PARSMEGA MAKINA - Agricultural Machines : Flour Milling Machines Manufacturer

Turkey

Manufacturer/ Producer

PARSMEGA MAKINA

Turkey

It ensures the cleaning of barley, rye, cracked wheat, vetch and black grass seeds in wheat. It performs this cleaning thanks to the sphere-printed sheet metal attached to the body with screws. As this sheet rotates, it separates the materials that will adversely affect the grinding in the incoming product, according to the diameter of the sphere pressure and the spiral angle given by the adjustment lever.

Request for a quote

PARSMEGA MAKINA

Turkey

Radial scanning machine is used to separate low density substances from high density grain products such as wheat, barley, corn and similar. Separates foreign substances such as dust, sand and small seeds in wheat. Wheat entering the machine from the wheat inlet is filled into the vibro feeder and distributed smoothly across the width of the air duct. Here, in the horizontal aspiration channel, the product is separated from low density materials through its double adjustable wall. The fan of the radial scanning machine is mounted on the main body through bearings. The outer body is made of sheet metal, and the foot part and the outlet nozzle located on the foot part are mounted on the body.

Request for a quote

PARSMEGA MAKINA

Turkey

It is used to separate substances such as light grains, husks and dust in wheat with the help of air. Thanks to the vibrating motor at the front, it easily carries out the separation process by spreading the product coming from the flow pipe in the pan.

Request for a quote

PARSMEGA MAKINA

Turkey

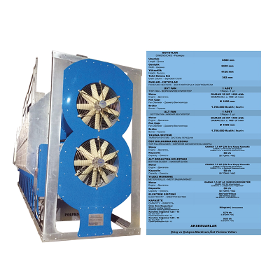

Aspirators have high air suction power and are manufactured in different sizes and engine powers. Aspirators with different capacities; It is frequently used in the aspiration of cleaning machines in Flour Factories. This type of aspirators are also used for the aspiration of low capacity semolina purifiers. They operate at a flow rate of approximately 300 m3/hour. They are generally used in small capacity cleaning units.

Request for a quote

PARSMEGA MAKINA

Turkey

The air duct is made of sheet metal construction. It is possible to make the desired air setting with air valves. Thanks to the mica glass, the cleaning process of the product can be clearly seen. The air duct is used to separate foreign substances that are lighter than the product with the help of air. It is mounted in front of the garbage separator and at the outlet of the peeler. The feeding table located at the product entrance ensures homogeneous goods flow throughout the channel. The rear curtain, which is moved throughout, allows the duct cross-section to be adjusted as desired by means of adjustment bolts. This precise adjustment of the air speed in the duct ensures that the light substances in the grain passing through the duct are separated in the desired amount.

Request for a quote

PARSMEGA MAKINA

Turkey

It ensures the retention of dust and other light substances in the air coming from the cleaning machines. When the air containing dust coming from the dust aspirator is given tangentially to the cyclone, the dust in the air loses its speed as a result of cross-sectional expansion and falls by gravity, while clean air is discharged. Thus, the environmental impact of the air released outside the factory is minimized.

Request for a quote

PARSMEGA MAKINA

Turkey

In flour and semolina factories, it ensures rapid mixing of the product with water and helps shorten the tempering time. Their rotors consist of steel pallets. It is an effective machine in peeling as the grain moves by being squeezed inside the machine.

Request for a quote