- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cold welding

Results for

Cold welding - Import export

IGUS® GMBH

Germany

Other information Series 210 Inner height hi: 21 mm Inner widths Bi: 30 - 120 mm bending radii R: 38 - 200 mm Pitch: 30.5 mm The E4.21 series is identical to 210 series and replaces it. E4.21 - E-Chain® with crossbars at every link Series 220 Inner height hi: 28 mm Inner widths Bi: 40 - 300 mm bending radii R: 55 - 250 mm Pitch: 46 mm E-Chain® with crossbars at every link Series 280 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every link Series 380 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every link Series 400 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 600 Inner height hi: 108 mm Inner widths Bi: 200 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every link Series 640 Inner height hi: 112 mm Inner widths Bi: 87 - 562 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every link Series 290 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every other link Series 390 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every other link Series 410 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 601 Inner height hi: 108 mm Inner widths Bi: 200 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every other link Series R760 Inner height hi: 28 mm Inner widths Bi: 50 - 300 mm bending radii R: 63 - 250 mm Pitch: 46 mm E-Tube, swivel lid Series R770 Inner height hi: 32 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 300 mm Pitch: 56 mm E-Tube, swivel lid Series R780 Inner height hi: 42 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 350 mm Pitch: 67 mm E-Tube, swivel lid Series R880 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R608 Inner height hi: 108 mm Inner widths Bi: 200 - 500 mm bending radii R: 250 - 1000 mm Pitch: 143 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series IPA certificate: Clean room ISO class 3 (DIN 14644-1) at v = 1 m/s for Series 280.10.100.0 tested ESD classification: Electrically conductive ESD/Atex versions on request Other information Series 210 Inner height hi: 21 mm Inner widths Bi: 30 - 120 mm bending radii R: 38 - 200 mm Pitch: 30.5 mm The E4.21 series is identical to 210 series and replaces it. E4.21 - E-Chain® with crossbars at every link Series 220 Inner height hi: 28 mm Inner widths Bi: 40 - 300 mm bending radii R: 55 - 250 mm Pitch: 46 mm E-Chain® with crossbars at every link Series 280 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every link Series 380 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every link Series 400 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every link Series 600 Inner height hi: 108 mm Inner widths Bi: 200 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every link Series 640 Inner height hi: 112 mm Inner widths Bi: 87 - 562 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every link Series 290 Inner height hi: 32 mm Inner widths Bi: 50 - 400 mm bending radii R: 63 - 300 mm Pitch: 56 mm E-Chain® with crossbars at every other link Series 390 Inner height hi: 42 mm Inner widths Bi: 50 - 400 mm bending radii R: 75 - 350 mm Pitch: 67 mm E-Chain® with crossbars at every other link Series 410 Inner height hi: 56 mm Inner widths Bi: 50 - 600 mm bending radii R: 135 - 500 mm Pitch: 91 mm E-Chain® with crossbars at every other link Series 601 Inner height hi: 108 mm Inner widths Bi: 200 - 600 mm bending radii R: 200 - 1000 mm Pitch: 143 mm E-Chain® with crossbars at every other link Series R760 Inner height hi: 28 mm Inner widths Bi: 50 - 300 mm bending radii R: 63 - 250 mm Pitch: 46 mm E-Tube, swivel lid Series R770 Inner height hi: 32 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 300 mm Pitch: 56 mm E-Tube, swivel lid Series R780 Inner height hi: 42 mm Inner widths Bi: 50 - 300 mm bending radii R: 125 - 350 mm Pitch: 67 mm E-Tube, swivel lid Series R880 Inner height hi: 56 mm Inner widths Bi: 75 - 462 mm bending radii R: 150 - 500 mm Pitch: 91 mm E-Tube, swivel lid Series R608 Inner height hi: 108 mm Inner widths Bi: 200 - 500 mm bending radii R: 250 - 1000 mm Pitch: 143 mm E-Tube, swivel lid Assembly tool for E4-series For the practical opening and closing of the E4 series. Big savings in assembly time Assembly tool for E4-series E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Installation instructions Joining, separating and opening of the E-Chain® and E-Tubes. Assembly Instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. System E4/00 E4/00-E-Chain® with 4-piece structure The low-noise E4 chain Further noise reduction with sound dampers (E4/101 series) Wide application range Numerous interior separation options Large accessory kits Widths up to 2000 mm through extension links Snap-open along both sides Max. travel distance: Over 200 m Typical industrial sectors and applications Robotics and handling systems Materials-Handling Technology Refrigeration engineering Construction machinery Machine tools Wood working Any type of machines Semiconductor Clean room applications cold storage houses Welding machines Maritime applications General mechanical engineering etc. IPA certificate: Clean room ISO class 3 (DIN 14644-1) at v = 1 m/s for Series 280.10.100.0 tested ESD classification: Electrically conductive ESD/Atex versions on request

