- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precision

Results for

Precision - Import export

OTC DAIHEN EUROPE GMBH

Germany

With repetition accuracy of up to ± 0.07 mm, the new high accuracy robot can succeed in even the most demanding of tasks. The deviation from circular diameters of ≤ 10 mm is max. 0.09 mm - half as much as with commercial robots. • Position Accuracy: Highest precision regardless of robot position. • Precision machining: The best choice for laser welding and cutting, TIG, and other tasks requiring high accuracy. The best choice for laser welding and cutting, TIG, and other tasks requiring high accuracy. The main technical specifications at a glance: Number of axes: 6 Working Range (P-Point): R 1664 mm Max. payload capacity: 20 kg Positional repeatability: +/- 0,08mm Drive System: AC Servo Motor Drive Power: 7900 W Weight: 355 kg

Request for a quote

GSW SCHWABE AG

Germany

All rollers hardened and finepolished Multiple backup rollers to prevent deflection Specially suitable to feed highspeed stamping presses Parallel adjustment of upper roller bank with tilting via spindle type lifting devices With optional synchronized drive of pinch and work rollers Drive system via transfer gear box and universaljoint shafts with length compensation and quickrelease coupling Warpresistant stand in modular design to allow extension with catenary rollers, threading system, loop bridge or conveyors for operation as partsstraighteners etc. Hard chromed rollers Polyurethane coated rollers Hydraulic threading systems in different grades Motorized adjustment of upper roller bank with optional jobmemory Central edge guide adjustment via handwheel (optionally motorized) All roll drive Extricable and exchangable roller cartidges for easy maintenance Quickthreading feature for universaljoint shafts Movable base Manual or hydraulic loop bridge Conveyor belts... etc.

Request for a quote

GSW SCHWABE AG

Germany

When straightening becomes core competence and strip or parts need to be completely removed of their tension, GSW Precision Straighteners are the answer of choice. They handle up to 2000mm wide and up to 6mm thick materials in strip or plate. Highest stiffness, closest centerdistances and the active driving of all rolls allow for perfect flatness results. Our newest development – the HighPerformance Straighteners, series RMB – answer questions raised thru current material development leading to increasing material strength, lessening thicknesses or the use of sandwich materials Their enormous stiffness, large pinch rolls and closest center distances evenly deliver highest straightening forces. If material surface quality must be fully preserved, the 6high design option is the right choice. Here, intermittent rolls prevent marking caused by the backup rolls and allow for a perfectly clean strip or plate.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts used in machine support.Made by aluminium, machining and doing the sandblasting and natural anodize surface treatment.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC milling, can process a variety of materials,like Aluminum, Brass, copper,steel, Beonze, Steel Stainless .... Working length range:X:1-1066mm, Y:1-600mm,Z:1-600mm

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These precision and small parts are used in printer accessories.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Precision and complex machining.mask the hole and thread and then procedure in anodize.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material and create the desired shape. A wide variety of materials can be used in CNC turning, including:Aluminum, brass, bronze, copper, hardened metals, precious metals, stainless steel, steel alloys,ABS...

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These parts were made by stainless steel,which is produce from custom-made by drawing picture,we are strictly control the tolerance range to provoide perfects products.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

A flow valve is a critical component in various systems where the regulation of fluid flow is necessary. It’s designed to control the rate at which fluid passes through a system, ensuring that the flow matches the requirements of the application.Flow control valves are essential in industrial usage, hydraulic systems, and pneumatic systems. They play a crucial role in regulating the flow of fluids, ensuring optimal performance and efficient operation of machinery and equipment. Control valves can be actuated in various ways, including pneumatically, hydraulically, or with electric motors. Some valves, known as automatic control valves, do not require an external power source and operate solely on fluid pressure.When selecting a flow control valve, it’s important to consider factors such as flow rate and pressure requirements, material compatibility, and environmental conditions.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

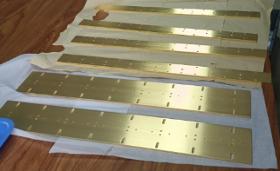

These accessories were made by copper, after CNC machined, then process brushing ,finally do the gold-plating .

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Camera precision aluminum cavity.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

CNC machining assemblies.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This parts used for mechanical parts.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Auto accessories parts.

