- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- formed sheets

Results for

Formed sheets - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

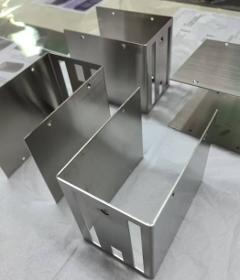

The process of sheet metal processing: Select the appropriate sheet metal, and carry out the necessary treatment and preparation, such as cutting, bending, stamping, etc Processing stage: forming the metal sheet, including cutting, bending, stamping, welding and other process operations Inspection stage: Conduct comprehensive quality inspection and evaluation of the final product, including appearance inspection, size inspection, performance testing, etc

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

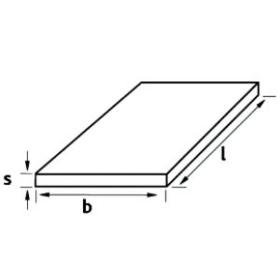

Flat steel products in roll or sheet forms obtained by cold-rolling of hot-rolled flat steel, with thicknesses ranging from 0.20 to 2.00 mm. meeting the expectations concerning the surface flatness and the width and thickness variation and the physical properties of the produced materials fully remain homogenous. Common Grades; As per EN 10130 DC01/DC03/DC04 , ASTM A619/DQ, SAE 1010 /1008/1006

Request for a quote

W. KÖPP GMBH & CO. KG

Germany

Foam rubber round cord rings, square or shaped profiles can be glued cleanly and durably to form round seals or frame seals. No mix-up possible With our molded parts and profiles made of foam rubber, a variety of technically safe solutions can be achieved. The extreme range of variations in terms of softness, elasticity, surface, shape and durability make foam rubber distinctive and indispensable as dimensionally stable seals, sound insulation elements, elastic bearings and for countless other applications. Let yourself be amazed by the versatility of our options and inspired by the safety and durability of our products. Foam rubber from KOPP - no mix-up! Your use of foam rubber We have foam rubber available for you as profile goods, ie foam rubber round cords, shaped profiles and square profiles in numerous standard dimensions. We also produce special profiles and molded parts according to your specifications. Foam rubber in sheet form completes this offer.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

The market for an ever-increasing array of consumer electronics parts is made possible by continuing innovation in integrated circuitry, new software applications and the exceptional properties of industrial aluminum, such as its light weight, high formability, superior heat dissipation, electrical conductivity, high corrosion resistance and attractive surface properties. Whether it is smartphones, tablets, laptops or flat screen TVs, aluminum is an integral component in the design, development and production of the latest personal devices and in-home entertainment systems. Novelis is leading the way in producing customized, premium flat-rolled aluminum for many consumer electronics parts and products, including aluminum enclosures and aluminum cases. Our aluminum products, developed according to customer specifications, are supplied in coil or sheet form, then slit or cut to length by third-party distributors or customers themselves.

Request for a quote

BS STEELWORKS GMBH

Germany

Cold rolled steel sheets are produced by re-rolling process of hot rolled steel sheets in order to provide precise thickness distribution across the coil. The surface roughness of the cold rolled materials is lower compared to hot rolled steels and suitable for painting and coating applications. According to the customers demands, it can be supplied in coil, slitted and cut to length sheet form. Our stock includes cold rolled steel sheet materials produced according to EN 10130, EN 10268, EN 10338, EN 10209 and others.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

For temperatures up to 450 °C. High-temperature furnaces Tempering furnace for car chassis stabilisers Previously cold-formed workpieces, e.g. stabilisers, are heated up in the tempering furnace at circulating air temperatures of up to 450°C and maintained at this temperature for an adjustable dwell time. This tempering increases toughness and dissipates residual stresses. Preheating furnace for frying pans and roasting tins Pan blanks are heated up to a temperature of approx. 390 °C and burnt free of all grease and oil residues. Enamelling furnace for frying pans and roasting tins The PTFE coating sprayed beforehand onto the frying pans is baked on at a temperature of approx. 450 °C. PTFE is used as a non-stick coating for frying pans and cooking pots on account of its low surface tension and good heat resistance. Chamber enamelling furnace for aluminium sheet metal forms Baking on of the single or multi-layer PTFE coatings at approx. 450 °C.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Our isothermal forging presses produce sophisticated, heavy-duty components for high-tech products. We furnish our customers with rst-class solutions including control systems for the ne-tuning of pressing speeds. Our presses are designed for high-precision applications indispensable in the aircraft/aerospace and medical engineering industries. The challenge here is to manage pressing speeds of 0.01 mm/s in controlled operation, which is ensured by our own electrical and hydraulic control engineering Siempelkamp also oers plants to be used for isothermal forging. They comprise the furnace, the feed manipulator, the forging press, the die heater, the hydraulic drive system and the entire automation technology. The plant control for isothermal forging presses monitors and documents the process parameters in compliance with the certication standards to be observed in the aircraft industry.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