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

The round tubes are manufactured from a coil that is bent and electric resistance welded (ERW). The forming process can be according to EN 10210, which foresees hot forming or cold forming followed by heat treatment, or according to EN 10219, which foresees cold forming without following heat treatments. The finished product is fully killed and welding seam bead is inside and outside trimmed. These products are used to manufacture both welded and bolted structures, in the field of constructions, engineering, industrial constructions, transports, automotive, agricultural machinery and earth moving machinery. The cold finished tubes are particularly suitable for structures at sight or for aesthetical uses, thanks to the surface aspect typical of cold forming. NORMS HOT FINISHED” TUBES EN 10210-1/2 COLD FINISHED” TUBES EN 10219-1/2 INSIDE TRIMMING EN 10217

Request for a quote

BDP MECHANICAL COMPONENTS DEUTSCHLAND GMBH

Germany

Made by cold forging, machining and welding, material stainless steel, sizes 250mm x 50mm x 15mm, weight 0,5kg, annual demand 800pcs

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of all kinds of highly stressed sliding surfaces, especially at low slip speeds or with oscillating movements Surface separation of temperature-stressed threaded connections For stainless-steel connections Advantages and benefits Broad field of application Good wear and corrosion protection Prevents burning-on and cold welding Good pressure absorption capacity No classification marks according to (EG) No. 1272/2008 Prolonged lubrication effect Metal-free For best adhesion, clean contamination and other lubricants from thread and slide surfaces. Best way is to clean mechanically first (for example, with a wire brush) and then with OKS 2610/OKS 2611 universal cleaning agent. Use a brush, spatula or similar to apply evenly a suitable quantity of paste to the head or nut contact surface and to the thread. The paste also acts as a sealant against spray water and condensate. Do not use paste instead of grease and mix only with suitable lubricants.

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

The different kinds of cold drawn tubes ready on stock cover a wide range of applications: COLD DRAWN SEAMLESS AND WELDED TUBES SUITABLE FOR HONING. COLD DRAWN SEAMLESS AND WELDED TUBES INSIDE H8. COLD DRAWN SEAMLESS TUBES FOR SHAFTS. WELDED SMOOTH BORE CYLINDER TUBES INSIDE H9 OR H10. COLD DRAWN SEAMLESS TUBES FOR HYDRAULIC AND PNEUMATIC POWER SYSTEMS. Seamless and Welded Cold Drawn pipes honed or ready for honing; H8, H9 or H10. STEELGRADES AND DELIVERY CONDITIONS COLD DRAWN / HARD (+C acc. EN 10305 / BK acc. DIN 2391) No heat treatment after final cold drawing. COLD DRAWN / SOFT (+LC acc. EN 10305 / BKW acc. DIN 2391) The final heat treatment is followed by a suitable drawing pass (limited reduction of area). STRESS RELIEVED (+SR acc. EN 10305 / BK+S acc. DIN 2391) After the final cold drawing process, tubes are stress relieved in controlled atmosphere in order to reduce work hardening due to the cold forming process. ANNEALED (+A acc. EN 10305 / GBK acc. DIN 2391) After...

