- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- conveyor components

Results for

Conveyor components - Import export

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Pull cords are used as actuators for operating pull rope emergency stop switches along conveyor belt systems. The pull cord and the accessories required for installation are functionally matched to the pull rope emergency stop switch, taking normative requirements into account. We therefore constantly carry out Pull cord, steel cable, 3mm or 5mm red PVC sheathed Various types of tension springs Anchor hook M10 Anchor hook M12 Anchor hook M8 Turnbuckle M6; 2 eyelets Turnbuckle M6; 1 hook / 1 eye Chain link 6 Eye bolt M12x60 * Eye bolt M12x200 * Eye bolt M12x60 * Clamp bracket, size. 3 5 Clamp egg shaped, size. 3 Clamp egg shaped, size. 5 Thimble Gr. 3 Thimble Gr. 5 Marking plate for rip cord Deflection pulley M10x60, pulley And much more

Request for a quote

FORBO SIEGLING GMBH

Germany

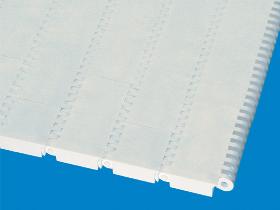

Straight running belts, Pitch 50 mm (1.97 in) Belts for medium to heavy-duty industrial conveying applications Design characteristics -Narrow, closed hinge design -provides high belt pull capacity -Rigid module design makes belt -suitable for long conveyors -Closed solid edge design Components: Sprockets In different sizes with round or square sprocket bore Profiles In different heights and designs for inclines Side guards In different heights for retention of bulk products

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ Belt Scales are ideal for the precise dynamic weighing of raw materials in your process environment. You receive reliable results at affordable prices. Our devices can be used in applications subject to low or high loads, also in rough and difficult conditions. Depending on the application and requirements profile, Belt Scales are available with one, two, or multiple rollers. Advantages and benefits For continuous weighing of a wide range of bulk materials on belt conveyors. Flexible implementation depending on accuracy requirements and actual lay out of belt conveyor. Special solutions for legal-for-trade applications Long term repeatable accuracy due to robust construction and direct load transmission design that eliminates pivots and lever arms Easy installation and alignment with minimum modifications required to existing conveyor structure and components Application Weighbridge Speed sensor Junction box Load cell cable (depending on distance to weighing controller) Integr

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-Vibrating screens are robust, durable, bulk material adapted heavy workers, which are used as discharge units with integrated screening function below a silo, hopper or bunker or as functional organs to feed belts or crushers. Depending on the task, the devices are designed with a robust inlet area with liners (wearing plates) followed by two or three bar grate levels. Each rod is made in a tapered shape which results in a widening gap and bulk jams are avoided. The areas to use such strainers are the primary industry, stones, earth, coal industry with grain sizes up to 1,000 mm in length, but also the chemical and food industry. Everywhere, where a roughly screening and separation of fine and gross material is needed. Advantages & benefits Wide range of applications: product to feed screening of gross grain separation of gross grain before classifying separation of fine grain from crushers protection screening in front of conveyor belts Construction The main components ar

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

Discharging, feeding, conveying AViTEQ reversing conveyors are used wherever bulk solids have to be conveyed and metered in an opposing direction. They are executed as reversing conveyor troughs or pipes. AViTEQ reversing conveyors are used primarily in the food and chemicals industries. Customised solutions, however, can also be realised for the recycling and raw materials industry.The technology used in the magnetic vibrator enables precise metering and exhibits no disruptive start-up or discharge behaviour. Advantages & Benefits mechanical flap and deflection systems eliminated (e.g. Y-fitting) considerably reduced installation height and hence cost saving through lower building costs reversing conveyors also act as shut-off devices the use of magnetic vibrators creates certain benefits (controllability, metering accuracy, no wearing parts etc.) reversing conveyors are available in ATEX design Construction The main components are: reversing conveyors from various materials (e

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-trough conveyor are suitable for conveying and metering of pourable bulk material up to almost any particle size. By ensuring robust and open, trough-shaped structure are particularly suitable conveyors in extreme environmental conditions, because of the easy cleaning ability, but also happy in the chemical and food industry. Advantages & benefits Wide range of applications: using magnetic vibrator drive(s) or vibrator(s) dust-proof versions available long conveying inserted through serial connection possible multiple drive possible execution in mild steel or stainless steel Construction Conveyors are characterized by their simple design. The main components are: conveyor with drive traverse drive in-/outlet pipe (covered variants) elastic support elements flexible seals Selection The sizing is dependent on: bulk material throughput required geometry possible installation mass Key figures length: up to 9,000 mm on single units, theoretically unlimited for conveyor lines

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

The AViTEQ Hopper discharge unit is used below hoppers, silos, bunkers or bulk containers for flowable bulk materials and serves as a combined closure, discharge, transportation and metering device. It is used where high material flows are required. Short hopper discharge units are mounted directly below the bulk hopper. Depending on the bulk material, the discharge unit can be fitted with appropriate protective linear and sealing systems. Advantages & benefits robust design and therefore long-lasting variable feeding speed with magnetic vibrator for optimal dosing to the process bunker closure without additional barriers arrangment central below the bunker run, simple and professional installation possible upon request, in a dust-tight design to save the environment Construction The main components are: conveyor bunker shoe for product guiding inside the feeder drive elastic support elements optional: flexible sealings optional: needle or blade gate for closing Selection The s

Request for a quote

MPN - MECÂNICA DE PRECISÃO DO NORTE, LDA.

