- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- can filling systems

Results for

Can filling systems - Import export

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Longtime Blanc. Molub-Alloy Blanc (05/20/2021) White multi-purpose grease for high bearing pressures and long-term lubrication Description Castrol Molub-Alloy Blanc (previous product name Castrol Longtime Blanc) is a white multi-purpose grease for use at high bearing pressures and long-term lubrication. It is characterized by its special adhesive properties and its water-resistant, sealing properties. Application Molub-Alloy Blanc is used in the food and beverage industry, especially in wet operations, in dusty environments and in conveyor lines, canning and bottle filling systems and labeling machines, where there is no contact between the lubricant and the food or beverage . Molub-Alloy Blanc can be used for long-term lubrication under high pressure loads, vibrations, shock loads, in highly loaded joints, plain and rolling bearings and pipe tracks.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Longtime Blanc. Molub-Alloy Blanc White multi-purpose grease for high bearing pressures and long-term lubrication Description Castrol Molub-Alloy Blanc (previous product name Castrol Longtime Blanc) is a white multi-purpose grease for use at high bearing pressures and for long-term lubrication. It is characterized by its special adhesive properties and its water-resistant, sealing behavior. Application Molub-Alloy Blanc is used in the food and beverage industry, especially in wet operations, in dusty environments and in conveyor lines, canning and bottle filling systems and labeling machines, where there is no contact between the lubricant and the food or beverage . Molub-Alloy Blanc can be used for long-term lubrication under high pressure loads, vibrations, shock loads, in highly loaded joints, plain and rolling bearings and pipe tracks.

Request for a quote

MIROMATIC MASCHINENBAU GMBH

Germany

miromatic – With our experience, we offer you the perfect solution for your requirements. With our individually adaptable machine concepts, tailored to your product requirements, we can fill all fluid to paste-like products. 0.5 l – 30 l buckets Having specialised in tubs, miromatic is now the leading manufacturer in this segment. Bucket sizes from 0.5 l to 30 l can be filled with our systems and they are suitable for products with a great variety of different consistencies – even sticky products. Alongside our core area of competence – hygienic, low-germ and sterile filling, we also offer a broad spectrum of products in the non-food sector. 1.0 l – 25 l canisters Thanks to the experience that we have gathered in the hygienic filling of buckets, we are able to take the logical step of applying our expertise to other large containers. We are the first manufacturer to offer LOG3 category disinfection in the canister sector, whilst also achieving tremendous cycle rates.

Request for a quote

TAPPI STAMPATI S.R.L.

Italy

M60X2 filler neck male threaded, to be screwed, welded on tanks or connected to filling flexible pipes for fuel, hydraulic oils and other fluids. This filler neck is available in different lengths, materials and types. On request we can provide it with removable or fixed filter or complete filling systems with flexible pipes. M60X2 filling system can be combined with our Niches 60 F series or directly with our ALU M60X2 and M60X2 with key threaded caps. Available versions with vent/breather connection and types in stainless steel for nautical applications and corrosive environments. The adoption of accurate production processes also performed with latest generation CNC numerical control machines and the use of selected raw materials, are the first guarantee of quality and reliability over time of our product. We perform several strength and durability tests and tests for product quality control during the various processing phases.

Request for a quote

TAPPI STAMPATI S.R.L.

Italy

AIR fuel tank cap with key in technopolymer and aluminium material, with internal bayonet coupling passage diameter 40 mm and different types of sealing gasket in relation to the fluid in the tank. It is available hermetic or ventilated and it can be equipped with safety chain or cable as well as with removable filter. On request, we can supply it in grey or white color. AIR tank cap is usually sold with our bayonet filling systems passage Ø 40 mm with flange or with our niches series 32–40–50 for connection to flexible fuel hose of different diameters (Ø 32 mm / 40 mm / 50 mm) or with our complete filling systems, that can be customized in relation to specific needs. The additional use of built-in housing for filling caps make easier and very faster the assembling operation of fuel filling systems in the most industrial applications.