Request for a quote

AVK REWAG

Netherlands

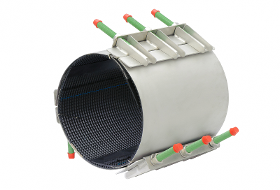

Clamp made out of a pre-rolled plate of stainless steel AISI 316. Design with welded AISI 316 studs and fingers. Clamp equipped with hand grip to simplify installation. Clamp is completely pickled and passivated after welding. Clamp is standard manufactured with BSP thread (other thread on request). Studs are Teflon coated to prevent cold welding (galling). Stainless steel nuts made out of A4 quality. Gasket of NBR rubber with waffle structure and rounded tops. Spanner plate is completely vulcanized into rubber gasket. Diameter reach of single band repair clamp is max. 12 mm (depends on diameter pipe). Clamps available in different diameters: DN 40 up to DN 350. Clamps available in different lenghts: 150, 200, 250, 300, 400, 500 and 600 mm (other lengths on request). Indication pressure class for (waste)water: 16 bar for DN 40 up to DN 150, 10 bar for DN 175 up to DN 300 and 6 bar for DN 350. Indication pressure class for gas: 4 bar for DN 40 up to DN 150, 3 bar for DN 175 up to...

Request for a quote

AVK REWAG

Netherlands

Clamp made out of a pre-rolled plate of stainless steel AISI 316. Design with welded AISI 316 studs and fingers. Clamp is completely pickled and passivated after welding. Studs are Teflon coated to prevent cold welding (galling). Stainless steel nuts made out of A4 quality. Gasket of NBR rubber with waffle structure and rounded tops. Spanner plate is completely vulcanized into rubber gasket. Diameter reach of double band repair clamp is max. 36 mm (depends on diameter pipe). Clamps available in different diameters: DN 250 up to DN 800. Clamps available in different lenghts: 300, 400, 500, 600 and 800 mm (other lengths on request). Indication pressure class for (waste)water: 10 bar for DN 250 up to DN 450, 6 bar for DN 500 up to DN 600, 4 bar for DN 650 and 3 bar from DN 700. Indication pressure class for gas:2 bar for DN 250 up to DN 450, 1, 5 bar for DN 500 up to DN 600, 1 bar for DN 650 and 0,8 bar from DN 700. Studs protected with plastic protection caps.

Request for a quote

AVK REWAG

Netherlands

Clamp made out of a pre-rolled plate of stainless steel AISI 304. Design with welded AISI 304 studs and fingers. Clamp is completely pickled and passivated after welding. Studs are Teflon coated to prevent cold welding (galling) Stainless steel nuts made out of A4 quality. Gasket of EPDM rubber with waffles structure and rounded tops. Spanner plate is completely vulcanized into rubber gasket. Diameter reach of double band repair clamp is max. 36 mm (depends on diameter pipe). Clamps available in different diameters: DN 250 up to DN 800. Clamps available in different lenghts: 300, 400, 500, 600 and 800 mm (other lengths on request). Indication pressure class for water: 10 bar for DN 250 up to DN 450, 6 bar for DN 500 up to DN 600, 4 bar for DN 650 and 3 bar from DN 700. Studs protected with plastic protection caps.

Request for a quote

AVK REWAG

Netherlands

Clamp made out of a pre-rolled plate of stainless steel AISI 304. Design with welded AISI 304 studs (50 mm center to center) and fingers. Clamp is completely pickled and passivated after welding. Studs are Teflon coated to prevent cold welding (galling). Stainless steel nuts made out of A4 quality. Gasket of NBR rubber with waffle structure and rounded tops. Spanner plate is completely vulcanized into rubber gasket. Diameter reach of double band repair clamp is max. 36 mm (depends on diameter pipe). Clamps available in different diameters: DN 250 up to DN 800. Clamps available in different lenghts: 300, 400, 500, 600 and 800 mm (other lengths on request). Indication pressure class for (waste)water: 10 bar for DN 250 up to DN 450, 6 bar for DN 500 up to DN 600, 4 bar for DN 650 and 3 bar from DN 700. Indication pressure class for gas:2 bar for DN 250 up to DN 450, 1, 5 bar for DN 500 up to DN 600, 1 bar for DN 650 and 0,8 bar from DN 700. Studs protected with plastic protection caps.