Portugal

Containers, conveyors conveyors and components of the recycling industry

Request for a quote

TASK ITALY SRL

Italy

The COMPACT 7-valve filling monobloc is a solution designed for small wineries producing prestigious wines. It can be equipped with a capper for crown caps and dedicated to bottling bottle-refermented craft beer. The central star positions 7 bottles under the taps, which are filled through the tank's descent. While these bottles are capped upon exit, one by one, another set of 7 bottles is positioned under the tank. The semi-annular filling tank made of stainless steel allows the use of nitrogen in the tank. Filling occurs through a slight pressure of inert gas, preventing the dispersion of volatile components. The conveyors are configured so that only one operator is needed. Production: up to 1,000 bph (bottles per hour).

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Discover German engineering at its best with our drive components for conveyor belts. Manufactured from high-quality materials, they guarantee efficient and reliable material movement. Wire Belt offers you guaranteed precision-manufactured sprockets, drive shafts and pulleys. Each component is carefully manufactured in Germany to fulfil the highest quality standards. The durability of our drive components reduces follow-up costs and ensures smooth production processes. Our employees are on hand to advise you throughout the life cycle of every project. Based on your needs, you will receive the best recommendation for the respective material requirements in combination with the motor and the conveyor belts. High standards are essential, especially in the food industry. With Wire Belt you will find the right partner.

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Wire Belt introduces our line of PEEK drive components. PEEK is an abbreviation for PolyEtherEther-Ketone, a high performance engineering thermoplastic that can operate at high temperatures and is less abrasive on your stainless steel belts than metal drive components. PEEK can be used continuously to 250°C and in hot water or steam without permanent loss in physical properties. Our PEEK line is available for all drive components including: sprockets, blanks and end rollers.

Request for a quote

WIRE BELT COMPANY OSTERLOH GMBH

Germany

Wire Belt’s innovative line of Clean-Sweep™ sprockets are specifically designed to deflect the amount of product buildup accumulated on your conveyor’s drive. This means that there is less of a chance for product loss & carryout, belt skipping due to product buildup, and belt breakage due to incorrect contact with the sprocket teeth. Clean-Sweep™ sprocket’s tooth chamfer is machined to reduce drive friction and can lengthen belt life.

Request for a quote

WIRE BELT COMPANY LTD

United Kingdom

When looking for the best conveyor belt drive components for your machine, look no further than Wire Belt’s customised sprockets and blanks. We can guarantee the perfect fit to keep your lines running smoothly and efficiently. Whatever drive component you may be looking for, we offer a variety of materials to meet your needs. To find out more about our solutions, contact our Technical Sales Engineers.

Request for a quote

SIM AUTOMATION GMBH

Germany

Hoppers and belts are the most important part of a production line. While they aren’t used for production themselves, they are a great help in a finely tuned system and significantly optimize the timings. Stop and go is not the watchword, but instead non-stop. Belt hoppers, caches and conveyor belts are all particularly gentle with the product and can be integrated into an existing plant system without any problems. Other advantages of our belt hoppers: - for stock parts for feeding and sorting systems - Extension of replenishment intervals for the operating staff - Dosed allocation of parts - Gentle feeding of parts - Optimization of conveying characteristics on feeder devices - Reduction of feeder device size - Reduction in space needed for part allocation We offer the following small conveyor belts: - With one or two tracks - With deflection rollers or knife edge - With AC/DC motor - Various lengths, scaffolding widths and straps

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

The JETBOXX® mini top-mounted dryers are particularly applicable where small material flow rates with the highest drying precision are required. Due to their compact design, the plastic granulate dryers can be mounted on the feed section of the injection molding machine without any difficulty. The dryers are available with a volume of 0,5/1,0/2,5/5/6/12/18 litres and can be optimally adapted to your requirements with a large number of options from the JETBOXX® system. Compressed air conveyors of one or two components with or without dedusting function are available. Filling by hand is also possible via hinged covers. The compressed air-based dryers are maintenance-free and provide professional functions such as: plastic-specific and throughput dependent dryer settings, database for plastics, conveying control, week timer, overheating protection, dew point measurement, speed dial programs, personal programs, and many more.

