- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- fully automatic labelling machines

Results for

Fully automatic labelling machines - Import export

SESSIONS UK - LABELLING MACHINES

United Kingdom

The Rotoring labelling system is a high speed round product labeller for stand alone or inline operation. Designed to label almost any round product from 20 to 100mm in diameter including register labelling, the Rotoring features quick change product wheels, easy setup and full diagnostics during runtime ensuring maximum output for any production process. ** Click for more **

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Synchronized transmission and drive by gear with one belt. The change of transmission belt will be finished quickly. Compared to the type of traditional multilayer whose change and maintain need more than six hours, its maintenance is easy and maintain is simple, so it doesn’t influence production. 2.Cutter head unit: The new style cutting knife droved by servo motor, with high speed, more stable and precise, shrinks perfectively.Synchronous locating device enables the tolerable error to ±1mm.Unit cutter head plane design in China which applies to the container of D30mm—D130mm.You never need to change or debug it. Cutter head original transducer is inside the cutter head and when you take down cutter head, you do not need to correct the synchronous belt. It also has unique light touch human-machine screen, that means, auto search original location as well as safety and convenience which is ahead of other congener products. 3. Label feeding unit: Single material shelf with

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

This fully automatic sleeve labeling machine is suitable for various kinds of bottles,like round bottles, square bottles,oval bottles,etc.This machine can automatically feed and cut film,and it can sleeve labels precisely,greatly saving labor and improving work efficiency.The machine can be widely used for beverage bottles,cosmetic bottles,shampoo bottles,etc. The touch screen control panel makes the working parameter is visual,the precise adjustment can be easily achieved according to operation Equipped with high quality electric eye,It can pull film automatically,it is more convenient and easier to operate the machine. The bottle separating component can help to separate bottle and adjust bottles distance,ensure the bottle can be labeled in order,improve the labeling effect. Rotary knobs are designed for adjusting the position of different mechanisms, make sure the machine can sleeve label precisely.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

This fully automatic sleeve labeling machine is suitable for various kinds of bottles,like round bottles, square bottles,oval bottles,etc.This machine can automatically feed and cut film,and it can sleeve labels precisely,greatly saving labor and improving work efficiency.The machine can be widely used for beverage bottles,cosmetic bottles,shampoo bottles,etc. The touch screen control panel makes the working parameter is visual,the precise adjustment can be easily achieved according to operation Equipped with high quality electric eye,It can pull film automatically,it is more convenient and easier to operate the machine. The bottle separating component can help to separate bottle and adjust bottles distance,ensure the bottle can be labeled in order,improve the labeling effect. Rotary knobs are designed for adjusting the position of different mechanisms, make sure the machine can sleeve label precisely.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Like all of our labelling systems, this model has a modular design and can be expanded at any time. The advantages such as low set-up costs, high availability and multiple use in different production lines are obvious. The adaptation to the different products takes place by simple adjustment of the machine components and is possible without tools. The VRM-DS model includes a 3-roller turning station and can be used for an output of up to 60 products per minute. It is characterised by the highest labelling accuracy and can optionally align the products using a welding seam, print mark or other feature before labelling (target zone labelling). For larger quantities of up to 250 products/ min the VRM-RB model is used. Model: VRM-DS | Cylindrical and quadratic products | up to 60 products/min VRM-RB | Cylindrical and quadratic products | up to 250 products/min VRM-DSRB | Cylindrical and quadratic products | up to 250 products/min

