- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting system

Results for

Cutting system - Import export

WEBER FOOD TECHNOLOGY GMBH

Germany

The top models for industrial applications offer the latest technology and highest quality: As robust high performers in industry, the derinders ASB 460, 560 and ASB 770 are shining examples of pioneering technology in premium quality. The automatic initial cut control for rinds developed by Weber, combined with the spring-mounted cutting system ensures a clean initial cut and a high product yield. The new hygienic programme ensures quick and simple cleaning and is included as standard. Advantages Cut widths up to 460 mm Maximum output thanks to fully-automatic product process Minimum reworking of derinded cuts Precision thickness setting from 0-4 mm Options: Can be operated from left or right Product specific pressure devices Special sub-frames (height adjustment) Can be suspended over a shredding belt or on a C frame

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Weber Slicer 804 is among the most efficient systems in its class. The involute blade system cuts products up to 1,700 mm in length at a maximum speed of 2,000 slices per minute. The automatic central operation ensures quick product changes. Slicer 804 uses a blade head with an idle cut function, which positions slice thicknesses between 0.1 millimetres and 50 millimetres precisely in various presentation forms. The 400 mm wide and 180 mm high product throat permits four 90 calibre products or three 100 x 100 products to be processed simultaneously. The system includes a programme-controlled, automatically configurable product clearance height and width. Weber Hygiene Design ensures that the system is easy to clean. Options: Slice folder Variogripper Idle cut blade head

Request for a quote

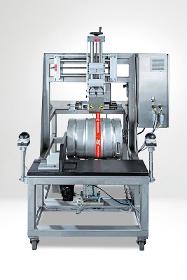

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The TNC-GG model series was developed to apply one or more labels to large cylindrical containers at the circumference. Instead of using „die-cut“ labels, it is also possible to handle continuous label material from the roll. Depending on the size of the product, the material is cut inside the system. The largest area of application for these systems is in the beverage industry, where beverage barrels (KEGs) are provided with a deposit banderol on the circumference and thus clearly indicate the owner of the returnable containers. Highly permanent label material is used for these applications, which can no longer be removed from the product without leaving residues. We also offer fully automated solutions for this.

Request for a quote

MESSER CUTTING SYSTEMS GMBH

Germany

The SicoMat® offers high productivity and maximum robustness: characteristics which are required particularly in shipbuilding and wind tower manufacture. With bevel cutting heads for oxyfuel cutting and plasma cutting, a wide spectrum of marking processes and the possibility of having a sandblasting or grinding head, the SicoMat® covers all production requirements.

Request for a quote

MESSER CUTTING SYSTEMS GMBH

Germany

You value flexibility? The MultiTherm® is multi-talented thanks to its variety of equipment options to fulfill your current and future application requirements. The MultiTherm® is a versatile cutting machine for plasma cutting, laser cutting, oxyfuel cutting and as well as in combination. The MultiTherm® is versatile and efficient with highest requirements concerning top quality and productivity.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MESSER CUTTING SYSTEMS GMBH

Germany

The Quicky® from Messer Cutting Systems is one of the most used portable cutting machines in the world with a reputation for reliability and quality second to none. Simple torch adjustment, both laterally and vertically and a cutting torch which comes as standard with nozzles for up to 100 mm thick Mild Steel cutting, the Quicky® is laid out for optimum performance. A wide range of options ensure flexible use for every application. The speed control is integrated ergonomically into the handle for ease of use.

Request for a quote

KLN ULTRASCHALL AG

Germany

For the assembly of plastic parts, which differ in size and condition and would therefore not be suitable for standard machines, we recommend the use of special equipment with several ultrasonic units for ultrasonic welding and processing methods. • Riveting • Welding • spot welding • punching • flanging • cutting • embossing • printing Multi-head systems These machines can also be used to accomplish complex tasks, e.g. the combination of different welding techniques, like spin welding and hotplate welding and for numerous automated processes

Request for a quote

DRAGLAB TECHNOLOGIES

Germany

•Available in 4 and 8 litter •Durable, reliable and Low cost •Built-in tank systems •High purity distilled water - conductivity approx 2,5 µS/cm (depends on incoming water) •automatic water and power cut-off when tank is full •automatic start, after distilled water is taken from tank •Electronic leakage-proof safety system •Thermostatic low-water cut-off safety system •High quality heating element •made of stainless steel •Easily accessed evaporator, condenser-tank for effortless maintenance •Easy to clean •All parts and tools for installation included •CE certificates

Request for a quoteResults for

Cutting system - Import exportNumber of results

9 ProductsCountries

Company type