Request for a quote

HELIOS GERÄTEBAU FÜR KUNSTSTOFFTECHNIK GMBH

Germany

JETBOXX® plastic granulate dryers are compressed air based dry-air dryers for mounting directly on the feed section of the processing machine. The JETBOXX® technology guarantees perfect drying results thanks to plastic-specific and throughput-dependent dryer settings. The dryers are available with a volume of 30/50/75 litres and can be optimally adapted to your requirements with a large number of options from the JETBOXX® system. The JETBOXX® control provides a database for plastics, conveying control, week timer, fully automatic decrease and resume of the drying intensity when production is interrupted (overheating protection), automatic restart with preheating program in 1- or 2 shift operation, dew point measurement, speed dial programs, personal programs, and many more. Compressed air conveyors of one or two components with or without dedusting function are available. The conveying control is already included.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AQUARIUS GERMANY GMBH

Germany

buckets and round link chain

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

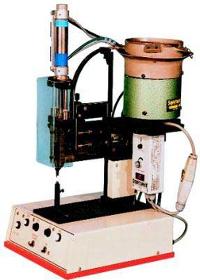

TYP A 040/R Solder lug inserter Description The Streckfuss solder lug inserting device Type A 04 R is designed, to insert solder lugs into p. c. boards. The Solder lugs are automatically moved into the device by a vibrating conveyor. An air cylinder then presses them into the p. c. board. To do this, the p. c. board is to be held manually to the setting position. The setting process by itselve is triggered over an tracer finger. This inserting device is able to process all kind of usual in the trade solder lugs (incl. double tongues), which can be supplied by a conveyor for bulk materilas. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

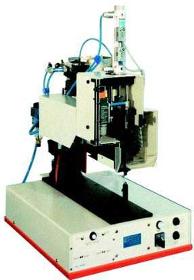

TYP A 042 Round pin inserter Description The Streckfuss inserting device Type A 042 offers the economical solution, for the mechanised insertion of round pins, solder posts and or - lugs into p. c. boards. With this device, nearly all customer forms of round pins, solder posts / - lugs can be processed. The loose components are filled into the sorting pot of the vibration conveyor. Trough barriers in the helical of the conveyor, the components are ordered. After positioning, the components are handed to the loading slider, which supplies the components to the inserting tool. Working with this device is save and easy: For assembling, hold the p. c. board with both hands on the edges, and place it under the inserting tool. The p. c. board now lies at the bottom of the pressure stamp, while the tooling pin hole is placed directly under the solder post / - lug shaft looming out of the inserting tool. This has the function of a locating pin. The p. c. board is lifted parallel, so the components shaft enters the tooling pin hole. The insertion process is triggered by a foot switch. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 067 Cutting, stamping and bending device for radial components Description The Streckfuss machine Type C 067 is designed to process power transistors of types TO 18, TO 92, TO 126, TO 127 and TO 220 with 3 or more radial leads. Also different components (e.g. LED's) can be processed, which fit into the supply- shaft of the machine. The operation of the machine is restricted on filling up the exchangeable feed magazine with components to be processed. Optionally the machine can be equipped with a round- conveyor, to supply loose components automatically to the machine for processing. The tools are equipped with strain relief- valves to eliminate stress to the component body, when the leads are bend and cut. Once formed and cut the component is stored in a collection bin, seperated from shavings. The tool- change for different forms takes less than 5 minutes. Components

Request for a quote

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Quick throughput times, high processing exactness as well as improved working conditions through optimally planned material flow • Compatible components reduce interfaces • Large assortment of standard components: Belt Conveyors: • Curved Belt Conveyors • Small Belt Conveyors • Inclined Belt conveyors Roller Conveyors: • Wheel Conveyors • Light Roller Conveyors • Roller Conveyor Curves • Gravity Roller Conveyors • Driven Roller Conveyors Chain Conveyors: • Chain Conveyors • Traction Lifts Product transportation is an essential element of in-plant logistics. Exact and precise handling is a prerequisite for optimal material flow. Belt conveyors are ideal for transporting light to moderately heavy products. Roller conveyors can be adapted to a variety of space conditions. They are used for transporting light as well as heavy products, are impervious to dust and thus ideal for use in dusty environments.

KÖRBER SUPPLY CHAIN AUTOMATION EISENBERG GMBH

Germany

Advantages • Complete building block system with modular standard components • Individually planned conveyor units, fine-tuned to task requirements • Large assortment of pallet transport technology: • Pallet Roller Conveyors • Pallet Chain Conveyors • Pallet Buffer Conveyors • Pallet Turntables • Pallet Transfer Units • Pallet Shuttle Cars • Empty Pallet Dispensers • Empty Pallet Testers • Pallet Lifts Just some of the tasks for which Langhammer offers the right solution: stacking or separating empty and full pallets, transporting pallets on different transport levels, a wide range of roller conveyors available up to driven roller conveyors with reversible transport direction and high pulling power, driven roller conveyors for lowest building heights, transfer units and turntables enable flexible pallet transport, connect transport lines and change transport direction of the pallet as required.

Results for

Conveyor components - Import exportNumber of results

30 ProductsCountries