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The PAE range is an innovative new generation of pallet labellers that can label pallets on up to three sides with either pneumatic and/or electric traversing axles. The labels are printed with individual data in real time immediately before dispensing. The series is designed to integrate thermal transfer printing modules from different manufacturers. Automatic height adjustments are available as an option in order to Application heights on the pallet to start up. The complete traceability of products is essential nowadays, which is why interest in intelligent pallet labelling processes is so high. The system can handle label formats up to DIN A4 format, enabling product labelling according to the global GS1 standards.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The system is used for labelling or printing flat products such as postcards, flat folding boxes, mailing bags or textile blanks, regardless of the format. The products are fed into the loading chute by the operator and are then destacked layer by layer from below and fed past the labeling or printing or inspection unit. The finished products are then collected in an exit chute or a collection box. This system was developed for a capacity range of up to 100 products/min. For processing higher numbers of products/min, the HSF model series is available which, in addition to a longer conveying distance for setting up different stations also provides the option of a product ejector to automatically remove NIO products from the process and collect them in a separate collection box. The tool-free adjustment enables the shortest changeover times for batch/product changes.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Fully automatic labelling machine for labelling drums in accordance with the GHS Directive. All chemicals are subject to mandatory classification and labelling before they are placed on the market, and they are often marketed in drums and hobbocks of various sizes. This places increased demands on the flexibility of the labelling unit in terms of print data, multi-colour printing and application height (labelling height). Often, several labels are applied to the circumference of the keg (product label, hazardous goods label(s) and logistics label. For this purpose, the system can be equipped with several label dispensers and/or several printing and dispensing systems. Labelling can be carried out in continuous operation or at a standstill. Depending on the application and labelling requirements, the labelling system can also be positioned at a drum labelling station.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Fully automatic labelling machine for labelling drum pallets IBC Conatiner All chemicals are subject to mandatory classification and labelling before they are placed on the market. Often, several labels (product label, hazardous goods label and logistics label) are used up on the containers or drum pallets. Labelling can take place in a continuous flow or at a standstill. Vacuum belts are used for transferring labels to the drum, which can process different label sizes with the appropriate special vacuum plate. The IBLM labeller can be used as a stand-alone labeller or integrated into existing production lines and filling lines.

Request for a quote

FERPLAST SNC

Italy

The TRITONE labeller was made by dividing it into modules, so as to allow use in both horizontal and vertical positions and easy integration into the packaging lines. The control is entrusted to a microprocessor, which manages the pre-separation in mm. and regulates the speed from 0 to 30 mt. min. TECHNICAL FEATURES Stepper motor with variable speed from 5 to 30 mt./min. Maximum label width mm. 100 Minimum label width mm. 20 Maximum label length mm. 300 (higher on request) Minimum label length mm. 20 Label application delay via electronic setting Label application precision mm. 0.5 Label reel with internal diameter mm. 40-76, external mm. 300 max Rewinding roller for silicon paper recovery Variable reading photocell for label stop REFLEX photocell for product detection End of roll alarm (optional) Electronic control unit Switch Stroke counter with zero setting Protection fuses Potentiometer for speed adjustment of labeling head Power supply 220 V 50 Hz. Dimensions mm.

Request for a quote

FERPLAST SNC

Italy

MANUAL NUMERICAL AND ALPHANUMERIC PRICING MACHINES FP-PRZ SERIES WITH 1 PRINT LINE FOR LABELS 26x12 mm wave The manual pricing machines are suitable for printing prices, dates, lots, deadlines and codes on adhesive labels. They are particularly suitable for use in the food sector, where it is necessary to specify batches and expirations of the products and wherever it is necessary to label. The pricing machines produce numerical or alphanumeric writings on a print line and depending on the model the printable characters can be 8 or 10. The 26x12 labels are available only in wave form and the most used are white, however it is also possible to request other colors and pre-printed. The characters of the pricing machines can be: - numeric: all numbers with dashes and currency symbols (£/€/$). - alphanumeric: all numbers and letters WITHOUT currency symbols

Request for a quote

FERPLAST SNC

Italy

D-FPWR BOTTLES - SEMI-AUTOMATIC LABELING MACHINES FOR ROUND PRODUCTS Semi-automatic applicator for rolls of self-adhesive labels with maximum width mm 200/300 on bottles and cylindrical products with a diameter of mm 20 to mm 130 Main features: - Sturdy construction in steel and aluminum - Motorization of the product rotation roller and the drawing of the labels by means of stepper motors with variable speed and electronically synchronized - Microprocessor management electronics with storage of 40 working formats - Possibility to apply a wraparound label or front/back label and also with a different size with adjustment of the distance between the two programs - Maximum label width mm 200/300, and maximum coil diameter 300 mm - Change of format extremely simple and fast