Request for a quote

ROLLON GMBH

Germany

The PRECISION SYSTEM series of linear units are self-sustaining profile systems made of extruded aluminum and steel for the TK series, able to ensure excellent precision. The motion is achieved by means of precision rolled recirculating ball screws with preloaded or non preloaded ball nuts, depending on the models. Using the recirculating ball bearing technology for the screws and the rails ensures great performance to the linear actuators, such as: High precision and high axial forces High mechanical performance Low wear and tear Low resistance to movement High speed (for long pitch screws) The Precision System series consists of 4 distinct products with different features: TH, TT, TV, TK. PRECISION SYSTEM - TH TH linear actuators are rigid and compact, ball screw driven linear units, enabling high positioning accuracy and repeatability in all process phases with optimal performance assured, with a repeatability within 5 µm. Thrust force transmission is achieved by means of...

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

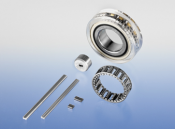

Special customer requirements occasioned us to produce selected bright steel specialities, such as antifriction bearing steel / ball bearing steel, which we also refer to as precision bright steel. The characteristic features of these antifriction bearing steels/ball bearing steels, etc. include the producible materials, attainable tolerances, achievable surfaces, available bar lengths, and obtainable strengths. Metering rods Ejector pins Fittings Ball bearings/Overrunning clutches >> Current alloy surcharges >> Current scarp surcharges VERSIONS AND FORMS SUPPLIED Drawing From 2.0 mm to 28.0 mm round, tolerance zone IT 9 Min. bar length 2,000 mm Max. bar length 5,000 mm (2.0 mm to 6.0 mm round) Max. bar length 7,000 mm (6.0 mm to 16.0 mm round) Max. bar length 9,000 mm (> 16.0 mm round and on request) Length tolerance ± 25.0 mm Grinding From 0.5 mm to 32.0 mm round, tolerance zone IT 6 (Rm up to 1,600 N/mm² for bright steel for standard parts) > 32.0 mm to 60.0 mm...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

Special customer requirements occasioned us to produce selected bright steel specialities, such as antifriction bearing steel / ball bearing steel, which we also refer to as precision bright steel. The characteristic features of these antifriction bearing steels/ball bearing steels, etc. include the producible materials, attainable tolerances, achievable surfaces, available bar lengths, and obtainable strengths. Metering rods Ejector pins Fittings Ball bearings/Overrunning clutches >> Current alloy surcharges >> Current scarp surcharges VERSIONS AND FORMS SUPPLIED Drawing From 2.0 mm to 28.0 mm round, tolerance zone IT 9 Min. bar length 2,000 mm Max. bar length 5,000 mm (2.0 mm to 6.0 mm round) Max. bar length 7,000 mm (6.0 mm to 16.0 mm round) Max. bar length 9,000 mm (> 16.0 mm round and on request) Length tolerance ± 25.0 mm Grinding From 0.5 mm to 32.0 mm round, tolerance zone IT 6 (Rm up to 1,600 N/mm² for bright steel for standard parts) > 32.0 mm to 60.0 mm...

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

Special customer requirements occasioned us to produce selected bright steel specialities, such as antifriction bearing steel / ball bearing steel, which we also refer to as precision bright steel. The characteristic features of these antifriction bearing steels/ball bearing steels, etc. include the producible materials, attainable tolerances, achievable surfaces, available bar lengths, and obtainable strengths. Metering rods Ejector pins Fittings Ball bearings/Overrunning clutches >> Current alloy surcharges >> Current scarp surcharges VERSIONS AND FORMS SUPPLIED Drawing From 2.0 mm to 28.0 mm round, tolerance zone IT 9 Min. bar length 2,000 mm Max. bar length 5,000 mm (2.0 mm to 6.0 mm round) Max. bar length 7,000 mm (6.0 mm to 16.0 mm round) Max. bar length 9,000 mm (> 16.0 mm round and on request) Length tolerance ± 25.0 mm Grinding From 0.5 mm to 32.0 mm round, tolerance zone IT 6 (Rm up to 1,600 N/mm² for bright steel for standard parts) > 32.0 mm to 60.0 mm...

Request for a quote

GHM MESSTECHNIK GMBH

Germany

Simple to use High precision Battery life > 6000 hours With calibration log

Request for a quote

GHM MESSTECHNIK GMBH

Germany

Waterproof device and probe Battery life of approx. 6000 h Calibration log included Simple to use

Request for a quote

GSW SCHWABE AG

Germany

Electropneumatic initiation to stay within the press cycle. Fineadjustment of individual nozzles allows precise lubrication right at the die – for an increase in dielife and productivity. No spray mist as only the pump is airpressurized.

