- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- materials for seals

Results for

Materials for seals - Import export

P.V.A. PLASTIK-VENTIL-ARMATUREN GMBH

Germany

The 700 VA series float valve allows infinite adjustment of the level and has a flat float rod for mounting variable floats. It is suitable for use at high and low pressure and high temperatures up to 120°C, but not for use in drinking water. The stainless steel float model is suitable for simple mechanical regulation of levels in the food, pharmaceutical and chemical industries due to the VA materials and silicone seals.

Request for a quote

P.V.A. PLASTIK-VENTIL-ARMATUREN GMBH

Germany

Our mechanical PEKI valve series has been manufactured for decades from high-quality hot pressed parts and precision turned parts, which are assembled with modern injection moulded parts and sealing elements from German production. PEKI valves can be manufactured according to customer requirements in construction length, material of the seal as well as in chemical nickel plating.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Brass Surface Finishing - Standard Seal Material(s) FKM (Viton®) Working Temperature -25° C ... +200° C / -13° F ... +392° F Valve Design Poppet Valve Connection Push and actuate Push Sleeve Disconnection Actuate Push Sleeve Connect Under Pressure not allowed Application Industrial Hydraulic ISO Interchange ISO 7241-1, Series B

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Nickel Standard Seal Material(s) HNBR, FKM (Viton®), PTFE Working Temperature -20° C ... +100° C / -4° F ... +212° F Valve Design Poppet Valve Connection Screw Disconnection Screw Connect Under Pressure not allowed Application Construction Machinery ISO Interchange -

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Brass and Carbon Steel Surface Finishing Carbon Steel: Zinc-Plating and Thick-Film-Passivation (Chrome III) Standard Seal Material(s) NBR (Buna-N®) Working Temperature -25° C ... +100° C / -13° F ... +212° F Valve Design Flat Valve Connection Screw Disconnection Screw Connect Under Pressure not allowed Application Industrial Hydraulic ISO Interchange -

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Nickel Standard Seal Material(s) NBR (Buna-N®) Working Temperature -25° C ... +100° C / -13° F ... +212° F Valve Design Poppet Valve Connection Screw Disconnection Screw Connect Under Pressure not allowed Application Industrial Hydraulic ISO Interchange -

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Nickel Standard Seal Material(s) NBR (Buna-N®), PU Working Temperature -25° C ... +100° C / -13° F ... +212° F Valve Design Ball Valve Connection Screw Disconnection Screw Connect Under Pressure not allowed Application Industrial Hydraulic, Rescue and Tensioning Hydraulics ISO Interchange ISO 14540

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Stainless Steel V4A (AISI 316) Surface Finishing - Standard Seal Material(s) FKM (Viton®) Working Temperature -25° C ... +200° C / -13° F ... +392° F Valve Design Poppet Valve Connection Screw Disconnection Screw Connect Under Pressure Male Tip and Female Body allowed Application Industrial Hydraulic, Offshore, Rescue and Tensioning Hydraulics ISO Interchange -

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Nickel Standard Seal Material(s) NBR (Buna-N®) Working Temperature -25° C ... +100° C / -13° F ... +212° F Valve Design Poppet Valve Connection Screw Disconnection Screw Connect Under Pressure Male Tip and Female Body allowed Application Industrial Hydraulic, Rescue and Tensioning Hydraulics ISO Interchange -

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Nickel Standard Seal Material(s) NBR (Buna-N®), PTFE Working Temperature -25° C ... +100° C / -13° F ... +212° F Valve Design Flat Face Connection Screw Disconnection Screw Connect Under Pressure Male Tip up to the max. Working Pressure allowed Application Construction Machinery, Industrial Hydraulic ISO Interchange -

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Nickel Standard Seal Material(s) NBR (Buna-N®), PTFE Working Temperature -20° C ... +100° C / -4° F ... +212° F Valve Design Flat Valve Connection Screw Disconnection Screw Connect Under Pressure not allowed Application Construction Machinery ISO Interchange -

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Nickel Standard Seal Material(s) NBR (Buna-N®) Working Temperature -40° C ... +106° C / -40° F ... +223° F Valve Design Poppet Valve Connection Push Disconnection Actuate Push Sleeve Connect Under Pressure Male Tip/Female Body Application Construction Machinery, Industrial Hydraulic ISO Interchange -

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Plating and Thick-Film-Passivation (Chrome III) Standard Seal Material(s) Special compound Working Temperature -35° C ... +130° C / -31° F ... +266° F Valve Design Flat Face Connection Push and actuate Push Sleeve Disconnection Actuate Push Sleeve Connect Under Pressure not allowed Application Rescue and Tensioning Hydraulics ISO Interchange -

