- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- production press

Results for

Production press - Import export

BORNEMANN GMBH

Germany

Coining dies made from alloy tool steel for the individual labelling of your products in cold or warm die. The machine dies are hardened annealed in our plant in accordance with the use. This category includes coining dies, signature dies, engraving dies, steel dies or press dies. Production is carried out in accordance with your drawings.

Request for a quote

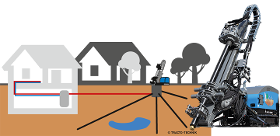

TRACTO-TECHNIK GMBH & CO. KG

Germany

Methods Products Videos Press & References Application partner FAQ Downloads

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

GRUNDOMAT Soil displacement hammers GRUNDORAM Pipe rammers GRUNDOPIT Mini steerable bore rigs GRUNDODRILL HDD systems GRUNDOBORE Auger boring units GRUNDOBURST Static pipe bursting GRUNDOCRACK Dynamic pipe bursting GRUNDOTUGGER 250 GEODRILL - Geothermal energy Methods Products Videos Press & References Application partner FAQ Downloads

Request for a quote

CRAEMER GMBH

Germany

Craemer is a specialist for constructing and manufacturing complex metal components and a well-known international supplier for the automotive, commercial vehicle, large domestic appliance and heating industries. The sheet metal components are sold to leading car producers, such as BMW, Mercedes Benz, GM, Volkswagen and Audi. Miele and other world brands are being supplied with white goods. The Craemer Group is one of the leading European manufacturers in the high volume serial production of car-modules, particularly components for seating structure and seatbelts. We process: sheet steel, high-strength sheet steel, high-grade steel and aluminium sheet Manufacturing process: hydraulic and mechanical presses with progressive die, transfer and servo direct technology as well as modern facilities for assembly production. Press capacity of between 3,150 and 25,000 kilonewton at a maximum table-length of 8,000 millimeters

Request for a quote

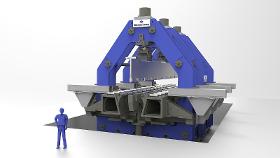

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp is number one in tailor-made plants for the leading manufacturers of pipeline pipes. These large-diameter pipes with longitudinal weld seams are manufactured using crimping, U-forming, and O-forming presses. Compared to other processes on the market, these three presses achieve high production outputs of up to 30 pipes per minute regardless of the pipe diameter. For these large presses featuring our proven metal frame construction, the heavy component parts and tools are manufactured in our in-house foundry. The three hydraulic presses present the essential forming units of a modern production line for longitudinally welded pipes with lengths of up to 18 m in three forming steps. For each of the three forming steps, Siempelkamp oers the optimal press and the associated equipment for the forming line (e.g., pipe transport, lubrication, measuring).

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Following product changes or a surface defect detected by the monitoring equipment, the aected mat section has to be rejected and discharged in time before reaching the ContiRoll®-infeed. This is ensured by Siempelkamp’s reject mat system. It is an in-line element of the forming line. Thanks to its modular design, it can be adjusted to the product parameters, enabling reliable press protection and a quick and material ecient plant restart. Features Drive/reject mat unit including track support Reject mat hopper Integration in the belt drive station Motor-adjustable table including belt deection nose Motor-adjustable belt cleaning brush Advantages Distance-controlled activation for an optimised material discharge and minimised rejects volume Options Including disintegrating rollers Including dust ap Hydraulic reject mat drive Nose stroke 3000 mm or 4000 mm

Request for a quote

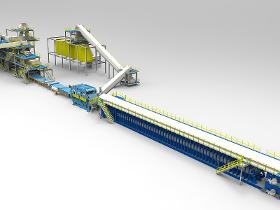

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Design and production of press-systems for the rubber industry is one major core competences of Siempelkamp More than 100 years of experience in rubber press lines More than 100 years ago, we put in operation the first conveyor belt press on the market. Only 20 years later, the first large vulcanizing press with a closed frame construction went successfully in operation. Even today, our presses and systems for the rubber industry have unqiue advantages: Durability, speed, high availability and efficiency, which are the most important arguments for our customers to choose a Siempelkamp plant. Proven technology that is trusted in the rubber industry With our broad expertise in the fields of rubber processing industry, we are the world market leader for steel cord and conveyor belt presses. A large part of the conveyor belts used around the world are manufactured on our equipment. Despite heavy loads, these conveyor belts always have to have best straight-running stability.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