Request for a quote

OMS MEKANIK OTOMASYON SISTEMLERI SANAYI TICARET LIMITED SIRKETI

Turkey

Timing cover tightening systems, on the other hand, provide side tightening instead of normal tightening from the top. These cover types are valid for covers that cannot be tightened from above. These types of lids are what we call push type or flush type lids. Regardless of the size of these caps, they are tightened thanks to the silicone pad. Depending on the product cap, it takes between 2000-4000 hours to tighten the cap. When the cap tightening units are alone, they are controlled by the PLC system and 10-7-4.3 HMI screen. It can be added to the filling system when used with the filling line. It can use the same screen with the filling system.

Request for a quote

OMS MEKANIK OTOMASYON SISTEMLERI SANAYI TICARET LIMITED SIRKETI

Turkey

Cap tightening machines are designed to be able to tighten all caps between 10 mm and 50 mm Air system motor is used in cap tightening machines. The systems work with air. 7-8 bar air pressure is needed for the system. According to the condition of the products, a holder can be added for round bottles so that the bottle does not rotate. It can be deactivated in square bottles. Cap squeezing apparatus can be changed according to the bottle cap types. It performs the lid tightening process between 1500-3000 hours depending on the product lid. Cover clamping units are controlled by plc system and 10-7-4.3 hmi screen when they are alone. It can be added to the filling system when used with the filling line. It can use the same screen with the filling system.

Request for a quote

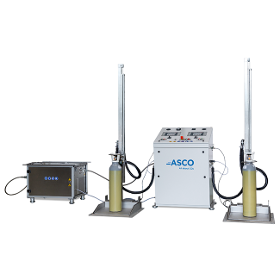

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO LH900 Liquid CO2 Filling Pump has been developed as an universal unit for filling high pressure CO2 cylinders by weight. Like all ASCO Equipment, the Cylinder Filling and Weighing System is thoroughly factory pretested before despatch. Thanks to the separate control unit, the pump can be placed in a different location. Easy operation Switch on your ASCO LH900 and the unit automatically tares itself to „0“ which will show on the indicator display. After placing a cylinder on the platform, the display will show the accurate tare weight of the cylinder, allowing the operator to check whether the empty cylinder weight is correct. The chosen filling weight can now be set on the display by pressing the relevant keys (when filling the same size of cylinder, the filling weight needs only be entered once). When the desired filling weight is reached and displayed, the solenoid valves of the ASCO LH900 will automatically switch to run the system in bypass.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The can weighing and filling machine for liquid, can be both automatic and semi automatic, the automatic one is a inline type and multi heads from 2 heads to 12 heads depends on the capacity demand;the semi automatic one normally is with nonzzles numbers from 1 to 2. Application It is application for Food and beverage, cosmetics and personal care, agricultural, animal care, pharmaceutical, and chemical industries.,Also used in jelly, pudding, fruit juice, ice cream cup filling, yogurt cup filling, honey, curd, buttermilk filling, and shrimpkhand filling with a single or double filling nozzles. It suits for filling multi liquids, low investment, easy cleaning.