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Plating and Thick-Film-Passivation (Chrome III) Standard Seal Material(s) Special compound Working Temperature -35° C ... +130° C / -31° F ... +266° F Valve Design Flat Face Connection Push and actuate Push Sleeve Disconnection Actuate Push Sleeve Connect Under Pressure not allowed Application Rescue and Tensioning Hydraulics ISO Interchange -

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Nickel Standard Seal Material(s) NBR (Buna-N®), PTFE Working Temperature -25° C ... +100° C / -13° F ... +212° F Valve Design Flat Face Connection Push and actuate Push Sleeve Disconnection Actuate Push Sleeve Connect Under Pressure not allowed Application Agricultural and Forestry Machinery ISO Interchange ISO 5676

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Nickel Standard Seal Material(s) NBR (Buna-N®) Working Temperature -25° C ... +100° C / -13° F ... +212° F Valve Design Poppet Valve Connection Push and actuate Push Sleeve Disconnection Actuate Push Sleeve Connect Under Pressure not allowed Application Industrial Hydraulic ISO Interchange -

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Stainless Steel V4A (AISI 316) Surface Finishing - Standard Seal Material(s) FKM (Viton®) Working Temperature -25° C ... +200° C / -13° F ... +392° F Valve Design Poppet Valve Connection Push and actuate Push Sleeve Disconnection Actuate Push Sleeve Connect Under Pressure not allowed Application Industrial Hydraulic ISO Interchange ISO 7241-1, Series B

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Stainless Steel V4A (AISI 316) Surface Finishing - Standard Seal Material(s) FKM (Viton®) Working Temperature -25° C ... +200° C / -13° F ... +392° F Valve Design Poppet Valve Connection Push and actuate Push Sleeve Disconnection Actuate Push Sleeve Connect Under Pressure not allowed Application Agricultural and Forestry Machinery, Industrial Hydraulic ISO Interchange ISO 7241-1, Series A

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Nickel Standard Seal Material(s) NBR (Buna-N®) Working Temperature -25° C ... +100° C / -13° F ... +212° F Valve Design Poppet Valve Connection Push and actuate Push Sleeve Disconnection Actuate Push Sleeve Connect Under Pressure not allowed Application Agricultural and Forestry Machinery ISO Interchange ISO 7241-1, Series A

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

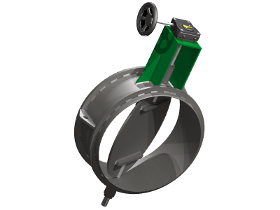

Throttle valve type ELA Use: The ELA valve was designed to be welded into an existing conduit. When properly installed, it guarantees a 100% airtight connection – without the need for additional sealing material. ELA is therefore able to also regulate and block „critical“ and dangerous media (that should not be allowed to penetrate to the outside). ELA is also the „easy way to regulate air.“

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Stainless Steel V4A (AISI 316) Surface Finishing - Standard Seal Material(s) FKM (Viton®) Working Temperature -25° C ... +200° C / -13° F ... +392° F Valve Design Flat Face Connection Push Disconnection Actuate Push Sleeve Connect Under Pressure not allowed Application Offshore ISO Interchange -

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Stainless Steel V4A (AISI 316L) Surface Finishing - Standard Seal Material(s) FKM (Viton®), PTFE Working Temperature -25° C ... +200° C / -13° F ... +392° F Valve Design Flat Face Connection Push Disconnection Actuate Push Sleeve Connect Under Pressure not allowed Application Industrial Hydraulic ISO Interchange ISO 16028

Request for a quote

CBG COMPOSITES GMBH

Germany

Anti-corrosion flexible one-sided self-adhesive butyl sealing strip, made of highly elastic, synthetic rubber (butyl) of soft rubber-like texture. It adheres reliably without heating. The butyl sealing strip is driven apart by the contact pressure, but due to its elasticity and plastic properties it penetrates into the smallest joints and unevenness and thus provides an optimum sealing. It can be drawn out to wafer-thin films by hand. Even high contact pressure level is not able to destroy the film. Non-ageing, UV-resistant, watertight, non-shrink, tight towards water vapour, seawater resistant. A sealant between metal, wood, plastics, organic glass and silicate glass with and among each other. It seals rivet and screw joints, flanged and folded connections. Sealing between metals prevents galvanic /electrolytical corrosion. Does not corrode Plexiglas, metal, wood, oil- and synthetic resin paints and does not contain any corroding ingredients.