Request for a quote

AVK REWAG

Netherlands

Clamp made out of a pre-rolled plate of stainless steel AISI 304. Design with welded AISI 304 studs and fingers. Clamp is completely pickled and passivated after welding. Studs are Teflon coated to prevent cold welding (galling). Stainless steel nuts made out of A4 quality. Gasket of NBR rubber with waffle structure and rounded tops. Spanner plate is completely vulcanized into rubber gasket. Diameter reach of double band repair clamp is max. 36 mm (depends on diameter pipe). Clamps available in different diameters: DN 250 up to DN 800. Clamps available in different lenghts: 300, 400, 500, 600 and 800 mm (other lengths on request). Indication pressure class for (waste)water: 10 bar for DN 250 up to DN 450, 6 bar for DN 500 up to DN 600, 4 bar for DN 650 and 3 bar from DN 700. Indication pressure class for gas:2 bar for DN 250 up to DN 450, 1, 5 bar for DN 500 up to DN 600, 1 bar for DN 650 and 0,8 bar from DN 700. Studs protected with plastic protection caps.

Request for a quote

AVK REWAG

Netherlands

Clamp made out of a pre-rolled plate of stainless steel AISI 304. Design with welded AISI 304 studs (50 mm center to center) and fingers. Clamp is completely pickled and passivated after welding. Studs are Teflon coated to prevent cold welding (galling). Stainless steel nuts made out of A4 quality. Gasket of NBR rubber with waffle structure and rounded tops. Spanner plate is completely vulcanized into rubber gasket. Diameter reach of double band repair clamp is max. 36 mm (depends on diameter pipe). Clamps available in different diameters: DN 250 up to DN 800. Clamps available in different lenghts: 300, 400, 500, 600 and 800 mm (other lengths on request). Indication pressure class for (waste)water: 10 bar for DN 250 up to DN 450, 6 bar for DN 500 up to DN 600, 4 bar for DN 650 and 3 bar from DN 700. Indication pressure class for gas:2 bar for DN 250 up to DN 450, 1, 5 bar for DN 500 up to DN 600, 1 bar for DN 650 and 0,8 bar from DN 700. Studs protected with plastic protection caps.

Request for a quote

AVK REWAG

Netherlands

: Clamp made out of a pre-rolled plate of stainless steel AISI 316. Clamp is manufactured with a hinge point in order to simplify installation. Design with welded AISI 316 studs and fingers. Clamp is completely pickled and passivated after welding. Studs are Teflon coated to prevent cold welding (galling). Stainless steel nuts made out of A4 quality. Gasket of EPDM rubber with waffle structure and rounded tops. Spanner plate is completely vulcanized with rubber gasket. Diameter reach of double band repair clamp is max. 24 mm (depends on diameter pipe). Clamp available in different diameters: DN 80 up to DN 600. Clamp available in different lenghts: 200, 250, 300, 400, 500 and 600 mm (other lengths on request). Indication pressure class for water: 16 bar for DN 80 up to DN 150, 10 bar for DN 175 up to DN 450 and 6 bar from DN 500. Studs protected with plastic protection caps.

Request for a quote

AVK REWAG

Netherlands

: Clamp made out of a pre-rolled plate of stainless steel AISI 316. Clamp is manufactured with a hinge point in order to simplify installation. Design with welded AISI 316 studs and fingers. Clamp is completely pickled and passivated after welding. Studs are Teflon coated to prevent cold welding (galling). Stainless steel nuts made out of A4 quality. Gasket of NBR rubber with waffle structure and rounded tops. Spanner plate is completely vulcanized with rubber gasket. Diameter reach of double band repair clamp is max. 24 mm (depends on diameter pipe). Clamp available in different diameters: DN 80 up to DN 600. Clamp available in different lenghts: 200, 250, 300, 400, 500 and 600 mm (other lengths on request). Indication pressure class for (waste)water: 16 bar for DN 80 up to DN 150, 10 bar for DN 175 up to DN 450 and 6 bar from DN 500. Indication pressure class for gas: 2 bar for DN 250 up to DN 450, 1,5 bar for DN 500 up to DN 600, 1 bar for DN 650 and 0.8 bar from DN 700. Studs...

