scalable robot systems, your jobs will be done quickly and accurately. Fully automated process operation The table already loaded with the new material will be released through a digital signal. Once the working process on the second table is completed, the change will start fully automatically. The new material is cut automatically while the robot will unload the finished work pieces, parallel to the cutting process and without downtimes.

Request for a quote

EUROLASER GMBH

Germany

Loading and unloading during cutting process - increased system duty Easier accessibility of the pieces produced by moving the material support Increasing efficiency by minimising downtime Easy handling Automatic table shift after cutting process possible System is not encapsulated - Robot assembly possible (24/7 - operation) New material is located on the top shuttle table - thereby no material remaining is falling on the new material. Shuttle Table System automatic (STA) Table shift at the touch of a button Process starts automatically after cutting is finished Time saving by optimised processes Minimising supervision of the laser system Additional manual handling possible Snapping table module in after the shuttle process prevents incorrect handlings Of course, the Shuttle Table System is still available as a mere manual version.

Request for a quote

EUROLASER GMBH

Germany

The laser cutting machine 3XL-3200 is the “Colossus” in the eurolaser cutting series. Textile processing off the role up to 3,210 mm width and of very large materials with seamless cuts is possible. Flexible software packages enable unlimited processing and forwarding of data from other machine producers.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

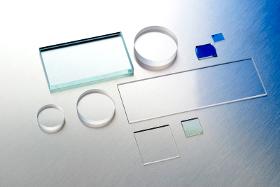

SÜD-OPTIK SCHIRMER GMBH

Germany

Glass and mirror cuts with the most modern cutting and processing options

Request for a quote

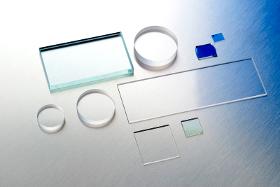

SÜD-OPTIK SCHIRMER GMBH

Germany

Glass and mirror cuts with the most modern cutting and processing options

Request for a quote

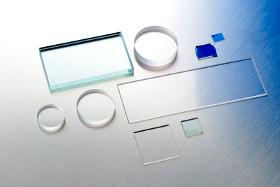

SÜD-OPTIK SCHIRMER GMBH

Germany

Glass and mirror cuts with the most modern cutting and processing options

Request for a quote

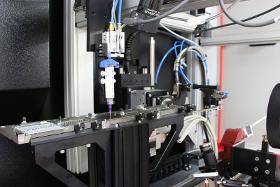

NANOSYSTEC GMBH

Germany

VersaHybrid is a semi or fully automated production system for complex assemblies which require a precision in the low micrometer regime. Assembly techniques include micro welding, selective laser soldering and gluing plus laser fine cutting. Various processing methods are combined in one station. Feeders, belts and robots allow for full automation.

Request for a quote

FRIMO GROUP GMBH

Germany

Ideal for trimming and scoring hidden airbag compartments on thermoformed skin. After the fabrication of IP skins through thermoforming, two separate fabrication steps are still needed before foaming. In the first step, the thermoformed skin will be trimmed in the external zone through punching or a blade cutting process. Depending on the requirements, this is where FRIMO's blade cutting equipment comes into operation. In the second step, the skin will be weakened in the airbag area by a blade. By using the new FRIMO FlexTrim Combi Trim Scoring machine, both steps can be realised at once. The skin is positioned in a common component fixture and finished with two different cutting tools. The new system concept, with its flexible design and layout possibilities, offers a variety of options for combinable process and operation groupings. As an example : one 2-station system with two robots, which are equipped with automatically exchangeable cutter heads, and where two different products

Request for a quote

FRIMO GROUP GMBH

Germany

Ideal for trimming or scoring foils and skins FRIMO's scoring process technology was developed for producing hidden airbags in instrument panels. In contrast to composite component weakening in which the substrate, foam and skin are all weakened in one step, FRIMO prefers material specific single steps. The foil or skin is weakened by blade before foaming. The substrate and foam are separately weakened at the end, which can easily be integrated into the necessary component cutting process. Depending on the customer-specific requirements, this is where FRIMO punching machines or milling machines come into play. Compared to weakening entire composite components (for example, with a laser), a lower investment is required. For the weakening of leather parts for hidden airbags, FRIMO offers a patented process in which the skin is weakened by a rotating circular knife. This process guarantees high precision and odorless results with the shortest possible cycle times.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The Metzner CCM 2 circular cutting machine processes steel-reinforced profiles and sponge rubber materials with dry cutting (optionally with micro-knife moistening to cool the circular knife). The standard model comes with an integrated discharge conveyor (1300 mm length); range of application both in-line and off-line.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner has developed a fully automatic processing machine with outstanding cutting quality and great length accuracy for steel cable wires of up to 20 mm diameter. The steel cable wires are fed by a motorised feeding device in combination with a contact-free loop control. Then, program-controlled and positionally accurate marking tapes are applied to the steel cable – with a cycle time of less than two seconds. In addition, a wax printer marks all the fastening and processing points that will be required for subsequent processing. This labelling method is carried out in a continuous process. The cut is then made using a special cutting process. Precise length accuracy is achieved by a special laser measuring system. A material stacker with a storage area of up to 12 metres ensures that the steel cable wires are deposited in an orderly manner. All cut steel rope can be stored and sorted according to length to allow it to be removed at a later point.

Request for a quote

MESSER CUTTING SYSTEMS GMBH

Germany

You value flexibility? The MultiTherm® is multi-talented thanks to its variety of equipment options to fulfill your current and future application requirements. The MultiTherm® is a versatile cutting machine for plasma cutting, laser cutting, oxyfuel cutting and as well as in combination. The MultiTherm® is versatile and efficient with highest requirements concerning top quality and productivity.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

Extremely durable materials place extreme demands on the knives with which they are processed. Our knives are customized for a wide variety of material mixtures and therefore perform excellently in cold and hot cutting processes.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

Extremely durable materials place extreme demands on the knives with which they are processed. Our knives are customized for a wide variety of material mixtures and therefore perform excellently in cold and hot cutting processes.

Request for a quote

WINTERHOFF PICARD GMBH

Germany

Extremely durable materials place extreme demands on the knives with which they are processed. Our knives are customized for a wide variety of material mixtures and therefore perform excellently in cold and hot cutting processes.

Request for a quoteResults for

Cutting process - Import exportNumber of results

51 ProductsCountries

- Germany (51)

- Bonn, Düsseldorf and North Rhine and Westphalia (12)

- Frankfurt am Main and Hesse (3)

- Hannover and Lower Saxony (8)

- Kiel and Schleswig-Holstein (1)

- Leipzig and Saxony (2)

- Mainz and Rheinland-Pfalz (5)

- Munich, Nuremberg and Bavaria (6)

- Potsdam and Brandenburg (4)

- Stuttgart, Freiburg and Baden-Wurtemberg (8)

- Weimar and Thuringia (2)

Company type

Category

- Laser - cutting and welding machines (8)

- Knives, industrial (7)

- Plasma cutting machines (4)

- Cutting - machine tools (3)

- Lens products (3)

- Cutting, plastics - machinery (2)

- Mechanical engineering - custom work (2)

- Cutting - steels and metals (1)

- Butchery - machinery and equipment (1)

- Engraving, industrial - steels and metals (1)

- Forming - steels and metals (1)

- Import-export - electrical and electronic equipment (1)

- Machine tools, metal machining - parts and accessories (1)

- Meat processing machines (1)

- Mechanical transmission - components (1)

- Milling - machine tools (1)

- Robotics (1)

- Shearing machine tools (1)

- Silicones (1)

- Steel & Metals (1)