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

In addition to the typical lift platform applications, LAWECO offers individual solutions for special lifting requirements. From material lifting systems for high-rise construction to freight traffic and transportation or lorry lifting platforms, LAWECO develops solutions for everything that needs to be lifted. The following designs chosen as examples reveal what is possible when combining creative engineering with experience of a harmoniously cooperating team.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We offer customized die-cast parts, stamped parts, deep-drawn parts, turned parts, milled parts and contact springs, both as small-precision and large parts. Partial or complete plastic and rubber injection molding of metal parts is also part of our portfolio. The manufactured metal parts can be completed with sealing elements, threaded inserts and bearing bushes. We also offer processes for cold pressing, as well as cost-effective surface finishing. We accompany our customers throughout the entire project process and organize the tool and sample production as well as the production (including surface finishing) and optionally also the assembly of the series parts.

Request for a quote

INGENERIC GMBH

Germany

The use of aspheres and acylinders offers substantial advantages: minimization of aberrations, increase in efficiency, reduction of optical elements and weight of the optical system. With its unique molding technique, INGENERIC combines cost effectiveness with highest serial precision. Molded optics can be structured/curved on one or both sides with a large degree of geometrical freedom and a flexible lateral contour. The lateral dimensions range approximately from 2.0 mm to 5.0 mm. Structures in the sub-millimeter range are feasible. Acylinders with larger dimensions are manufactured by INGENERIC’s well-proven grinding and polishing technology. The dimensions of these large acylinders can reach 60.0 mm in length and 120.0 mm in height. This technology is particularly adept for the manufacture of fused silica optics for applications with high power densities.

Request for a quote

GSW SCHWABE AG

Germany

All rollers hardened and finepolished Multiple backup rollers to prevent deflection Specially suitable for highstrength steel applications Parallel adjustment of upper roller bank with tilting via spindle type lifting devices With optional synchronized drive of pinch and work rollers Drive system via transfer gear box and universaljoint shafts with length compensation and quickrelease coupling Warpresistant stand in modular design to allow extension with catenary rollers, threading system, loop bridge or conveyors for operation as partsstraighteners etc. Hard chromed rollers Polyurethane coated rollers Hydraulic threading systems in different grades Motorized adjustment of upper roller bank with optional jobmemory Central edge guide adjustment via handwheel (optionally motorized) All roll drive Extricable and exchangable roller cartidges for easy maintenance Quickthreading feature for universaljoint shafts Movable base Manual or hydraulic loop bridge Conveyor belts... etc.

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

Hotmelt Extruder OptiMel has developed an extruder system that is specially adapted to the conditions and parameters in electronics encapsulation. A special design uses the advantages of the extruder when melting the materials and implements the injection via an additional piston unit. This process avoids pressure peaks and combines the advantages of extruders with the requirements when processing sensitive electronic components. product [extrusion tools, extrusion tools, hotmelt application systems, extrusion tool, extrusion tool, plastic welding extruder, hotmelt adhesive, extruder systems, extruder system, extrusion machines, hotmelt, hotmelt adhesives, extruder construction, extruder pumps, extrusion machine]

Request for a quote

NAGLER NORMALIEN GMBH

Germany

Flat tool steel in deffent alloys, standard sizes from stock

Request for a quote

TEST GMBH

Germany

The testing machines of model series 215 were developed and built for applications with extremely small measuring ranges, below 0.1 Ncm, and highest precision. They are for example used in watch idustry or medical technology. All torsion testing machines are equipped with the TesTController 850 that is TEDS compatible. The corresponding software TesTWinner® provides the user - besides to its free programmability - an immense repertoire of possibilities for standard test procedures and routine test execution, evaluation, presentation and further processing of results, automation of processes and much more. A wide application field is guaranteed by a comprehensive range of accessory.

Request for a quoteResults for

Precision - Import exportNumber of results

36 ProductsCompany type

Category

- Precision measuring instruments (6)

- Metal straightening machines (3)

- Optical measuring equipment (2)

- Automobiles (2)

- Silk-screen printing - machinery and equipment (2)

- Milling - machine tools (1)

- Sensors (1)

- SMALL METAL PARTS (1)

- Cameras, photographic (1)

- Astronomy - instruments and equipment (1)

- Foundries - copper, bronze and brass (1)

- Industrial robots (1)