As the leading provider of metal forming presses we are setting the standard worldwide. Our expertise in plant engineering and process technology is unique. This is because the individual performance features from the design to the startup of the equipment create a coherent and complete solution from a single source. Our hydraulic presses for metal forming are at home in cold and hot forming. From turbine disks for aircraft to pipeline pipes in the oil and gas industry to longitudinal beams in trucks: In our key industries of automotive, energy, rail and aerospace, we offer the right solution for every product. We supply not only the press, but also the associated process technology. Our range of services includes forging, thick sheet metal forming, raw forming, sheet metal forming and ring rolling. Our special systems for metal forming offer the perfect balance between the use of standard components and a custom-made design.

Request for a quoteSIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Application areas for straightening presses include the sheet metal processing industry. Here, this type of press is used for the straightening of semi-nished products, such as the levelling of uneven sheet metal and slab surfaces, which are used in subsequent processes. In addition to high straightening accuracy, Siempelkamp straightening presses provide a broad straightening spectrum and high exibility in the further processing of sheet metal. For materials with a tensile strength of 1,300 N/mm2, sheet metal with a thickness of approx. 300 mm can be processed To do so, the presses are equipped with one or several straightening rams which can be operated together or individually. The pressing force needed for straightening is applied across the entire press width. Sheet metal can be straightened by cold or warm forming with sheet temperatures of up to 600°C.

Request for a quote

EMKA BESCHLAGTEILE GMBH & CO. KG

Germany

EMKA offers a comprehensive product range of ingenious locking technology from a single source. The modular program structure allows a unique variety of components: quarter turns, locking-systems, handles, hinges and gasketings. The high quality and product standards are guaranteed by an excellent manufacturing know-how and by the certified process control according to ISO 9001. The 8B-155 series represents the latest addition to the 1079 hinge program. This lift-off, stainless steel, hinge is in accordance with AISI 316 (1.4401) and features a 180° opening angle. This model is equipped with chamfered ends that provide protection from dirt build-up allowing it to be used on prominent doors in sheet metal forming applications as well as food industry for both left and right side installations.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

A press for all processes Beside the pressing systems for industrial production, Siempelkamp manufactures laboratory press systems – both “try-out” presses for laboratoryscale tests with a starting pressing force of 150 t as well as presses for “fullscale testing”. The laboratory press systems are designed for maximum exibility. With it, all processes of composite production can be investigated. For example, it can be investigated whether press technology is an economic alternative for “autoclave” processes. All processes SMC with glass ber or carbon ber RTM PCM Organo-sheet consolidation Thermoplast forming Hybrid forming Integrated molding and joining of hybrid materials All control methods Force control with position monitoring Position control with force monitoring Each process step can be individually dened and programmed: All relevant process data are recorded and displayed.

Request for a quote

1A STAR TECHNISCHE KUNSTSTOFFE GMBH

Germany

Technical plastic : Polyethylene (Short : PE) Product name Polyethylene (PE or sub groups like PE-HD, PE-LD, PE-HMW, PE-UHMW, PE 300, PE 500, PE 1000 or RCH 1000 and many more) Delivery form Sheets, cuts, milled products, base profiles Specification Polyethylene - technical plastic Polyethylene ( Short: PE ) is a technical plastic that can be processed easil. It has a density of about 0,95g/cm³ and with that it's the second least weighing plastic of all technical plastics and just because of that it offers a very interesting price. The moisture absorbtion of PE is about 0,0 %. The material is really good against lyes and acids , has a self-lubricating effect and is easy to mill ( cut, milling, lathe, water jet cutting and welding ). Furthermore it is a great material for abrasive fraught parts in e.g. machine engineering ( PE UHMW ), as inlay for bulk containers or as a cutting boards in the food industry or households. We would like to advise you which kind of PE RG ist the...

