- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hard surfacing

Results for

Hard surfacing - Import export

BORNEMANN GMBH

Germany

For hard castings, we offer manual dies made from sinter metal. Sinter metal dies are characterised by a hardness of 68 to 70 HRC. With these dies, welded or processes hard surfaces can be labelled. Company logos as well as individual numbers and letters can be provided. The maximum font size should not exceed 10 mm.

Request for a quote

BORNEMANN GMBH

Germany

Machine dies made from sinter metal that achieve a hardness of 68 to 70 HRC are a speciality of ours. With these dies, materials with a surface hardness of up to 48 HRC can be labelled. By using a complex production method and a special hardening, special options of use in labelling are achieved for these unique hard dies. The dies are produced to customer drawing or data.

Request for a quote

ROLLON GMBH

Germany

Speedy Rail is the special self-supporting and self-aligning rail in extruded aluminum with a deep hard anodized surface treatment that offers exceptionally high performance and load capacity, with no maintenance and lubrication required, total reliability even in dirty environments with uniquely quiet operation. It is available with v-shaped rollers or cylindrical rollers, both covered in a plastic compound, and can be used as a linear rail or actuator. High reliability up to 80,000 Km Self-supporting for greatest design freedom Self-aligning system Uniquely quiet High technical performance High load capacity of over 3,000 Kg Optimal reliability in dirty environments Absence of lubrication Potentially infinite strokes with jointed versions Ideal for making 2 or 3-axis Cartesian systems for several applications Use as a linear guide or actuator thanks to belt or rack and pinion drives Main fields of application: Self-supporting linear rails for welding machines Self-supporting...

Request for a quote

ROLLON GMBH

Germany

Speedy Rail is the special self-supporting and self-aligning rail in extruded aluminum with a deep hard anodized surface treatment that offers exceptionally high performance and load capacity, with no maintenance and lubrication required, total reliability even in dirty environments with uniquely quiet operation. It is available with v-shaped rollers or cylindrical rollers, both covered in a plastic compound, and can be used as a linear rail or actuator. High reliability up to 80,000 Km Self-supporting for greatest design freedom Self-aligning system Uniquely quiet High technical performance High load capacity of over 3,000 Kg Optimal reliability in dirty environments Absence of lubrication Potentially infinite strokes with jointed versions Ideal for making 2 or 3-axis Cartesian systems for several applications Use as a linear guide or actuator thanks to belt or rack and pinion drives Main fields of application: Self-supporting linear rails for welding machines Self-supporting...

Request for a quote

IGUS® GMBH

Germany

drylin® ZLW-0630 basic toothed belt axis, basic version, feed rate 54mm/rev, aluminium profile, surface: hard-anodised, neoprene toothed belt in black, guide carriage length 60mm, shaft end support made of aluminium, alignment of drive pin on the right, stepper motor with stranded wire. Configure drylin SHT linear modules individually here: https://igus.eu/ddx

Request for a quote

IGUS® GMBH

Germany

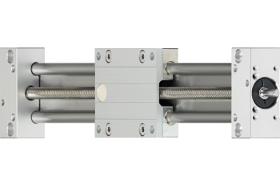

drylin® SAW-1040 linear module, drylin® W aluminium profile, surface: hard-anodised, Trapezoidal lead screw TR10x2, machined lead screw end 69x15mm, guide carriage, aluminium shaft end support. Stroke length: 500mm, carriage length: 69mm, NEMA23 stepper motor with JST connector. Configure drylin SHT linear modules individually here: https://igus.eu/ddx

Request for a quote

IGUS® GMBH

Germany

drylin® SLW-1040 linear module, drylin® W aluminium profile, surface: hard-anodised, ball bearing Trapezoidal lead screw TR10x2 made of stainless steel, lead screw end machined 6h9x17mm, guide carriage in 100mm length, shaft end support made of anodised aluminium. Configure drylin SHT linear modules individually here: https://igus.eu/ddx

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

J73A UP is the next generation of anodized aluminum coil stock for architectural facades and roofing. Well suited for the challenges of modern architecture, this Novelis product arrives already anodized so that it can be used immediately. Take advantage of characteristic brilliance, a long service life due to a high degree of surface hardness, as well as outstanding UV, weather and corrosion resistance.

