- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filament winding

Results for

Filament winding - Import export

OCV ITALIA

Italy

158B Roving is specifically designed for use in filament winding applications using epoxy resin, where high strength is required. 158B is suitable to reinforce phenolic resins. Fast wetout properties and high burst strength maximize customers’ processing and minimize costs.EXCELLENT PROCESSING Smooth runout combined with low fuzz properties, result in smoother parts and less downtime for cleanup, enabling higher efficiencies and lower manufacturing costs. FAST WETOUT Allows the processor to optimize part production speed resulting in increased productivity and reduced costs. HIGH BURST STRENGTH Excellent glass/resin bonding, which provides high burst strength in pipe or vessels. CORROSION RESISTANT Excellent corrosion resistance with Advantex® Glass compared to standard Eglass providing longer service life in applications facing corrosion.

Request for a quote

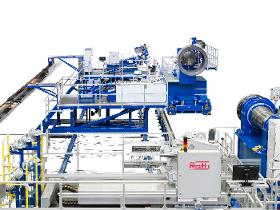

ROTH COMPOSITE MACHINERY GMBH

Germany

•Product development and small-scale production •Small footprint •Enables direct transfer of process parameters to automated capabilities •Highest precision and winding quality

Request for a quote

ROTH COMPOSITE MACHINERY GMBH

Germany

• High-performance series machine • Individual configuration according to customer requirements and process requirements • Can be integrated into production lines for Automation of production • Highest precision and winding quality

Request for a quote

ROTH COMPOSITE MACHINERY GMBH

Germany

•Serial production for large-scale parts •Carriage with maximum precision movable •Several carriages can be realized for additional materials •Highest precision and winding quality

Request for a quote

EC PLAZA

South Korea

1. Foam Filled Fender Foam-filled fenders are constructed with an energy-absorbing foam core and a tough outer skin of filament-reinforced polyurea elastomer. 2. Fender Skin The elastomer used in the fender skin is polyurea. The skin is reinforced by filament winding wrap in a helical and hoop direction, which is controlled by an automatic winding system with load cell sensors at each filament. Our four-axis filament winding system, also used to build spacecraft fuel tanks, takes control and positions each filament for maximum strength and even finish. The polyurea shows far superior physical properties to those of the rubber. The durable and resilient polyurea skin also offers the best resistance to salt water and ultraviolet light. 3. Various colors Standard color shall be made of Dark red, gray and black. But customers can request yellow etc.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OCV ITALIA

Italy

PipeStrand® S2300 is made for fabricators that want to reduce material cost, while increasing the performance of their filament wound products. Designed to increase production efficiency, while providing excellent hydrothermal stability under pressurized conditions. OUTSTANDING MECHANICAL PROPERTIES Excellent properties in both amine and anhydride curing systems; improved axial tensile strength, interlaminate shear strength and burst stress for high performance filament wound epoxy applications. REDUCE COST Designed for use in filament winding, in both epoxy amine and anhydride curing systems — giving flexibility with one glass input and higher glass loading. GREAT STRAND WETOUT Excellent processing range, fast wetting and smooth pipe surface. LONG SERVICE LIFE Excellent hydrothermo stability and strength retention under pressurized conditions, leading to long service life for installed pipe.

Request for a quote

OCV ITALIA

Italy

366 Type 30® Single End Roving is specifically designed for fast wetout, good processing, high glass loading and excellent laminate properties, to maximize customers’ processing efficiency and minimize their production costs in pultrusion and filament winding applications. EXCELLENT PROCESSING Owens Corning T30 does not have catenary, enabling smooth runout, while low fuzz properties result in smoother parts and less downtime for cleanup; enabling higher efficiencies and lower manufacturing costs. OUTSTANDING MECHANICAL PROPERTIES Excellent shear and flexural properties in major resin systems, provide maximum part strength and long part service life. EXCELLENT STRAND WETOUT WITH REDUCED COST Fast, uniform strand wetout leads to higher glass loading with reduced resin, in all major resin systems. Resulting in optimized part production speed and increased productivity, reducing manufacturing costs.

Request for a quote

KARL SCHUPP AG

Switzerland

Tapes made from cotton, shrinkable polyester, fibreglass Cords made from polyester or fibreglass braided or twisted or filled with fibreglass filament End winding lacing tape, banding tape Polyglas ®

Request for a quote

KGA ENCLOSURES LTD

United Kingdom

Product Features: • Primary 115 VAC, 60 Hz. (Except 261D6 and 261GE6 which are 115/230 50/60 Hz.) and (265EES which is 120/240, 50/60 Hz). • Designed for small power or bias supplies, test equipment, preamps etc. • Models 261C6, 261D6, 261E6 and 261G6 can also be used with full wave C.T. rectifiers. • Economical, two hole, channel bracket, chassis mount. • Minimum 5" long leads. • Convenient 6.3 or 12.6 volt filament/auxiliary winding.

Request for a quoteResults for

Filament winding - Import exportNumber of results

10 Products