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4016 (X6Cr17) Manufacturing method: cold-rolled, 2B Surface finish: pickled Norm: EN 10088-2 Dimensions: Thickness (mm): 3 - 4 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500 Factory filming: no film, no paper

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4301 (X5CrNi18-10) Manufacturing method: cold-rolled, 2R Surface finish: bright annealed Norm: EN 10088-1-2-3 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Thickness (mm): 0.5 - 3 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500 Factory filming: Standard film, no film, laser protection film

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4828 (X15CrNiSi20-12) Manufacturing method: hot-rolled, 1D Surface finish: pickled Norm: EN 10095 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Gauge (mm): 4 - 15 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Stainless steel Form: sheet Material: 1.4404 (X2CrNiMo17-12-2) Manufacturing method: cold-rolled, 2J Surface finish: brushed Ground sites: on one side Norm: EN 10088-2 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Gauge (mm): 1.5 - 2 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4571 (X6CrNiMoTi17-12-2) Manufacturing method: cold-rolled, 2B Surface finish: pickled Norm: EN 10088-2 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Thickness (mm): 0.5 - 6 Length (mm): 2,000 - 4,000 Width (mm): 1,000 - 2,000

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4404 (X2CrNiMo17-12-2) Manufacturing method: cold-rolled, 2B Surface finish: pickled Norm: EN 10088 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Gauge (mm): 0.8 - 6 Length (mm): 2,000 - 4,000 Width (mm): 1,000 - 2,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4301 (X5CrNi18-10) Manufacturing method: cold-rolled, 2B Surface finish: pickled Norm: EN 10088-2 Dimensions: Thickness (mm): 0.4 - 8 Length (mm): 2,000 - 6,000 Width (mm): 1,000 - 2,000 Foliation: Foil 4228, no foil, laser protection foil, no paper

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4828 (X15CrNiSi20-12) Manufacturing method: cold-rolled, 2B Surface finish: pickled Norm: EN 10095 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Gauge (mm): 1 - 3 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4301 (X5CrNi18-10) Manufacturing method: hot-rolled, 1D Surface finish: ground Norm: EN 10088-2 Ground sites: on one side Grain: Grit 240 Dimensions: Gauge (mm): 10 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4462 (X2CrNiMoN22-5-3) Manufacturing method: cold-rolled, 2E Surface finish: mech. descaled Norm: EN 10088-2 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Gauge (mm): 2 - 3 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4301 (X5CrNi18-10) Manufacturing method: hot-rolled, 1D Surface finish: pickled Norm: EN 10088-2 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Thickness (mm): 3 - 12 Length (mm): 2,000 - 6,000 Width (mm): 1,000 - 2,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4541 (X6CrNiTi18-10) Manufacturing method: cold-rolled, 2B Surface finish: cold-rolled pickled Norm: EN 10088 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Thickness (mm): 1 - 4 Length (mm): 2,000 - 3,000 Width (mm): 1,000 - 1,500

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4404 (X2CrNiMo17-12-2) Manufacturing method: hot-rolled, 1D Surface finish: pickled Norm: EN 10088-2 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Gauge (mm): 3 - 12 Length (mm): 2,000 - 4,000 Width (mm): 1,000 - 2,000

Request for a quote

KLÖCKNER & CO DEUTSCHLAND GMBH

Germany

Form: sheet Material: 1.4571 (X6CrNiMoTi17-12-2) Manufacturing method: hot-rolled, 1D Surface finish: pickled Norm: EN 10088-2 eClass 9.1: 35010511 UNSPSC 11.2: 30102505 Dimensions: Thickness (mm): 3 - 12 Length (mm): 2,000 - 4,000 Width (mm): 1,000 - 2,000

Request for a quoteResults for

Formed sheets - Import exportNumber of results

27 Products