Request for a quote

SPANSET SECUTEX GMBH

Germany

The SZSSL is a specially developed prongprotection shoe for the highest demands. The robust profile constructed from steel with a steel point is especially designed for hard, prolonged use. Surface structures We offer special surfaces for exceptional applications under the influence of water, oil or ice. Speak with your professional consultant today!

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

The performance and aggressiveness of brown fused alumina type WIWOX® NK produces a strong removal effect as well as a uniformly structured surface. The high TiO₂ content makes it extremely hard and tough, whereby the surface roughness can be greatly changed. Also available as microcorn with a precise grain distribution up to 3 μm.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The 8524 precision tension & compression load cell is a versatile sensor for highly accurate load measurements in diverse applications. Optimum measurement quality is achieved with the load cell mounted on a flat, hard and polished contact surface. This requirement does not apply to small measurement ranges of up to 0 ... 2 kN because three knife-edge bearings ensure that the sensor is seated securely. Our brochure „Load Cells“ explains how you can design parasitic loads out of your mechanical system. Through-holes in the outer flange are used for fastening the 8524 sensor to the system structure. The load is applied via the central blind threaded hole or optionally via a load button. Alternatively, a pull plate and even rod end bearings, if desired, can be attached to the sensor for equally easy measurement of purely tensile loads, for instance in Bowden cables or chains. The 8524 sensor is designed to measure static, quasi-static and dynamic compressive and/or tensile loads.

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

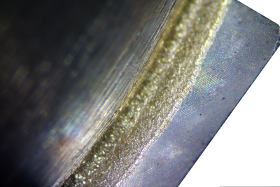

STEEL GRADES The standrard stock of chromed bars consists of steel grades C45 or C45E or C45R and 20MnV6 in untreated delivery condition (+AR) and 42CrMo4 in quenched and temperd delivery condition (+QT). DELIVERY CONDITIONS The solid bars subjected to chroming process are available in different delivery conditions in orde to obtain specific properties. NORMALIZATION Heat treatment consisting heating process followed by gradual cooling in controlled atmosphere. Thanks to this process the steel structure becomes more "refined" and improve its impact properties (perlitic structure). INDUCTION HARDENING The surface of the steel bar is heated by electric induction followed by fast cooling. This process leads to a high surface hardness but also to fragility and low impact values (Martensite surface structure). QUENCHING AND TEMPERING Quenching process followed by tempering. This process leads to a good hardness and resistance and it reduces its fragility in comparsion to induction...

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

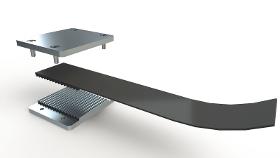

KEIPER timing belt clamping plates can be made of many different materials, e.g. aluminum, steel or stainless steel. Keiper can produce them in all pitches and designed according to your specifications and drawings. This means that you will receive the optimal solution for the intended application and load. Our timing belt clamping plates work together optimally with our extensive and complete range of timing belts: in other words, a perfectly matched system for your requirements. We also have a large number of standard aluminum clamping plates on stock, which can be reworked according to your specifications (e.g. bores and mechanical processing based on drawings). Furthermore, such special surface coatings as hard coating, anodizing, zinc coating or bronzing improve the corrosion and wear resistance.