A press for all processes Beside the pressing systems for industrial production, Siempelkamp manufactures laboratory press systems – both “try-out” presses for laboratoryscale tests with a starting pressing force of 150 t as well as presses for “fullscale testing”. The laboratory press systems are designed for maximum exibility. With it, all processes of composite production can be investigated. For example, it can be investigated whether press technology is an economic alternative for “autoclave” processes. All processes SMC with glass ber or carbon ber RTM PCM Organo-sheet consolidation Thermoplast forming Hybrid forming Integrated molding and joining of hybrid materials All control methods Force control with position monitoring Position control with force monitoring Each process step can be individually dened and programmed: All relevant process data are recorded and displayed.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Using a ContiTherm preheater upstream of the ContiRoll® press increases the production output of a wood-processing plant signicantly. It is an additional component integrated into the forming line and serves to preheat the mat before it is transferred to the ContiRoll® infeed to just below the temperature at which the glue starts to cure. A steam-air mix is conveyed through the mat. During this process, the steam condenses at the bres or particles, heating them up. The preheating temperature can be set most accurately by varying the steam content of the mix. The machine is separate into two to four sections (seen in working direction). Depending on the application these sections are designed for a unidirectional or a bidrectional steam injection or equipped with hot platens heated by thermal oil. The width of the steam boxes in an MDF-plant can be extended by additional segments to optimise steam-air conveyance.

Request for a quote

DEL DECUS ENTERPRISES LTD.

Germany

Satin Naturel MEN’s Organic Beard Oil – Premium organic quality for you and your beard Satin Naturel MEN’s Organic Beard Oil takes care of your beard by offering a high-quality moisturising product. Valuable, gently cold-pressed organic oils of almonds, argan nuts, jojoba seeds, grape seeds, and apricots nourish every individual hair of your beard. They absorb quickly into your beard without leaving any fatty residue. Using beard oil produces long-lasting benefits for your skin as well. Essential oils from select citrus fruits and cedar wood refine our beard oil, making it a 100% natural alternative to cologne. It has a fresh, forest scent that awakens memories of freedom and adventure. Satin Naturel MEN’s Organic Beard Oil – rich & effective men’s care that requires less than 5 minutes for lasting effects.

Request for a quote

W&K METALLVERARBEITUNG GMBH

Germany

We realize for you precise edging of workpieces up to a length of 4,500 mm and a material thickness of up to 8 mm. Your materials are brought into shape by our systems using state-of-the-art bending technology. We are able to edge all common metallic materials (sheet metal, stainless steel, aluminum etc.) with the help of our press brakes. Our production takes place with the tightest tolerances, so you get a high degree of precision from us.

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: Angle Material: EN AW-6060 (AlMgSi0,5), 3.3206 Type of production: pressed Condition: solution annealed, artificially aged Surface finish: anodised Standard: EN 573-3, 755-1/-2/-9 eClass 9.1: 35020101 UNSPSC 11.2: 30102306 Dimensions: Thickness (mm): 2 - 6 Length (mm): 6,000 Height (mm): 20 - 80 Width (mm): 10 - 50 RAL colour: E6 anodize EV1

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: U-section Material: EN AW-6060 (AlMgSi0,5), 3.3206 Type of production: pressed Condition: solution annealed, artificially aged Surface finish: anodised Standard: EN 755 eClass 9.1: 35020102 UNSPSC 11.2: 30101806 Dimensions: Thickness (mm): 2 Length (mm): 6,000 Height (mm): 20 - 30 Width (mm): 20 - 40 RAL colour: E6 anodize EV1

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: rectangular tube Material: EN AW-6060 (AlMgSi0,5), 3.3206 Type of production: pressed Condition: solution annealed, artificially aged Surface finish: mill-finish Standard: EN 755 eClass 9.1: 35020190 UNSPSC 11.2: 30102306 Dimensions: Thickness (mm): 1.5 -5 Length (mm): 6,000 Height (mm): 10 -100 Width (mm): 20 - 200

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: square tube Material: EN AW-6060 (AlMgSi0,5), 3.3206 Condition: solution annealed, artificially aged Type of production: pressed Surface finish: anodised Standard: EN 755 eClass 9.1: 35020190 UNSPSC 11.2: 30102306 Dimensions: Thickness (mm): 2 - 3 Length (mm): 6,000 Edge length (mm): 25 - 30 RAL colour: E6 anodize EV1

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: Flat Material: EN AW-6060 (AlMgSi0,5), 3.3206 Type of production: pressed Condition: solution annealed, artificially aged Surface finish: Mill-finish Standard: EN 573 eClass 9.1: 35020301 UNSPSC 11.2: 30102406 Dimensions: Width (mm): 10 - 300 Thickness (mm): 2 - 50 Length (mm): 6,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: Rectangular tube Material: EN AW-6060 (AlMgSi0,5), 3.3206 Type of production: pressed Condition: solution annealed, artificially aged Surface finish: anodised Standard: EN 755 eClass 9.1: 35020190 UNSPSC 11.2: 30102306 Dimensions: Thickness (mm): 2 - 3 Length (mm): 6,000 Height (mm): 20 - 30 Width (mm): 40 - 50 RAL colour: E6 anodize EV1

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: Flat Material: EN AW-2007 (AlCuMgPb), 3.1645 Type of production: pressed Condition: T4 acc. to EN 515 Standard: EN 573-3 eClass 9.1: 35020301 UNSPSC 11.2: 30102406 Dimensions: Thickness (mm): 8 - 80 Length (mm): 3,000 Width (mm): 20 - 150

