PARSMEGA MAKINA - Agricultural Machines : Flour Milling Machines Manufacturer

Turkey

Manufacturer/ Producer

PARSMEGA MAKINA

Turkey

It is used for vertical transportation of wheat. It consists of two parts: lower and upper heading. Pipe length is adjusted according to the building height. The drive of the elevator is made by the reducer motor located on the upper head. The motor stand has slides and can be easily adjusted to enable shaft center adjustments. Belt tension is provided by the tensioning mechanism connected to the bearings.

Request for a quote

PARSMEGA MAKINA

Turkey

In pneumatic systems, it is used to separate air and product and to discharge the product inside the cyclones. The product inside the cyclones enters from the cage part of the machine and product passage is provided through the pockets on the rotor.

Request for a quote

PARSMEGA MAKINA

Turkey

Wheat etc. with different properties through its pockets of different sizes. It is used to mix the products in the desired ratio. There is a table on the machine showing the amount of product that will pass through each gap per hour. It can be entered from a single point or multiple entries can be made from different points of the silo.

Request for a quote

PARSMEGA MAKINA

Turkey

Pneumatic Cyclone Group is a system that moves the spilled product with air flow. The transportation process is carried out in pipes and the transported materials are sent to the Pneumatic Cyclone. Cyclones are made of sheet steel construction. It has a cylindrical-conical body and consists of an inlet and outlet pipe. It is designed to keep the air loss of the system to a minimum during the separation of air and product in the pneumatic system.

Request for a quote

PARSMEGA MAKINA

Turkey

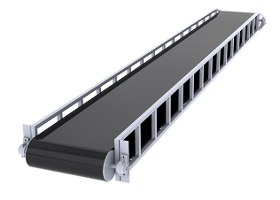

These are conveyors used for general transportation purposes, in the horizontal or inclined transmission of a wide variety of products to different distances. Material transportation in belt conveyors is provided by the belt stretched between the tension drum and the drive drum, which is moved by a motor-reducer system. Belt selection is made according to the type of product to be transported and types such as PVC, polyurethane, rubber and mesh belts can be selected. It is suitable for transporting boxed, bulk and packaged products. It is the conveyor type with the widest usage area, and its usage capacity is also highly variable. Conveyor leg group and chassis are made of Aluminum or electrostatic powder coated steel construction.

Request for a quote

PARSMEGA MAKINA

Turkey

It collects the flour from all exits of the sieve and delivers it to the flour container via pneumatics. Flour inlets are made with separate flour inlet valves. The valves lower the incoming flour into the spiral part. From here, it is directed to the outlet section via a spiral. Since the flour is covered with hair on the spiral, dust formation is prevented. There are ventilation holes at a certain point in this closed sheet metal. The spiral legs are made of rectangular profile. The helix of the gearmotor is located on the side of the outer body and is fixed to this side with the motor stand. There are rubber inspection covers on each flour flap.

Request for a quote

PARSMEGA MAKINA

Turkey

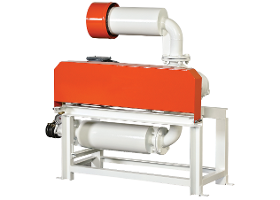

Blower pumps are used in mill systems to meet the air required by the supersonic filter and to transport products vertically and horizontally.

Request for a quote

PARSMEGA MAKINA

Turkey

It is used to give water for tempering in flour factories. It works semi-mechanically.

Request for a quote

PARSMEGA MAKINA

Turkey

It ensures that flour and bran-like products coming out of the machines are returned to the factory.

Request for a quote

PARSMEGA MAKINA

Turkey

Forced annealing; It is used in flour manufacturing facilities to provide high moisture content to wheat in a shorter time and with less water. It is used to give intense and standard tempering to wheat. The wheat to be moistened enters the machine inlet in an automatically controlled manner. Water inlet is controlled by an electronic or mechanical flowmeter. Wheat and water enter the machine at the same time. Provides 5% annealing even at the shortest distance. Forced annealing; It is designed to add (temper) the highest amount of water to wheat. The main bodies, made entirely of metal, are easily removable. The rotor consists of many distributor pallets on it. - Wheat and water are mixed throughout the body thanks to the pallets on the rapidly rotating rotor. With this feature, it performs the annealing process at the desired rate by applying strong rubbing, rubbing and forcing to the wheat. It is possible to reach high capacities with this machine.

Request for a quote