Request for a quote

WIGTEC FISCHEREDER KG

Germany

In the WTH 200.2, the following materials can be reliably brazed with active materials in a high vacuum. PCD (polycrystalline diamond) MKD (monocrystalline diamond) CVD diamond (chemical vapour deposition) PCBN (cubic boron nitride) and Hard metals as well Ceramics In the high-vacuum furnace WTH 200.2, our customers manufacture indexable inserts, dressing wheels, rotating tools and turning tools with blades made of natural diamond or MKD for polish turning. The vacuum brazing is flux-free. In the so-called active brazing process, titanium allows wetting of the surfaces. While cemented hard metals can also be inductively brazed, diamonds, CVD and ceramics must be actively brazed in a vacuum. When brazing PCD and PCBN, not only the hard metal substrate but also the PCD or PCBN layers are wetted.

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Braid of ePTFE Fiber with Incorporated Graphite and Silicone Run-In Lubricants Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar Characteristics Good heat conductivity Extended lifetime Easy installation and safe handling No ageing process Resistant against Sewage, Boiler Feed Water, Acids, Alkaline solutions, Oil and Grease Cost effective ePTFE/Graphite Packing Recommended shaft surface hardness: HRC 35 Operating range Pressure [p max]: 25 bar, Velocity [v max]: 20 m/s Pressure [p max]: 250 bar, Velocity [v max]: 2 m/s Pressure [p max]: 150 bar Temperature: t = -100… +280 °C pH: 0 - 14 Density: 1.50 g/cm³ Practical useful application data: max. temperature: +200 °C max. pressure centrifugal pumps: 20 bar Main application Centrifugal pumps Mixer Kneader Agitators Autoclave Refiner Vacuum pumps Suitable for Chemical industry Power plant technology Pulp and paper industry Universal use Installation and maintenance...

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

Requirements for products working in a high temperature fusing environment include continuously increasing requests for longer part life, higher print speed, and better print resolution involving ongoing material and process innovations. Our goal is to find the best combination of the following properties: Thermal resistance Thermal conductivity Abrasion resistance Anti-adhesive surfaces Elastomer hardness Substitution of Metal Substrates by Polyimide Belts Fusing by heat and pressure in digital printers has previously been realized with anti-adhesive coatings on aluminum or steel cores. These metal substrates have been increasingly replaced by seamless thin walled polyimide belts due to energy-saving environmental regulations and the growing requirement for “instant on” printing devices. Image Fusing Products Fuser rollers with soft and thin coatings more Fuser rollers for professional digital printing more Pressure rollers with solid silicone/PFA sleeves more Pressure rolle

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Polyimid Fiber with PTFE Impregnation and Silicone Run-In Lubricant Practical useful application data: max. temperature: +180 °C High fatigue strength and flexibility Good acid resistance High cross section density through PTFE blocking agent, good for crystallizing media Recommended shaft surface hardness: HRC 35 Good pliability, therefore perfect adaption of uneven shaft surfaces Operating range Pressure [p max]: 20 bar, Velocity [v max]: 15 m/s Pressure [p max]: 60 bar, Velocity [v max]: 2 m/s Pressure [p max]: 100 bar Temperature: t = -100… +280 °C pH: 0 - 12 Density: 1.30 g/cm³ Practical useful application data: max. temperature: +180 °C Main application Centrifugal pumps Mixer Kneader Agitators Filter Extruder Refiner Suitable for Chemical industry Sugar industry Pulp and paper industry Mining Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and special measurements. 04 - 09 mm on 1 kg spool 10 - 15 mm on...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

100% PTFE - Fiber with special PTFE Dispersion and FDA conform Siliconoil impregnated Characteristics Highest chemical resistance for a packing in rotating equipment Pliable, easily compressible packing Self lubricating, dry running capability Shaft protecting surface hardness of HRC 25 is sufficient Non ageing Operating range Pressure [p max]: 25 bar, Velocity [v max]: 2 m/s Pressure [p max]: 250 bar, Velocity [v max]: 1 m/s Pressure [p max]: 500 bar Temperature: t = -100… +280 °C pH: 0 - 14 Density: 1.70 g/cm³ Main application Agitators Mixer Refiner Filter Slow speed Centrifugal pumps Valves, Gate valves Metering valves Suitable for Pulp and paper industry Chemical industry Pharmaceutical industry Food industry Approvals FDA conformity EN 1935:2004 in accordance with EN 10/2011 Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and special measurements. 04 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg spool 16 -...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

