- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cleaning machines

Results for

Cleaning machines - Import export

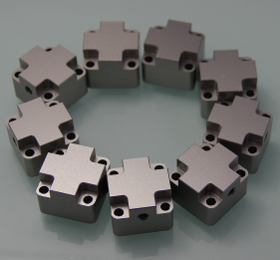

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories made by aluminum, which used in many fields ,such as industrial, medical equipment and other industries.

Request for a quote

WOMA GMBH

Germany

Manual cleaning with ultrahigh pressure water jetting technology often places high demands on the staff. Working overhead, in a stooped position, with respiratory protection or in heavy protective suits these and many other requirements can have a negative impact on work efficiency and safety. The WOMA Jetty now makes cleaning work with highpressure water more comfortable, more efficient and safer. This is made possible by a manipulator that is as manoeuvrable as it is robust and can be controlled via remote control. This means a consistently high quality of work even for hardtoreach work areas. Four extendable legs allow an enlarged footprint for outstanding stability in any environment. Depending on the task to be performed, different water tools can be used with the WOMA Jetty.

Request for a quote

KAMAT GMBH & CO. KG

Germany

We have specially developed the KAMAT Gekko 350 in order to clean large steel surfaces, for example ships, or large tanks, rapidly and without building scaffolding. Key technical advantages of the high-pressure surface cleaner are the thought-out combination of natural magnets and chain drive, as well as controllable high-pressure nozzles. The complete high-pressure system is remotely controlled conveniently and safely.

Request for a quote

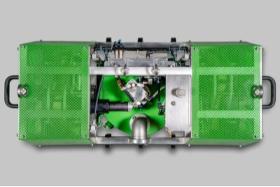

TECHNOTRANS SOLUTIONS GMBH

Germany

Lime and corrosion are hidden cost factors. Inevitably, these two “enemies of temperature control channels” prolong the cooling time, reduce the process safety and have a negative influence on the parts’ quality. The problem occurs insidiously in each plastic processing company, because lime and corrosion gradually build an insulation layer in the cooling channels and are thus responsible for a deteriorating heat transfer. Often the problem is not recognized until the demanded parts’ quality cannot be achieved any longer or if the complete system breaks down. The effect of cleaning the cooling channels of an injection mould is a reduction of cooling time up to 40 % (in individual cases even more), depending on the amount of deposits. The latest development, easy to use by the processor himself, is moldclean, a compact appliance which cleans polluted cooling channels in injection moulds and heat exchanger systems.

Request for a quote

JETCLEAN GMBH

Germany

The FERRET pipe cleaning machine is a user-friendly and handy tool for cleaning horizontal and vertical flue gas pipes. This eliminates the need for strenuous cleaning with brushes on a rod or awkward fiddling with rotating shafts. This significantly reduces the cleaning time. The FERRET machine is driven pneumatically. The oscillating brush propels the machine forward automatically and ensures an excellent cleaning result. Air consumption is low. A work area of approx. 0.5 m in front of the boiler is more than sufficient. Use the FERRET machine to clean your flue gas pipes up to a residual temperature of 150 °C. The use of special vacuum cleaner nozzles means that work is carried out virtually dust-free.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PERKUTE MASCHINENBAU GMBH

Germany

Cleaning machine Clean-o-mat SP 80 - 2 T for turbine components out of the aircraft industry Toploader SP 80 - 2 tank machine with additional rinsing with fresh water and impulse blowing off for turbine components out of the aircraft industry

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Special solution: Parts cleaning machine Clean-o-mat SP 80 with additional hand-spraying device Toploader Clean-o-mat SP 80 with additional hand-spraying device (160 bar/optional), inspection window and lighting for the manual cleaning of complex parts.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

PARTS CLEANING FOR REPAIR AND MAINTENANCEImportant components require thorough and regular cleaning and maintenance, especially in industry, mechanical engineering and the automotive sector. Our TRT 83 x 37 cleaning trough removes grease, lubricants and other residues thoroughly and reliably, before the components are reinstalled. WHICH WORKPIECES CAN BE CLEANED? You can use the TRT 83 x 37 cleaning trough to effortlessly clean workpieces measuring up to 80 cm in length and 30 cm in diameter. Here are some examples: Bearing shells and covers Engine components Gearbox components Shafts and axles Labyrinth rings Bearings, bearing units and bearing housings