Request for a quote

AVK REWAG

Netherlands

: Clamp made out of a pre-rolled plate of stainless steel AISI 304. Clamp is manufactured with a hinge point in order to simplify installation. Design with welded AISI 304 studs and fingers. Clamp is completely pickled and passivated after welding. Studs are Teflon coated to prevent cold welding (galling). Stainless steel nuts made out of A4 quality. Gasket of EPDM rubber with waffle structure and rounded tops. Spanner plate is completely vulcanized with rubber gasket. Diameter reach of double band repair clamp is max. 24 mm (depends on diameter pipe). Clamp available in different diameters: DN 80 up to DN 600. Clamp available in different lenghts: 200, 250, 300, 400, 500 and 600 mm (other lengths on request). Indication pressure class for (waste)water: 16 bar for DN 80 up to DN 150, 10 bar for DN 175 up to DN 450 and 6 bar from DN 500. Studs protected with plastic protection caps.

Request for a quote

AVK REWAG

Netherlands

: Clamp made out of a pre-rolled plate of stainless steel AISI 304. Clamp is manufactured with a hinge point in order to simplify installation. Design with welded AISI 304 studs and fingers. Clamp is completely pickled and passivated after welding. Studs are Teflon coated to prevent cold welding (galling). Stainless steel nuts made out of A4 quality. Gasket of EPDM rubber with waffle structure and rounded tops. Spanner plate is completely vulcanized with rubber gasket. Diameter reach of double band repair clamp is max. 24 mm (depends on diameter pipe). Clamp available in different diameters: DN 80 up to DN 600. Clamp available in different lenghts: 200, 250, 300, 400, 500 and 600 mm (other lengths on request). Indication pressure class for (waste)water: 16 bar for DN 80 up to DN 150, 10 bar for DN 175 up to DN 450 and 6 bar from DN 500. Studs protected with plastic protection caps.

Request for a quote

AVK REWAG

Netherlands

Clamp made out of a pre-rolled plate of stainless steel AISI 304. Design with welded AISI 304 studs and fingers. Clamp equipped with hand grip in order to simplify installation. Clamp is completely pickled and passivated after welding. Studs are Teflon coated to prevent cold welding (galling). Stainless steel nuts made out of A4 quality. Gasket of EPDM rubber with waffle structure and rounded tops. Spanner plate is completely vulcanized with rubber gasket. Diameter reach of single band repair clamp is max. 12 mm (depends on diameter pipe). Clamps available in different diameters: DN 40 up to DN 350. Clamps available in different lenghts: 100, 150, 200, 250, 300, 400, 500 and 600 mm (other lengths on request). Indication pressure class for (waste)water: 16 bar for DN 40 up to DN 150, 10 bar for DN 175 up to DN 300 and 6 bar for DN 350. Studs protected with plastic protection caps.

Request for a quote

AVK REWAG

Netherlands

Clamp made out of a pre-rolled plate of stainless steel AISI 304. Design with welded AISI 304 studs and fingers. Clamp equipped with hand grip in order to simplify installation. Clamp is completely pickled and passivated after welding. Studs are Teflon coated to prevent cold welding (galling). Stainless steel nuts made out of A4 quality. Gasket of EPDM rubber with waffle structure and rounded tops. Diameter reach of single band repair clamp is max. 12 mm (depends on diameter pipe). Clamps available in different diameters: DN 40 up to DN 350. Clamps available in different lenghts: 100, 150, 200, 250, 300, 400, 500 and 600 mm (other lengths on request). Indication pressure class for (waste)water: 16 bar for DN 40 up to DN 150, 10 bar for DN 175 up to DN 300 and 6 bar for DN 350. Studs protected with plastic protection caps.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AVK REWAG

Netherlands

Clamp made out of a pre-rolled plate of stainless steel AISI 316. Clamp is completely pickled and passivated after welding. Studs are Teflon coated to prevent cold welding (galling). Stainless steel nuts made out of A4 quality. Gasket of NBR rubber with waffle structure and rounded tops. Spanner plate is completely vulcanized with rubber gasket. Diameter reach of single band repair clamp is max. 12 mm (depends on diameter pipe). Clamps available in different diameters: DN 40 up to DN 350. Clamps available in different lenghts: 100, 150, 200, 250, 300, 400, 500 and 600 mm (other lengths on request). Indication pressure class for (waste)water: 16 bar for DN 40 up to DN 150, 10 bar for DN 175 up to DN 300 and 6 bar for DN 350. Indication pressure class for gas: 4 bar for DN 40 up to DN 150, 3 bar for DN 175 up to DN 300 and 2 bar for DN 350. Studs protected with plastic protection caps.