PTFE Fiber with PTFE Blocking Agent and Silicone Free Run-In Lubricant Characteristics Highest chemical resistance for a packing in rotating equipment Pliable, easily compressible packing Self lubricating, dry running capability Shaft protecting surface hardness of HRC 25 is sufficient Non ageing Operating range Pressure [p max]: 15 bar, Velocity [v max]: 10 m/s Pressure [p max]: 100 bar, Velocity [v max]: 1.5 m/s Pressure [p max]: 100 bar Temperature: t = -50… +280 °C pH: 0 - 14 Density: 1.70 g/cm³ Main application Agitators Mixer Refiner Filter Slow speed Centrifugal pumps Valves, Gate valves Metering valves Suitable for Chemical industry General industry Variant S6SI with Food certification EG 1935:2004 in accordance with EU 10/2011 FDA conformity Form of delivery This packing can be manufactured from 3 to 40 mm square as well as in intermediate, inch sizes and special measurements. 03 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg spool 16 - 25 mm on 5 kg spool Special...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

High strength ePTFE-Graphite Characteristics Extrusion resistant even with large clearances Form stable, wear resistant, heat conductive and can be used as bull ring Shaft protecting (recommended surface hardness: HRC 25) In high pressure applications die formed rings are recommended Operating range Pressure [p max]: 30 bar, Velocity [v max]: 8 m/s Pressure [p max]: 800 bar, Velocity [v max]: 3 m/s Pressure [p max]: 500 bar Temperature: t = -200… +280 °C pH: 0 - 14 Density: 1.35 g/cm³ Main application High pressure plunger- and dosing pumps Bullrings for mixers, highpressure valves agitators, gate valves and valves Suitable for Chemical industry Petrochemical plants High pressure machine constructions Approvals BAM for liquid and gaseous oxygen 60 °C/15 bar, 40 °C/65 bar, 200 °C/50 bar Form of delivery This packing can be manufactured from 3 to 40 mm square as well as in intermediate, inch sizes and special measurements. 03 - 09 mm on 1 kg spool 10 - 15 mm on 2,5 kg...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Combination braid from Carbon reinforced expanded Graphite Tape and Carbon Fiber Practical useful application data: max. temperature: +250 °C Characteristics High standardisation potential Wear resistant through running track reinforcement, nevertheless shaft protecting Recommended shaft surface hardness: HRC 45 Excellent heat conductivity, suitable for dry running applications Non-hardening, good reset capability, coefficient of thermal expansion like steel Self lubricating excellent use in pumps, minimising the need of Flushwater Operating range Pressure [p max]: 25 bar, Velocity [v max]: 30 m/s Pressure [p max]: 100 bar, Velocity [v max]: 2 m/s Pressure [p max]: 100 bar Temperature: t = -50… +300 °C pH: 2 - 12 Density: 1.00 g/cm³ Practical useful application data: max. temperature: +250 °C Main application Centrifugal pumps Boiler feed water pumps Mixer Agitators Refiner Kneader Suitable for Power plant technology Boiler houses Pulp and paper industry Chemical and...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Hybrid-Braid in W-Profile of heat conductive ePTFE Yarn with Silicon oil run in lubricant lubricant and form stable PTFE fibers Practical useful application data: max. temperature: +200 °C max. velocity centrifugal pumps: 16 m/s Characteristics Wear resistant through Running Track Reinforcement Very high heat conductivity through employment of a special heat conductive Compound Clean packing, no contamination of medium Increases the operative lifetime due to high mechanical strength and excellent heat conductivity Provides maximum protection of shaft against wear Recommended shaft surface hardness: HRC 25 Operating range Pressure [p max]: 20 bar, Velocity [v max]: 20 m/s Pressure [p max]: 100 bar, Velocity [v max]: 2 m/s Pressure [p max]: 100 bar Temperature: t = -100… +280 °C pH: 1 - 14 Density: 1.80 g/cm³ Practical useful application data: max. temperature: +200 °C max. velocity centrifugal pumps: 16 m/s Main application Centrifugal...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Combination braid of ePTFE Yarn incorporated with Graphite, Meta-Aramid Fibers and special impregnation Practical useful application data: max. temperature: +200 °C Characteristics Excellent Standardisation possibilities High Cross Sectional density, yet still elastic and flexible Suitable for use with hardening and crystallizing products Displays reduced wear through special running track reinforcement Unique formulation impregnation improves flexibility, ensures packing will not harden Provides excellent chemical resistance Recommended shaft surface hardness: HRC 35 Operating range Pressure [p max]: 25 bar, Velocity [v max]: 20 m/s Pressure [p max]: 150 bar, Velocity [v max]: 2 m/s Pressure [p max]: 150 bar Temperature: t = -100… +280 °C pH: 1 - 13 Density: 1.50 g/cm³ Practical useful application data: max. temperature: +200 °C Main application Centrifugal pumps Mixer Agitators Fittings Filter Suitable for Pulp and paper industry Chemical industry Form of delivery This...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

