- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heat transfer systems

Results for

Heat transfer systems - Import export

FRIEDR. FREEK GMBH

Germany

HotMicroCoils have an exceptional capacity for being shaped - even in three dimensions. Many special winding patterns and geometries apart from the purely cylindrical are thus possible, allowing heating close to the contours of all manner of surfaces. Applications include hot runner manifolds, heating plates and hot die stamps. The shaped heating elements thus obtained can be used in two principal ways: either placed over the surface to be heated (firmly bonded by soldering, force-fitted, pressed or otherwise appropriately joined) or pressed into a positive fit in grooves in the surface to be heated. The second of these alternatives is also becoming more widely accepted in plastics processing, as it offers the best heat transfer because the heating area is the greatest (see also Freek Heat Transfer System). Since not all our customers have the necessary equipment and experience to press the HotMicroCoil elements into the contours of the surfaces, Freek also offers this as a service.

Request for a quote

FRIEDR. FREEK GMBH

Germany

The Freek heat transfer nozzle heating system especially addresses manufacturers and users who operated their hotrunner nozzles with cast-in heaters in the past and would like to stick to their engineering know-how without paying the high price of this former heater design. The standard material of our Freek heat transfer nozzle heater alternative is brass, with or without coating, preferably with a slit. The slit allows the assembly of an external bendable thermocouple and facilitates the disassembly, e.g. in case of a revision and can be coiled over. This is not possible at competitor's nozzle heater solutions. Freek's tight coiling at the heater's ends provides a maximum possible power concentration (patented).

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

For its exhaust gas purification systems, Venjakob Umwelttechnik offers heat exchanger systems for utilizing the waste heat. These are characterized by: We build complete heat exchanger systems for heating water, steam, air, and gas or heat transfer fluid. The residual or excess energy contained in the clean gases of the Venjakob exhaust air cleaning systems often has sufficient potential to effectively support the actual production process, the building heater or other energy consumers. Whether as an individual system for heat transfer fluid, warm and hot water, hot air, and vapor, or combined as a downstream system solution for an exhaust air purification system - the planning, construction and production of the plant are done on an individual basis.

Request for a quote

DEKORTECH GMBH

Germany

Digitally printed heat transfers for packaging applications - printed roll to roll. ✔ No MOQ ✔ up to 318mm printing width ✔ Adhere to many materials ✔ High gloss finish ✔ Photo-realistic prints ✔ Fastest shipping Digital heat transfers are the easiest way to get into digital printing for your products. Therefore, we print them on demand with any design you need. With a range of adhesives, these transfers can be produced to stick to PP, ABS, paper, glass, ceramics, varnishes, Tritan and many other materials. Printed in less than 5 days, you will be ready to roll in no time. For the printing itself we use a high-end digital printing press based on toner and combine it with water-based adhesives without UV or VOCs. With this mix we can print details as tiny as 1-point small text. Personalized or serialized prints with safety features are also available. All you need to apply them is a heat transfer or hot stamping machine.

Request for a quote

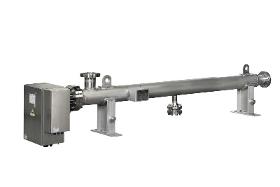

SCHNIEWINDT GMBH & CO. KG

Germany

CSN® explosionproof flow heaters are used for heating up flowing gases and liquids in hazardous areas. The devices consist of explosionproof flanged immersion heaters, which are installed in corresponding pipe or pressure vessel. Our products realize individual solutions for complicated technical process. Different heating systems for heating up liquids, nitrogen or other gases activate exact determinded processes in chemical factories. In close discussion with our customers problems will be defined and changed in technical optimale solutions. Our QualityManagementSystem ensures the high quality level of our customers. Further information about our CSN® Exflow heater

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SANHA GMBH & CO. KG

Germany

Our quality SANHA ball valves are made of brass CW 617N and can be delivered in a multitude of versions such as with threaded and press ends, or in the dimensions 15-54 mm, 16-26 mm and ½" to 2". The ball valves can be easily and quickly combined with all SANHA systems, thus providing a real alternative to conventional products. With SANHA ball-stop valves we provide our customers with the oppurtunity for an optimal safe and at the same time very economical solution for the installation of machinary, equipment or other facilities such as risers.

Request for a quote

BAUSHOP EXPRESS GMBH

Germany

Like the slightly less powerful MA series, it is guaranteed absolutely exhaust-free hot air. In addition, the units can be operated not only with oil, but are also approved for gas operation. The operating mode can be flexibly adapted to the conditions on site. Thus, the devices can be used in all areas. Hot air hose systems can also be connected without any problems thanks to the high-performance radial fans. Consequently, effective heating from outside is also possible without any problems. The recirculation module ensures efficient and economical operation. The oil burner blowers are made of high-quality materials by renowned manufacturers. They work so efficiently that 93% of the energy can be converted into heat.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

nduction Heating and Joining in one turnkey system. This turnkey system is used to heat electric motor housings with various dimensions for a wide range of joining processes. Example Heating System 1: the die-cast aluminium housing for an asynchronous motor (diameter 450 mm) is heated to approx. 290°C in approx. 5 minutes to fit the wound stator package. The parts are loaded and unloaded from the feeding belt parallel to the working time. The heating process takes place in two independent work stations. The generator has a switched output which means that only one generator is required for the two heating stations. The system is controlled using a SIEMENS PLC controller. Example Heating System 2: the aluminium housing (diameter 140 mm) of a synchronous motor is heated to approx. 280°C in approx. 3 minutes to fit the stator. The component is loaded into and unloaded from the heating station semiautomatically. The system is controlled using a PLC.

Request for a quoteResults for

Heat transfer systems - Import exportNumber of results

9 ProductsCountries

Company type