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 51 is a semi-automatic filling system that is equipped with both above and below level valves. It is suitable for the precise filling of viscous to pasty liquids, such as paints, varnishes or adhesives, into open containers such as cans and buckets. For liquids that can foam, gas or generate static charges, such as solvents or chemical liquids, the system offers under-level filling, e.g. into canisters. The liquids are fed from storage tanks by gravity or pumps. ■ calibratable filling, both above and below level ■ quick cleaning of the valves (the area in contact with the product consists of 3 parts) ■ Quick changeover to other container dimensions and changing products ■ Simple operation by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Filling station with electronic balance for filling of viscous or pasty liquids, e.g.: paints, varnishes, dispersions, glues, bitumen. For above level filling in coarse and fine flow of standard container types, e.g. open cans, buckets and canisters. Product supply via pump or gravity. Product feed from higher lying storage tanks via natural slope or with the help of pumps. Direct connection via product hoses to the valve. ■ fillings can be calibrated ■ filling valve that eut threads and does not drip ■ quick cleaning of the valve (the valve area in contact with the product consists of 3 parts) ■ very fast cleaning of the container ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ filling, sealing and palettizing by one person ■ the filling station needs only little space ■ immédiate readiness for operation, only connection to energy (electricity and compressed air) and product supply, and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 51 is a semi-automatic filling system that is equipped with both above and below level valves. It is suitable for the precise filling of viscous to pasty liquids, such as paints, varnishes or adhesives, into open containers such as cans and buckets. For liquids that can foam, gas or generate static charges, such as solvents or chemical liquids, the system offers under-level filling, e.g. into canisters. The liquids are fed from storage tanks by gravity or pumps. ■ calibratable filling, both above and below level ■ quick cleaning of the valves (the area in contact with the product consists of 3 parts) ■ Quick changeover to other container dimensions and changing products ■ Simple operation by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Fully automatic filling system with electronic scale for filling liquids which foam, are gaseous or generate static electricity, e.g. detergents/cleaning and car products, solvents, chemical liquids, mineral oils, glazes. For filling open bunghole containers, e.g. canisters. Below level filling coarse/fine, no dripping of the filling material after transfer. Product feed from higher lying storage tanks via gravity or with the help of pumps. Direct connection via product hoses to the valve. The system offers you: ■ an almost foam-free, calibratable below level filling ■ fast and easy valve cleaning (the produkt contact area is made of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the ideal solution for small and medium filling orders ■ simple operation by one person ■ Modular design enables extension by many automatic systems

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

Semi-automatic filling station with electronic balance for filling of viscous or pasty liquids, e.g.: paints, varnishes, dispersions, glues, bitumen. For above level filling in coarse and fine flow of standard container types, e.g. open cans, buckets and canisters. Product supply via pump or gravity. The filling station has the following advantages: ■ fillings can be calibrated ■ filling valve that eut threads and does not drip ■ quick cleaning of the valve (the valve area in contact with the product consists of 3 parts) ■ very fast cleaning of the container ■ quick conversion to other packing sizes ■ perfect for small and medium-sized filling ■ filling, sealing and palettizing by one person ■ the filling station needs only little space ■ immédiate readiness for operation, only connection to energy (electricity and compressed air) and product supply, and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 51 is a semi-automatic filling system that is equipped with both above and below level valves. It is suitable for the precise filling of viscous to pasty liquids, such as paints, varnishes or adhesives, into open containers such as cans and buckets. For liquids that can foam, gas or generate static charges, such as solvents or chemical liquids, the system offers under-level filling, e.g. into canisters. The liquids are fed from storage tanks by gravity or pumps. ■ calibratable filling, both above and below level ■ quick cleaning of the valves (the area in contact with the product consists of 3 parts) ■ Quick changeover to other container dimensions and changing products ■ Simple operation by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

A semi-automatic filling machine with electronic scale for filling liquids which froth, are gaseous or generate static electricity, e.g. cleaning agents, solvents, chemical liquids, mineral oils, glazes. The machine offers you: ■ an almost froth-free, calibratable below Level filling ■ fast cleaning of the valve (the product-contacted area consists of 3 parts) ■ a rapid changeover to other container sizes and changing products ■ the idéal solution for small and medium filling orders ■ simple operation by one person ■ filling capacity up to 6 containers per minute ■ small space requirement ■ immediately ready for use, only energy [electricity and/or compressed air only) and product supply must be connected and filling can be started

Request for a quote

FRICKE ABFÜLLTECHNIK GMBH & CO. KG

Germany

The EFS 12 enables complex control tasks, MES/ERP connections and remote maintenance. Thanks to its modular design, it can be expanded into a fully automatic filling line at any time, including automatic container conveying, capping and labelling. It is suitable for viscous to pasty liquids such as paints and varnishes and offers automatic container transport options as well as an electronic scale. The station supports coarse/fine over-level filling and can be connected directly to storage tanks via inclines or pumps. The system offers you: ■ a calibratable oversize filling system ■ quick cleaning of the valve (the area in contact with the product consists of 3 parts) ■ quick changeover to other container dimensions and changing products ■ Filling, capping and palletising by one person ■ Can be used immediately: just connect the power supply (electricity and/or compressed air) and product supply and filling can begin

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Can filling systems - Import exportNumber of results

17 ProductsCountries

Company type