Request for a quote

FERPLAST SNC

Italy

DFP-WR is a series of semi-automatic distributors of adhesive labels on rolls, completely made of steel, easy to use, versatile for any type of label you normally use. Available in widths up to 100 mm. or 200 mm. The holder can be adapted to any core can accept rolls up to 300 mm. diameter, thus offering long autonomy.The labels are read by two sensors that self-learning by the microprocessor automatically identify the difference in transparency between the label and the backing paper, presenting the label on the peeler, almost completely detached. Withdrawing the label, the next pop-up automatically. The control board also allows you to stop the rotation of the motor when coil is finished, or in case of paper breaking. It sign the anomaly with a sound signal. There is an electromechanical sensor for transparent labels and a preset counter for the regressive or progressive counting of the labels. The use of the battery version allows to work for about 4 hours without power supply.

Request for a quote

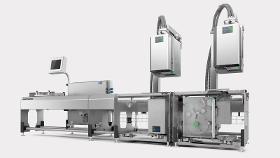

BIZERBA SE & CO. KG

Germany

Big 3: Performance, Plug-In ® label and Quality Check Inside - more customer benefits for future requirements The Automatic Weigh Price Label Systems from Bizerba. Introducing the GLM-Ievo 150 capable of weighing and labelling up to 150 packages per minute. Designed for automatic weighing and labelling of pre-packaged goods comes in different versions from the entry level intelligent weigh price goods labelling system GLM-Ievo 70 (70 packages per minute) to the GLM-Ievo 170 weigh price goods labelling system (170 packages per minute) Higher package rates are available upon request. Due to its modular design, it can be optimally configured for products and performance requirements in the industrial food production area. With the Bizerba _connect.BRAIN Industrial Software makes this system an even more attractive addition to your production plant. The intuitive software enables you to connect the Automatic Weigh Price Label Systems to existing third party hardware and software....

Request for a quote

FERPLAST SNC

Italy

MANUAL NUMERICAL AND ALPHANUMERIC PRICING MACHINES FP-PRZ2 SERIES with 1 or 2 PRINT LINES FOR LABELS 26x16 mm rectangular and wave shape The manual pricing machines are suitable for printing prices, dates, lots, deadlines and codes on adhesive labels. They are particularly suitable for use in the food sector, where it is necessary to specify batches and expirations of the products and wherever it is necessary to label. The pricing machines produce numerical or alphanumeric writings on one or two printing lines and depending on the model the printable characters can be from 8 to 10 per line. The 26x16 labels are available in wave and rectangular format. The most used are white, however it is also possible to request other colors and pre-printed. The printing lines of the pricing machines can be: - numeric: all numbers with dashes and currency symbols (£/€/$). - alphanumeric: all numbers and letters WITHOUT currency symbols.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The TNC-DS series is used to label cylindrical products on the circumference. For this purpose, the product is manually placed in the product turning station. The labelling process is triggered by actuating the foot switch or the optionally available 2-hand control. The product is rotated, and the label is applied precisely to the circumference of the label. As standard, the model is available with different roll widths (100 to 300 mm) and different label applicators (60 to 250 mm wide) or print- and apply systems. Optionally, the labels can be aligned using a welding seam or other product features. If front and back labels are on one label roll, the system can also place several labels on the circumference. The distance between the labels can be adjusted in the PLC. Depending on the operator, the output of this model is between 10 and 15 products/min.