High purity Carbon Fiber with cross section impregnation and run in lubricant Practical useful application data: max. temperature: +250 °C Characteristics Excellent Standardisation features Cross section impregnation avoids the penetration of crystallizing mediums Wear resistant against abrasive products and with minimal coefficient of friction Self lubricating fiber with high Carbon content, reduced shaft wear and excellent heat transfer characteristics Thermally balanced construction, the coefficient of expansion is similar to steel, the packing is volume stabile and does not shrink. Therefore minimal re-adjustment needed after installation. Excellent chemical resistance Recommended shaft surface hardness: HRC 45 Operating range Pressure [p max]: 30 bar, Velocity [v max]: 25 m/s Pressure [p max]: 100 bar, Velocity [v max]: 2 m/s Pressure [p max]: 100 bar Temperature: t = -50… +300 °C pH: 2 - 12 Density: 1.45 g/cm³ Practical useful application data: max. temperature: +250...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Combination Braid of ePTFE with incorporated Graphite and Para-Aramid Fiber Corner Reinforcement with Special Blocking compound Practical useful application data: max. temperature: +200 °C Characteristics Reinforced packing with reduced wear through improvedheat conductivity Recommended shaft surface hardness: HRC 50 Safe universal packing for abrasive media Extrusion resistant, ideal for worn equipment with bigger gap width Development: Better sealability of stuffing box Operating range Pressure [p max]: 25 bar, Velocity [v max]: 20 m/s Pressure [p max]: 500 bar, Velocity [v max]: 3 m/s Pressure [p max]: 250 bar Temperature: t = -100… +280 °C pH: 2 - 12 Density: 1.50 g/cm³ Practical useful application data: max. temperature: +200 °C Main application Centrifugal pumps Mixer Agitators Autoclave Filter Refiner Kneader Paddle dryer Suitable for Pulp and paper industry Sugar industry Waste water technology Chemical industry Variant Square shape S12K Plunger with ParaAramid-Corner...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Para-Aramid Fiber Packing with PTFE Impregnation and Run-In Lubricant Practical useful application data: max. temperature: +200 °C Characteristics Volume stable, pressure stable High cross section density through PTFE blocking agent, which protects against penetration of crystallizing media Excellent value for money Good resistance against wear, with abrasive and hardening mediums Recommended shaft surface hardness: HRC 50 Operating range Pressure [p max]: 25 bar, Velocity [v max]: 20 m/s Pressure [p max]: 100 bar, Velocity [v max]: 2 m/s Pressure [p max]: 100 bar Temperature: t = -50… +250 °C pH: 2 - 12 Density: 1.20 g/cm³ Practical useful application data: max. temperature: +200 °C Haupteinsatzgebiet Centrifugal pumps Mixer Agitators Autoclave Filter Refiner Kneader Paddle dryer Suitable for Pulp and paper industry Sugar industry Power plant technology Waste water technology Mining industry Variant Square shape P7 Form of delivery This packing can be manufactured in...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Meta-Aramid Fiber with PTFE Blocking Agent and Run-In Lubricant Characteristics Wear resistant, universal packing for applications with abrasive content High cross section density and structural stability, yet elastic and pliable Low friction, low shaft wear (HRC 45 shaft shaft surface hardness is sufficient) Clean packing, no contamination of media Operating range Pressure [p max]: 25 bar, Velocity [v max]: 20 m/s Pressure [p max]: 100 bar, Velocity [v max]: 1.5 m/s Pressure [p max]: 100 bar Temperature: t = -100… +280 °C pH: 1 - 13 Density: 1.40 g/cm³ Main application Centrifugal pumps Mixer Agitators Autoclave Filter Refiner Kneader Paddle dryer Suitable for Pulp and paper industry Sugar industry Waste water technology Form of delivery This packing can be manufactured in dimensions from 10 to 40 mm as well as in intermediate, inch sizes and special measurements. Available from 4 to 9 mm in square X-Section. 04 - 09 mm on 1kg spool 10 - 15 mm on 2,5 kg spool 16 - 25 mm on...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Hybrid braid in W-Profile made of heat conductive ePTFE Yarn with Meta-Aramid fiber reinforcement and Run-In lubricant Characteristics Clean packing with ultimate heat conductivity for abrasive products in pumps and other rotating equipment. Recommended shaft surface hardness: HRC 35 Porosity filling coating increases density and protects the packing in crystallizing mediums. W-Profile Reinforcement reduces shaft wear Operating range Pressure [p max]: 20 bar, Velocity [v max]: 20 m/s Pressure [p max]: 100 bar, Velocity [v max]: 2 m/s Pressure [p max]: 100 bar Temperature: t = -100… +280 °C pH: 1 - 13 Density: 1.55 g/cm³ Main application Centrifugal pumps Mixer Agitators Kneader Filter Suitable for Pulp and paper industry Chemical industry Power plant technology Waste water technology Applications with abrasive products and when white packing is required Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes and special...