Request for a quote

AVK REWAG

Netherlands

Feature Clamp made out of a pre-rolled plate of stainless steel AISI 304. Design with welded AISI 304 studs and fingers (50 mm center to center). Clamp is completely pickled and passivated after welding. Studs are Teflon coated to prevent cold welding (galling). Stainless steel nuts made out of A4 quality. Gasket of EPDM rubber with waffle structure and rounded tops. Spanner plate is completely vulcanized with rubber gasket. Diameter reach of single band repair clamp is max. 12 mm (depends on diameter pipe). Clamps available in different diameters: DN 40 up to DN 350. Clamps available in different lenghts: 100, 150, 200, 250, 300, 400, 500 and 600 mm (other lengths on request). Indication pressure class for (waste)water: 24 bar for DN 40 up to DN 150, 16 bar for DN 175 up to DN 300 and 10 bar for DN 350. Studs protected with plastic protection caps.

Request for a quote

AVK REWAG

Netherlands

Clamp made out of a pre-rolled plate of stainless steel AISI 304. Design with welded AISI 304 studs and fingers. Clamp is completely pickled and passivated after welding. Studs are Teflon coated to prevent cold welding (galling). Stainless steel nuts made out of A4 quality. Gasket of EPDM rubber with waffle structure and rounded tops. Spanner plate is completely vulcanized with rubber gasket. Diameter reach of single band repair clamp is max. 12 mm (depends on diameter pipe). Clamps available in different diameters: DN 40 up to DN 350. Clamps available in different lenghts: 100, 150, 200, 250, 300, 400, 500 and 600 mm (other lengths on request). Indication pressure class for (waste)water: 16 bar for DN 40 up to DN 150, 10 bar for DN 175 up to DN 300 and 6 bar for DN 350. Studs protected with plastic protection caps.

Request for a quote

AVK REWAG

Netherlands

Clamp made out of a pre-rolled plate of stainless steel AISI 304. Design with welded AISI 304 studs and fingers (50 mm center to center). Clamp is completely pickled and passivated after welding. Studs are Teflon coated to prevent cold welding (galling). Stainless steel nuts made out of A4 quality. Gasket of NBR rubber with waffle structure and rounded tops. Spanner plate is completely vulcanized with rubber gasket. Diameter reach of single band repair clamp is max. 12 mm (depends on diameter pipe). Clamps available in different diameters: DN 40 up to DN 350. Clamps available in different lenghts: 100, 150, 200, 250, 300, 400, 500 and 600 mm (other lengths on request). Indication pressure class for (waste)water: 24 bar for DN 40 up to DN 150, 16 bar for DN 175 up to DN 300 and 10 bar for DN 350. Indication pressure class for gas: 6 bar for DN 40 up to DN 150, 4 bar for DN 175 up to DN 300 and 3 bar for DN 350. Studs protected with plastic protection caps.

Request for a quote

AVK REWAG

Netherlands

Clamp made out of a pre-rolled plate of stainless steel AISI 304. Design with welded AISI 304 studs and fingers. Clamp is completely pickled and passivated after welding. Studs are Teflon coated to prevent cold welding (galling). Stainless steel nuts made out of A4 quality. Gasket of NBR rubber with waffle structure and rounded tops. Spannerplate is completely vulcanized with rubber gasket. Diameter reach of single band repair clamp is max. 12 mm (depends on diameter pipe). Clamps available in different diameters: DN 40 up to DN 350. Clamps available in different lenghts: 100, 150, 200, 250, 300, 400, 500 and 600 mm (other lengths on request). Indication pressure class for (waste)water: 16 bar for DN 40 up to DN 150, 10 bar for DN 175 up to DN 300 and 6 bar for DN 350. Indication pressure class for gas: 4 bar for DN 40 up to DN 150, 3 bar for DN 175 up to DN 300 and 2 bar for DN 350. Studs protected with plastic protection caps.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