Request for a quote

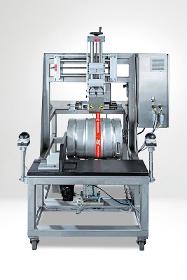

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The TNC-GG model series was developed to apply one or more labels to large cylindrical containers at the circumference. Instead of using „die-cut“ labels, it is also possible to handle continuous label material from the roll. Depending on the size of the product, the material is cut inside the system. The largest area of application for these systems is in the beverage industry, where beverage barrels (KEGs) are provided with a deposit banderol on the circumference and thus clearly indicate the owner of the returnable containers. Highly permanent label material is used for these applications, which can no longer be removed from the product without leaving residues. We also offer fully automated solutions for this.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Thanks to the TNC-F model series, semi-automatic labelling of shaped bottles becomes very easy. The front and back labels should be on a carrier material. The product is inserted into a product pickup device. As soon as the 2-hand operation is activated, the system starts to pick up the product in the two format pucks, rotates and aligns the product before the front and back labels are applied exactly to the desired positions. By exchanging the format parts of the product pick-up device, cylindrical or angular products can also be processed and labelled with several labels in addition to the shaped bottles.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

For precise labelling, products with an accessible cavity are manually placed on a format mandrel. By actuating the foot switch or the optionally available 2-hand control, the labelling process is triggered, the product is rotated, and the label is applied precisely to the circumference of the product. If front and back labels are on one label roll, the system can also place several labels on the circumference. The distance between the labels can be adjusted in the PLC. Optionally, the labels can be aligned using a welding seam or other product features (such as opening tabs or lid recesses for tubes). A pneumatic ejection makes the removal process superfluous and blows the well labelled products into a collection box

Request for a quote

HERMA GMBH

Germany

HERMA wrap-around labeler 152C: precise labeling at low cost Equipped with the high-performance labeler HERMA 500, it is suitable for up to 200 cylindrical products per minute The easy-to-maintain solution with a folding belt and back pressure plate offers amazing performance and a fast return on investment Most adjustments can be made without tools with little time required With the optional roller prism technology, even spiral misalignment is almost completely eliminated; even aligned labeling succeeds perfectly Clean Design with closed holes, minimum gaps and grooves, and rounded corners protects the 152C from contamination and makes it easy to clean and maintain Installation of a printer unit such as a hot stamp or thermal transfer printer is possible without any problems Is now available much faster due to the Clean Design and digitized ordering processes, optionally in EU or US versions.

Request for a quote

HERMA GMBH

Germany

High performance without compromise The wrap-around labeler is available in two versions: HERMA 132M - With the continuously rotating starwheel, up to 400 products/minute can be labeled. HERMA 040M - With the clocked starwheel, up to 120 products/minute can be labeled: Precision and reliable production make this easily convertible solution unbeatable - the clocked rotary star guarantees precise labeling with extreme performance. The compact, modular design from standard components enables the machines to be precisely and yet very economically assembled for individual requirements of individual users. Cylindrical products with one or two labels on the circumference can be labeled more cost-effectively and in less time. In addition to cost-effectiveness, the labeling system for wrap-around labeling offers a high standard of safety.

Request for a quote

HERMA GMBH

Germany

HERMA 211 HC - Feeding demand for personalized medical care The wrap-around labeler 211 HC reliably processes even the smallest batches and products that tend to tip over. Ideal machine for small vials, syringes and cartridges, where the semi-automatic machine can score with its economy in frequent format changes. Labels are applied by rotating these products horizontally between two motorized rollers and the pivot peel plate with application roller. The semi-automatic labeling machine combines the high flexibility of manual product feeding with a complete equipment according to pharma specifications, including a printer for variable data and codes, and a camera for print and code verification. Optionally available with the innovative bad label return for the reliable removal of bad labels. The new 211 HC is therefore tailor-made for processing healthcare products.

Request for a quote

HERMA GMBH

Germany

Benefits of the HERMA 414 at a glance: Semi-automatic top labeling designed for a wide variety of formats on both flat and curved surfaces. For label dimensions of up to 100 mm in length and 160 mm in width. The heart of the system is the powerful HERMA 500. Entire machine is controlled by the HERMA 500’s basic drive unit. All necessary parameters can be conveniently set on the integrated operator display. Can be adjusted to different product diameters in no time at all. No control box or PLC required.

