- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- customs procedures

Results for

Customs procedures - Import export

SCHOLPP GMBH

Germany

Agility meets efficiency. Anywhere, any way. When we transport and relocate machinery, we move parts of all sizes. Whether we’re moving with heavy goods vehicles or by rail, plane or ship, our experts know which is the fastest, most cost-efficient and best way, and make sure everything arrives smoothly at your destination. Regardless of the mode of transport you need for your relocation, SCHOLPP can coordinate every element of the logistics, planning and monitoring. The SCHOLPP project team will also take care of all the necessary customs procedures. The loading, unloading and temporary storage of your goods is all in good, professional hands. SCHOLPP gets your equipment to its destination by any form of transport – road, rail, air or water.

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Testing plants in the area of bulk material processing Innovations made by Ebbecke Verfahrenstechnik To create a product exactly according to the ideas of the customer, standardized procedures are sometimes not enough. That’s why customers come from all over Europe to Ebbecke Verfahrenstechnik AG in Central Hesse – because our engineers are prepared to develop entirely new process engineering methods. With the new and further development of procedures and machines we are at the same time opening up alternative business areas for our customers. Testing and development without financial risk With all technical developments, our engineers keep the efficiency of the processes in sight. Because one thing is clear: An innovation can only prevail on the market if the development and subsequent purchase price remain within defined economic boundaries. This is where Ebbecke Verfahrenstechnik AG has been impressing for years with its pilot plants as centers of in-house development work. Toget

Request for a quote

ASSMY & BÖTTGER ELECTRONIC GMBH / A+B ELECTRONIC

Germany

Two modern AOI devices (automatic optical inspection) in 2D and 3D secure the manufacturing process during the SMT assembly. We use our X-ray inspection device to control the soldering process on components with connections under the housing. In addition to quality assurance, we also offer test and inspection procedures that are precisely tailored to your needs. In addition to circuit-specific in-circuit and burn-in tests, we can carry out application-related function tests in our test field. For specific tests, many customers send us the test procedures with the appropriate equipment directly. In this way we can check the functionality of your assembly without you having to tell us what exactly the tests are checking. Your advantages with A + B Electronic -Test procedures tailored to your needs -We are not just a service provider, we are a technology partner: A + B Electronic thinks your project with you and together we can successfully bring it into series production

Request for a quote

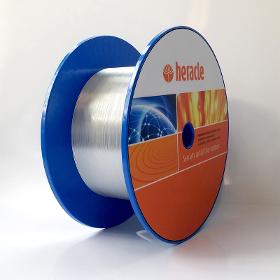

HERACLE GMBH

Germany

The featured Singlemode (SM 9/125) metal coated fiber operates in both, 1310 nm and 1550 nm wavelength ranges, according to G.652 A/B standards. The fiber is supplied with either 24 kt Gold or Aluminum coatings. As an electric conductor, these types of coatings provide the user with the ability to terminate the fiber directly to the coating, supporting hermetically sealed assemblies. Gold and Aluminum coated fibers are most capable of withstanding high temperatures and harsh environments compared to conventional coated fibers. The fibers have low stress corrosion susceptibility and offer superior mechanical protection in the most challenging harsh environments. All metal coated Singlemode fibers are 100 % quality tested to Heracle‘s stringent test procedures in accordance TIA/EIA and international Fiber Optic Test Procedures (FOTP). Custom specific tests to verify application requirements are available.

Request for a quote

HILGEFORT GMBH

Germany

Plant construction from Dinklage throughout the world Manufacturing large plants and components is one thing. Packing and transporting them carefully and safely before reliably assembling them on-site is an entirely different challenge. Hilgefort is a single-source supplier with many years of experience and highly qualified experts. Customers benefit from well-rehearsed procedures and a timely handover. Transport requires well-orchestrated logistics combined with considerable detailed knowledge: Roads on the route often have to be closed to traffic, traffic lights and road signs dismantled and then put back together again and sometimes even the roadsides have to be reinforced. The plant components not only need to be packed securely, they must also be packed correctly for the climate at the final destination. For example, this includes filling them with antifreeze agents for the leak test, as well as using fumigated wood for deliveries to the USA. The longest heavy goods...

Request for a quote

ARNOLD UMFORMTECHNIK GMBH & CO. KG

Germany

With Conform® components our customers can reduce their procurement and assembly costs: We handle the preceding processes thus enabling slimmer procedures at our customers’ own production facilities. So that we can meet the wide variety of component needs for our customers, we work within a network of certified partners. Some examples of components made to customer specifications: cold-formed parts in steel cold-formed parts in aluminium rubber decoupling elements plastic injection-mouldings stampings metal bending parts non-detachable washers or sealing rings

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Customs procedures - Import exportNumber of results

6 ProductsCountries

Company type