- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- recycling recovery

Results for

Recycling recovery - Import export

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Aluminum separators automatically pick up aluminum and steel cans from all waste collected from the recycling stations. 1. Recovery aluminum cans from plastic bottles. 2. High efficiency of recovery of aluminum from city waste.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

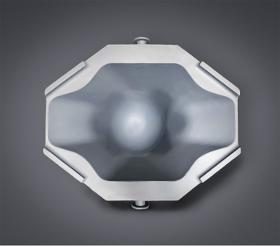

design and manufacture high efficiency aluminum dross recycling equipment for many years, we work with famous American experts in aluminum industry, our main products are dross press, dross pan, cooling head and so on. We have sold our products to NANSHAN, ALBA, ALCOA,DUBAL, HYDRO, KAISER, QATALUM, RUSAL and other famous aluminum companies in the world, our products have obtained high praise from our customers. With unique design, our dross compression unit can cool down the hot dross rapidly, the oxidation and metal loss will be terminated in a very short time. In-house metal recovery could be 30-50%, much higher than any other solutions. We can customize dross press in different types based on your need and your dross amount.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Huan-Tai has been a supplier to the aluminum Industry for over 27 years providing dross pans and sow molds to almost every major aluminum producer in our industry. We supply Aluminum dross recycling unit ingot molds dross pans sow molds cooling slat cake black dross.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Huan-Tai has been a supplier to the aluminum Industry for over 27 years providing dross pans and sow molds to almost every major aluminum producer in our industry. We supply Aluminum dross recycling unit ingot molds dross pans sow molds cooling slat cake black dross.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Huan-Tai has been a supplier to the aluminum Industry for over 27 years providing dross pans and sow molds to almost every major aluminum producer in our industry. We are specialist in designing castings for cooling slat cake and black dross. On average our multi-chamber castings will improve the overall recovery of salt cake and black dross by 20 - 40% or 3 to 4 aluminum percent in the material. We do this by quickly cooling the slat cake and black dross. Mass matters when processing dross. It is the lowest cost and most reliable and lowest maintenance method for cooling salt cake and dross and preserving metal units. Salt Cake and dross pans in the past were typically designed to a thickness of 38 – 40mm. Holding huge quantities of materials that would take anywhere from 18 -24 hours to cool before dumping. Over time they would distort and crack and need periodic replacement. Our High Mass Cooling (HMC) pan design has a minimum thickness of 50 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Recycling recovery - Import exportNumber of results

5 ProductsCountries

Company type