Request for a quote

HERMA GMBH

Germany

Benefits of the HERMA 211 at a glance: Semi-automatic wrap-around labeler for labeling cylindrical products. The spectrum of possible product diameters ranges from 20 to 120 mm. Fast retooling. Adjustable to different product diameters in no time at all. Heart of the system is the high-performance HERMA 500 applicator. An additional basic drive unit from the HERMA 500 is used to drive the roller prism. No control box or PLC necessary. All necessary parameters can be easily set using the integrated operator display. Aligned wrap-around labeling optionally available.

Request for a quote

HERMA GMBH

Germany

Powerful and sturdy side labeling system: The 362E two-sided labeling machine lets you label up to 200 products per minute. Fast, durable, compact & excellent price-performance ratio. A multitude of optional extras are available, and the machine can be fitted with a PLC controller with a very clear and easy-to-configure operator panel . Two high-performance applicators ensure a high output, even during continuous operation. The design means that no guards are required, which saves space. However, the enclosed stainless-steel base makes the labeling machine extremely stable. Handwheels with digital position indicators let you reproduce your optimum settings at all times. The labeling machine can be converted for wrap-around labeling in no time flat. The missing label check and product ejection features make the 362E fit for particularly demanding tasks.

Request for a quote

HERMA GMBH

Germany

Compact, precise and cost efficient Businesses often face a difficult decision: If the dimensions of your products are ordinary, can you get by with an inexpensive and compact standard system with little scope for expansion? Or does the application require a more complex and expansive custom machine with longer lead times because you need to integrate various printing and control systems? The HERMA 152E wrap-around labeling system offers you the best of both worlds. Despite its compact size, the system covers a wide range of possible product dimensions. In addition to its applications in the pharmaceutical industry, the HERMA 152E is a do-it-all machine for a wide range of industries. With the 152E you get a complete package with superior performance for labeling all sorts of cylindrical products, for instance vials, bottles, canisters and cans.

Request for a quote

HERMA GMBH

Germany

For low-cost labeling solutions The HERMA basic redefines the technical benchmark in its class. Its performance and market positioning are both excellent reasons for deciding for the HERMA technology. Made in Germany, made by HERMA The HERMA basic has genuine HERMA DNA. The processing quality is the accustomed, familiar high standard expected from HERMA. The HERMA basic is manufactured in the same plant in Germany that produces the globally successful HERMA 500 applicator. Reliable, rugged and precise with standard applications The HERMA basic works at a speed of up to 25 m/min: this can be adjusted using the keypad and display. Its integrated controller means there is no need for an additional switch cabinet. Versatile solution to new challenges The HERMA basic is fitted with mounting points that are identical to those of the HERMA 500. If special applications or higher speeds are required, it is easy to switch to the more powerful applicators of the HERMA 500 family.

Request for a quote

HERMA GMBH

Germany

452C - the high-flyer in top labeling: Equipped with the HERMA 500. Precise top labeling on all types of surfaces. Easy to integrate into any kind of production line. Extremely efficient and highly productive. Space-saving, compact and hugely versatile. Easy to integrate printers for variable labeling. Can be combined with the highly reliable 552C bottom labeler.

Request for a quote

HERMA GMBH

Germany

Powerful: Fast set-up thanks to innovative technologies such as motorised liner feed & automatic label length detection. Label at speeds from 30 m/min up to 200 m/min. Networked: State-of-the-art interfaces for tomorrow's machine communication. Industry 4.0-capable thanks to OPC and Ethernet interface as well as configurable fieldbus connection. Web functionality, as well as online registration for fast support, function upgrades & firmware updates. Reliable: Long-term availability of all parts and future-proof interfaces for digital challenges. Comprehensive service worldwide, at your site or in HERMA Online Services. Universal: Whether pharmaceutical, cosmetics, food or other industries - the HERMA 500 is suitable for all sectors thanks to the highest standards in security and quality.

Request for a quoteResults for

Fully automatic labelling machines - Import exportNumber of results

40 ProductsCountries

Company type