We can custom all kinds metal lathe turning parts such as Tube coupling, hose coupling, turning parts, shaft, pipe joint parts, hose connectors & transition connectors, copper machined tube, flange,bushing, knighthead, pedestal, Piston Rod, insert long pin, Dowel Pin, Drive Pin & Rod,ball head bolt, long rod machined parts, long thread tube parts, nonstandard thread bolt & nut,Extension Rod, etc The technics & capabilities for mechanical parts : manual lathe turning,automatic lathe turning, numerical control lathe turning, Drilling, Grinding, Thread rolling, knurs rolling, cutting, cold heading, hot die forging, welding, Riveting, milling, components Assembly, etc. The telorance can reach to +/- 0.02mm, and the surface roughness can reach N6 standard after milling. Lead time for custom metal machining samples is 10days. COC, Test Report, Rohs, plating report, coating reports, is available !.

Request for a quote

SHAKUNT ENTREPRISES PVT LTD

India

Copper coated low alloy wire Smooth wire feeding and arc stability Increase in strength at elevated temperature High resistant to cold cracking Radiographic weld quality

Request for a quote

SHAKUNT ENTREPRISES PVT LTD

India

Copper coated low alloy wire Smooth wire feeding and arc stability Increase in strength at elevated temperature High resistant to cold cracking Radiographic weld quality

Request for a quote

SHAKUNT ENTREPRISES PVT LTD

India

Copper coated low alloy solid wire Uniform copper coating The weld being smooth and shiny is a special characteristic It gives good wetting, rust and scale tolerance Weld is resistant to cold cracking Radiographic weld quality

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

LATERAL BRACKETS TO BE WELDED Straight brackets made of cold-formed sheet steel, fitted with housing for supporting the roller shaft. ADJUSTABLE LATERAL BRACKETS TO BE WELDED Cold-formed steel sheet brackets, comprising a straight bracket fitted with housing for supporting the roller shaft and a plate, connected to it by means of screw and threaded nut, for fastening to the structure by welding.The slots of the junction housings enable precise adjustment of the roller assembly.The choice and dimensions of the brackets to be adopted depend on the diameter of the roller to be supported, the series to which it belongs and the type of installation to be achieved.

Request for a quote

ESAD PANEL INDUSTRIAL COOLING SYSTEMS

Turkey

It is used to prevent heat loss and dust at the doors of Cold Warehouses, even if the door is open. Today, it can be used in every area to create a hygienic environment. It is generally used in cold storage, freezing room entrances, welding and steam sections, production sections and kitchen doors. It provides a hygienic environment by eliminating the problem of pests and flies in the used environment.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

The welding process is one of the core ways in which we manufacture precision tubes. Our high-quality tubing starts off as a flat strip of metal. The strip is formed into a tube through a series of rollers and the join, also called the seam, is then welded together. Welded Processes Special non-destructive testing methods – including eddy current, ultrasonic and pressure testing - are used to ensure a consistent weld. Just like with seamless manufacturing, welded tubes can be drawn down by plug drawing or sinking. This method can be used to create very long lengths of coiled tube, these can also be measured during coiling using a laser measurement. The main welded tube manufacturing processes used are strip welding and cold drawing, but other important processes in between, or at the end of the drawing process, include Please note that we have a minimum order value of £10,000.

Request for a quoteResults for

Cold welding - Import exportNumber of results

61 ProductsCountries

Category

- Tanks, metal (23)

- Copper and copper alloys (3)

- Tools & Hardware (2)

- Bearings - ball, needle and roller (1)

- Disposable medical and surgical articles (1)

- Industrial piping (1)

- Metal structural work (1)

- Mouldings, frame (1)

- Office shelving and filing systems (1)

- Overalls and aprons (1)

- Pipe and tube fittings - ferrous metal (1)

- Pipes and tubes, stainless steel (1)

- Silicones (1)

- Turning - steels and metals (1)

- Valves for industrial fittings (1)