Request for a quote

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Carbon Staple fiber with special Graphite Impregnation and silicon free Run In lubricant Practical useful application data: max. temperature: +200 °C Characteristics Volume stable, pressure stable High Cross section density due to special impregnation Excellent Value for money Graphitized all-round packing with Emergency run Capabilities Good wear resistance against abrasive and crystallizing products Recommended shaft surface hardness: HRC 45 Operating range Pressure [p max]: 20 bar, Velocity [v max]: 20 m/s Pressure [p max]: 250 bar, Velocity [v max]: 2 m/s Pressure [p max]: 150 bar Temperature: t = -50… +250 °C pH: 2 - 12 Density: 1.15 g/cm³ Practical useful application data: max. temperature: +200 °C Main application Centrifugal pumps Valves Mixer Kneader Agitators Suitable for Chemical industry Pulp and paper industry Waste water technology Community facilities Form of delivery This packing can be manufactured from 4 to 40 mm square as well as in intermediate, inch sizes...

Request for a quoteResults for

Hard surfacing - Import exportNumber of results

69 ProductsCountries

Company type

Category

- Aluminium sheets and bands (14)

- Robotics (3)

- Internal transport systems (2)

- Mechanical transmission systems and components (2)

- Disinfectants, non-medical (1)

- Detergents, household (1)

- Cleaning and maintenance products, industrial (1)

- Conveyor belts (1)

- Hand tools, non-power (1)

- Magnetic equipment (1)

- Metallurgy - machinery and installations (1)

- Plates, perforated - ferrous metal (1)

- Precious and semiprecious stones and pearls (1)

- Sensors (1)

- Sheet metal and strips, tinplate (1)

- Structures, aluminium (1)

- Tempering, metals - machinery and installations (1)

- Vacuum cleaners - industrial (1)