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: Round Material: EN AW-6082 (AlMgSi1), 3.2315 Type of production: pressed Condition: T6 acc. to EN 515 Standard: EN 573-3 eClass 9.1: 35020302 UNSPSC 11.2: 30102406 Dimensions: Length (mm): 3,000 Diameter (mm): 15 - 200

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: handrail profile Material: EN AW-6060 (AlMgSi0,5), 3.3206 Type of production: pressed Condition: solution annealed, artificially aged Surface: mill-finish Standard: EN 573-3 eClass 9.1: 35020190 UNSPSC 11.2: 30102306 Dimensions: Width (mm): 50 Length (mm): 6,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: Square Material: EN AW-6060 (AlMgSi0,5), 3.3206 Type of production: pressed Condition: solution annealed, artificially aged Surface finish: Mill-finish Standard: EN 573/EN 485 eClass 9.1: 35020303 UNSPSC 11.2: 30102406 Dimensions: Edge length (mm): 8 - 60 Length (mm): 6,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: butt connector Material: EN AW-6060 (AlMgSi0,5), 3.3206 Type of production: pressed Condition: solution annealed, cold aged Surface: mill-finish Standard: EN 755 eClass 9.1: 35020190 UNSPSC 11.2: 30102306 Dimensions: Width (mm): 80 Length (mm): 6,000

Request for a quote

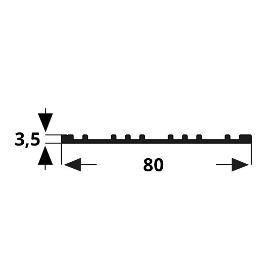

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

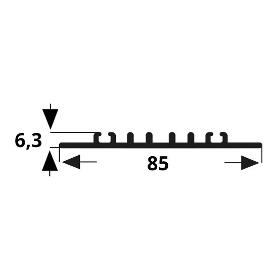

Shape: grooved butt connector, perforated Material: EN AW-6060 (AlMgSi0,5), 3.3206 Type of production: pressed Condition: solution annealed, not completely artificially aged Surface: mill-finish Standard: EN 755 eClass 9.1: 35020190 UNSPSC 11.2: 30102306 Dimensions: Width (mm): 85 Length (mm): 6,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: Z-section Material: EN AW-6060 (AlMgSi0,5), 3.3206 Type of production: pressed Condition: solution annealed, artificially aged Surface finish: mill-finish Standard: EN 10277/EN 10278 eClass 9.1: 35020105 UNSPSC 11.2: 30102306 Dimensions: Thickness (mm): 2 - 3 Length (mm): 6,000 Height (mm): 15 - 50 Width (mm): 15 - 40

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: angle Material: EN AW-6060 (AlMgSi0,5), 3.3206 Type of production: pressed Condition: solution annealed, artificially aged Surface finish: mill-finish Standard: EN 573-3, 755-1/-2/-9 eClass 9.1: 35020101 UNSPSC 11.2: 30102306 Dimensions: Thickness (mm): 2 - 12 Length (mm): 6,000 Height (mm): 10 - 200 Width (mm): 10 - 150

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: square tube Material: EN AW-6060 (AlMgSi0,5), 3.3206 Condition: solution annealed, artificially aged Type of production: pressed Surface finish: Mill-finish Standard: EN 755 eClass 9.1: 35020190 UNSPSC 11.2: 30102306 Dimensions: Thickness (mm): 1.5 - 5 Length (mm): 6,000 Edge length (mm): 15 - 150

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: Square tube, round edged Material: EN AW-6060 (AlMgSi0,5), 3.3206 Type of production: pressed Condition: solution annealed, artificially aged Surface finish: mill-finish Standard: EN 755 eClass 9.1: 35020190 UNSPSC 11.2: 30102306 Dimensions: Thickness (mm): 2 - 4 Length (mm): 6,000 Edge length (mm): 30 - 80 Radius (mm): 2 - 6

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: rectangular tube, 2 centre crossbars Material: EN AW-6060 (AlMgSi0,5), 3.3206 Type of production: pressed Condition: solution annealed, artificially aged Surface finish: mill-finish Standard: EN 573-3, 755-1/-2/-9, EN 15088 eClass 9.1: 35020190 UNSPSC 11.2: 30102306 Dimensions: Thickness (mm): 2 Length (mm): 6,000 Height (mm): 18 Width (mm): 200

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Shape: flat Material: EN AW-6060 (AlMgSi0,5), 3.3206 Type of production: pressed Condition: solution annealed, artificially aged Surface finish: anodised Standard: EN 755 eClass 9.1: 35020301 UNSPSC 11.2: 30102406 Dimensions: Thickness (mm): 2 - 4 Length (mm): 6,000 Width (mm): 20 - 30 RAL colour: E6 anodize EV1

Request for a quoteResults for

Production press - Import exportNumber of results

31 Products