- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tool change

Results for

Tool change - Import export

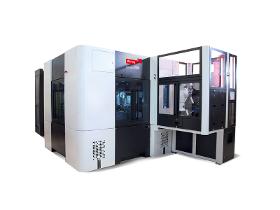

STARRAG GMBH

Germany

With the FOGS NEO series, Droop+Rein has developed a powerful machine concept for complex machining. The range of services covers processes from machining standard geometries and prefinishing contours to final finishing. For dynamic machining with the highest feed rates, the concept caters for the movement and acceleration of constant masses, regardless of workpiece size and weight. Dynamic and flexible With its new, highly flexible and fast Caxis (±400°), the Droop+Rein FOGS NEO highspeed machining centre is ideal for the complete multifunctional machining of very large workpieces. Of course, the series also features automatic pallet or tool change, tool diameter and length measurement and automatic billing of contour deviations. Thanks to a variety of components and peripheral devices from their modular system, Droop+Rein can create an efficient and processoriented overall system that is tailored to the customer.

Request for a quote

STARRAG GMBH

Germany

This highspeed machining center is perfect for rapid cutting of small and mediumsized workpieces with maximum productivity. The critical innovation is the Sprint Z3 parallel kinematic machining head, which enables components to be produced with excellent dynamics and precision and an outstanding surface quality, at batch sizes of a single unit through to bulk production. The excellent machining and surface quality means that there is no need for the manual rework that is usually required with conventional machining centers. This results in increased efficiency, improved process reliability and longterm stability. The key features include 1,000 x 1,000 mm pallet size, up to 120 kW spindle power and rapid tool change, from either a chain or rack magazine.

Request for a quote

STARRAG GMBH

Germany

Flexibility, efficiency and precision play a very important role for machine manufacturers and tool builders, especially when dealing with large components. These three requirements led to the development of the gantry machining centre TS/TFS NEO with a fixed and movable crossbeam, whereby the customer chooses the table designs, controls and milling units suitable for them on a modular basis. The TS/TFS NEO features a new milling unit and a modified Caxis (±400°) which, thanks to its enormous flexibility, can be used for efficient production of highly precise machine parts. The large number of automatically changeable milling heads increases the machine's flexibility within its scope of application. The TFS also allows automatic tool or spindle changing and tool or workpiece measurement.

Request for a quote

STARRAG GMBH

Germany

A standalone monostation machine A compact industrial concept for maximum performance taking up minimum floor space With its dual spindle concept enabling concurrent tool change operations, its high dynamic acceleration, its powered spindles capable of a rotation speed of up to 60.000 min1, its high number of tools, the s100 is a modern production tool pushing back the boundaries of highprecision machining. The s100 range makes it possible to produce highly complex parts. Ideal for 3 axis machining of watch movement parts, it has also proven itself unbeatable in a whole host of fields, such as mobile telephony, electronics or nanotechnologies. Features Unique dual spindle concept Highly dynamic acceleration, up to 3g

Request for a quote

STARRAG GMBH

Germany

A 4station transfer machine A compact industrial concept for maximum performance taking up minimum floor space With its dual spindle concept enabling concurrent tool change operations, its high dynamic acceleration, its powered spindles capable of a rotation speed of up to 60.000 min1, its high number of tools, the s100 is a modern production tool pushing back the boundaries of highprecision machining. The s100 range makes it possible to produce highly complex parts. Ideal for 3 axis machining of watch movement parts, it has also proven itself unbeatable in a whole host of fields, such as mobile telephony, electronics or nanotechnologies. Features Unique dual spindle concept Highly dynamic acceleration, up to 3g 4 machining stations Up to 36 tools integrated into the machine

Request for a quote

STARRAG GMBH

Germany

The Bumotec s1000 C horizontal transfer machine was designed to manufacture prismatic parts from round or profiled bar stock. Small and complex components can be efficiently machined in medium to large batch sizes. The machine is configured with seven 4axis machining stations, each equipped with 4 machining spindles (2 horizontal and 2 vertical). The eight stations comprise a 4axis cut off station with a single spindle. An optional ninth station allows the component to be reclamped to allow the sixth side of the component to be machined with an additional 3axis, 3 or 4 spindle machining unit. The machine is equipped with an automatic bar feed and quick change tool clamping system for optimum production rates. Features 9 machining stations Up to 36 tools integrated into the machine

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Tool change - Import exportNumber of results

6 ProductsCountries

Company type