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

As the conveying machines are manufactured according to customers requirements they are easily integrated in the existing production layout. A variety of transportation systems and the possibility of integration allows for a very large application area; e.g. cleaning of massproduced goods, long materials, boxes, containers and pallets. The PERKUTE-system: economically - environmental – effektive Basic equipment Made of stainless steel Compact construction Simple operation User-friendly Easy maintenance Wide range of basic equipment Lateraly build-up tank, filter baskets incl. Temperature indicator for every region Low water level protection as protection against dry running Minimum operating cost because of tank insulation Maintenance hatch in the hoods

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

The approved and economic system of this multi-tank-machine offers various possibilities for all applications in the area of the production and manufacturing industry. Most different process steps like cleaning, rinsing, inter-rinsing and drying makes the machine the all-round talent. The PERKUTE system: economically - environmental – effektive Basic equipment Made of stainless steel Compact and sturdy construction Simple operation Adjustable feed fork-lift facility incl. 3D-blast pipe system incl. fan nozzles Low water pressure switch as dry-run protection Electronic basket drive Tank cover in the return flow, filter basket incl. Long wash liquid service life due to the skimmer (washing tank) Programmable operation operating counter incl. Automatic steam extraction by air blower Powerful washing pump in the washing- and rinsing tank High permissible basket load 2" socket slide valve for the tank emptying Safety limit switch at cover Separate washing- and rinsing tank

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

As the conveying machines are manufactured according to customers requirements they are easily integrated in the existing production layout. A variety of transportation systems and the possibility of integration allows for a very large application area; e.g. cleaning of massproduced goods, long materials, boxes, containers and pallets. The PERKUTE-system: economically - environmental – effektive Basic equipment Made of stainless steel Compact construction Simple operation User-friendly Easy maintenance Wide range of basic equipment Lateraly build-up tank, filter baskets incl. Temperature indicator for every region Low water level protection as protection against dry running Minimum operating cost because of tank insulation Maintenance hatch in the hoods

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Removal of adhesive residues on grinding instruments with the Spray cleaning device Clean-o-mat RC 82 Parts cleaning machine for removal of adhesive residues on grinding instruments with approx. 100 bar pressure. The nozzle tube system and the clamping device are adaptable to the grinding wheel diameter.

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Industrial parts cleaning with the Perkute Toploader Series The PERKUTE rotating basket cleaning machine from the Toploader series is used wherever effective and inexpensive cleaning of parts of any kind is necessary. The rotating basket, designed for large weights, is powered by means of a low-wear friction wheel drive and the aqueous cleaning in the spray process takes place by means of a nozzle pipe system with special flat-spray nozzles that is arranged on 3 sides. A powerful washing pump supplies the system with the necessary pressure and volume flow. The parts cleaning machines, made completely of non-rusting special steel, istinguish themselves by their compact and robust construction as well as simple handling. They are mobile to deploy and designed to be space-saving. Customisation for individual cleaning tasks can be optimised through a comprehensive range of accessories.

Request for a quote

MAYFRAN GMBH

Germany

Coolant filter used for central coolant cleaning for several machine tools. The universal central filter for short swarf

Request for a quote

AMBIDELUXE GMBH

Germany

30 Cleaning Tablets for Coffee Machines Cleaner compatible with Jura Siemens Bosch Nescafe Andrew James Delonghi and many more for Automatic Filter Pad Capsule Machine - Best Quality: ✓ Made in Germany ✓ 30 tablets 2.0 gramm each ✓ In a recloseable plastic can for dry storage ✓ Just 1 tablet for a clean coffee machine ✓ For a long life of your coffee machine - The cleaning tablets for many brands: ✓ Jura ✓ WMF ✓ Miele ✓ Siemens ✓ Bosch ✓ Andrew James ✓ Saeco ✓ DeLonghi ✓ Nespresso ✓ Delonghi ✓ Tassimo ✓ Krups and many more. For automatic coffee machines and filter pad and capsule coffee makers - For every day usage: Take care for your coffee machine at home, in the office or in gastronomical enviroment. For a clean coffee machine. - Long coffee experience: Because of the daily usage of your coffee machine the taste of the coffee can change. The AmbiClean Cleaning Tablets will change this and your coffee will taste as good as before

Request for a quoteResults for

Cleaning machines - Import exportNumber of results

16 ProductsCompany type

Category

- Cleaning machines, industrial (8)

- High-pressure cleaning machines (2)

- Street-cleaning machines (1)

- Cleaning, industrial (1)

- Cleaning and maintenance products, household (1)

- Plastics - machines and material for industry (1)

- Adjustment - machine tools (1)

- Dishwashing machines for institutions (1)

- Industrial sprayers for surface treatment (1)