PARSMEGA MAKINA - Agricultural Machines : Flour Milling Machines Manufacturer

Turkey

Manufacturer/ Producer

PARSMEGA MAKINA

Turkey

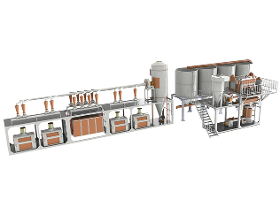

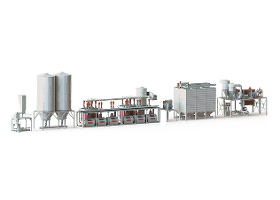

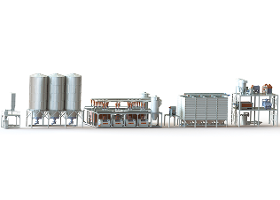

It is a machine that works with a fully compressed air system and is used to turn wheat coming from the cleaning unit into flour in flour factories. The chassis is made of sheet metal construction, and the sub-chassis is completely scanned on the borvek bench to ensure the parallelism of the balls. Rubber wicks are placed under the bed slides to absorb vibration. The properties of the rollers installed on the machine vary according to the diagram and are determined according to the purpose of obtaining the desired flour yield from the factory. All controls on the machine are made with the help of air stimulated valves and there is no electricity consumption. Depending on the amount of incoming product, the valves are stimulated, the pistons close and the grain balls come into action. Thanks to the plate on the grain rolls, the amount of product can be adjusted and flow is provided as a curtain between the roll rolls.

Request for a quote

PARSMEGA MAKINA

Turkey

It is a machine that works with a fully compressed air system and is used to turn wheat coming from the cleaning unit into flour in flour factories. The chassis is made of sheet metal construction, and the sub-chassis is completely scanned on the borvek bench to ensure the parallelism of the balls. Rubber wicks are placed under the bed slides to absorb vibration. The properties of the rollers installed on the machine vary according to the diagram and are determined according to the purpose of obtaining the desired flour yield from the factory. All controls on the machine are made with the help of air stimulated valves and there is no electricity consumption. Depending on the amount of incoming product, the valves are stimulated, the pistons close and the grain balls come into action. Thanks to the plate on the grain rolls, the amount of product can be adjusted and flow is provided

Request for a quote

PARSMEGA MAKINA

Turkey

Control sieve is used in grain production facilities (flour mills, corn factories, etc.) to check the product before packaging. These are facilities with low capacity and space problems with a second purpose of use. Safes can be manufactured as 5 and 10 layers. It can be installed anywhere without any problems. WORKING PRINCIPLE It has its own suspension chassis. Thanks to the chassis, the sieve is mounted on the floor. The chassis on which it is hung has a solid construction. It works with a system driven from the bottom center of the sieve. It is operated by the electric motor mounted on the lower rear part of the machine. The swinging diameter of the sieve can be adjusted with the two-weight drive system.

Request for a quote

PARSMEGA MAKINA

Turkey

Ability to instantly monitor the efficiency of products in factories Ability to monitor the efficiency of products at certain time intervals Precise weighing with stainless steel loadcells PLC based control and data evaluation Ability to monitor all data from the computer Possibility of historical reporting Graphical efficiency reports Ability to add as many scales to the system as desired Efficiency calculation according to input and output Alarm in case of out-of-tolerance measurements

Request for a quote

PARSMEGA MAKINA

Turkey

CAPACITY: Varies between 12 tons/hour and 20 tons/hour, depending on the product to be bagged and the desired tolerance. (It is guaranteed to work with a capacity of 15 tons/hour for flour or products of the same character, with an average error margin of +-50gr. per sack.) SET VALUE: set value can be programmed individually by the user. WEIGHT DISPLAY: The weight display screen has 4 digits. FAST - SLOW CYCLE: There are two programmable set values in the system. And the filling kilos for these values can be entered separately. The slow speed transition program adjustment is automatically determined and adapted by the system to provide the most precise and fastest weighing. Optimum speed adjustment is made automatically according to the weighed flour type and silo level. TOLERANCE: Upper or lower tolerances can be programmed individually. If the weighing result is outside these tolerances, flour is not loaded into the sack from the weighing bunker without

Request for a quote

PARSMEGA MAKINA

Turkey

Measuring the moisture of the flowing raw material with high precision. Calculation of the amount of water to be given according to the desired humidity amount in lt/hour Control of the calculated amount with the electronic water flow meter placed in the system Calculation of faults from the operator panel Instant monitoring of raw material moisture in % Ability to instantly monitor the amount of water given in lt/hour Ability to monitor the amount of water that needs to be given in lt/hour Ability to monitor the total amount of water given in liters. Ability to connect the system to the computer at any time and perform all controls from the computer without having to go near the device.

Request for a quote