Request for a quote

CBG COMPOSITES GMBH

Germany

fako® Sealing putty 3765, made of butylrubber, has been developed as a supplement to the fako® Sealing strip 3714, for most sealing purposes where absolute resistance to ageing is required and for which an intermediate layer of 0.8 mm to 1 mm has to be used. In combination with the Sealing strip 3714 most desired thickness’s can be obtained for seals. The putty does not become hard but remains plastic and elastic. To fulfil its requirements the putty has not only to be elastic but also plastic so that, when pressed, it will penetrate into any gaps and remain, thus forming a complete seal. Technically this is only possible through a combination of two basic materials with the same chemical composition but with different molecular weights. With two components the above requirement is met for both sufficient penetration depth and stability of the kit at the same time. By simple filling with a putty knife, you can obtain a min. thickness of approx. 0.2 to 0.3 mm. Priming is not required.

Request for a quote

IBK WIESEHAHN GMBH

Germany

Elastomers are macro-molecular, organic substances with little cross-linked structure. As a result, they do not melt, are insoluble, partly subject to swelling and are elastic. Elastomers are based on rubber which is processed into various kinds of synthetic rubber, depending on the monomer. The various kinds of synchetic rubberdiffer slightlys in their properties so that they are used for different applications with regard to temperature, hardness, elasticity etc. In addition to generally common mouldings such as Orings, our delivery range also includes customized mouldedarticles, profi le cords, punched or cut seals manufactured to specifi cations or to drawings, plates or rollers. Elastomer materials: - NBR - EPDM - CR - CSM - FPM - VQM - NR - EPDM

Request for a quote

IBK WIESEHAHN GMBH

Germany

Developed by IBK Wiesehahn, the secondary friction connection seal with H-profile has created an area of application in the industrial branch. The successfull conzept of “secondary friction connection” is based on the separation of bracing and sealing. Every functionary of the seal meet only one function. The seal is made of hard metal-profile and elastic sealing-material. The sealing-material is measured, that after reaching the block storage, the recovery behavior fully exists. A overpress of the sealing-material is basically excluded. Benfits of IBK SAFE-H® Seal: Secondary friction connection (block storage) Seal is chambered (secured against exhaust) High resilience of the flange connection Indenpendently pressure stage dimensions Easier to install regarding centring gauges Simplified warehousing High temperature resistance (up to 1000°C) High pressure resistance (up to 525 bar) Possibility of redefinition of the sealing zone with repair set

Request for a quote

EMKA BESCHLAGTEILE GMBH & CO. KG

Germany

EMKA offers a comprehensive product range of ingenious locking technology from a single source. The modular program structure allows a unique variety of components: quarter turns, locking-systems, handles, hinges and gasketings. The high quality and product standards are guaranteed by an excellent manufacturing know-how and by the certified process control according to ISO 9001. The Swinghandle model 1107 manufactured by Emka Beschlagteile is made out of a GF black polyamide construction. It consists of a shaft brass having mixing materials with seal characterized by zinc plated design. Additionally, the roundrods of the product is not available for usage if doorgauge is (Ts) > 4 mm

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The implementation of impact absorber stations provides effective protection against damage to the conveyor belt in the loading area. The belt is often pierced by sharp, large and bulky goods. Specially manufactured stations supporting impact bars absorb the impact speed. Repair and maintenance costs are thus reduced. In addition, the life expectancy of the conveyor belt and conveyor system is extended as well as the operating conditions significantly improved. Further advantages no jammed rollers causing belt misalignment absorb the drop energy, support the conveyor belt instead of the conveyor rollers in the transport area of the conveyor system and make a reliable running of the belt possible whilst ensuring the least possible friction. infinitely variable alignment to the angle of inclination by means of spindle displacement possible better material sealing due to adjustment of the material guide to within a millimetre

Request for a quote

BEULCO GMBH & CO. KG

Germany

Valve tapping bridge with service shut-off and for tapping 1 "- 2". Combination rubber insert chambered with several micro-sealing lips. Seal material according to KTW / W 270. Seal the bore with the auxiliary shut-off via the side outlet and seal it after tapping until the valve bonnet is reassembled. For each dimension, a top with matching clamp. scope of application • for plastic pipe (PE or PVC) DN 50 - 200 • for sluice-free, upper tapping under pressure by means of Rehbein auxiliary valve • for water up to PN 16

Request for a quoteResults for

Materials for seals - Import exportNumber of results

33 ProductsCompany type