- europages

- >

- Transmission elements

- >

- NORELEM FRANCE

- >

- products

NORELEM FRANCE - Leader mondial des composants standard destinés à la construction et à l’ingénierie mécanique

France

Manufacturer/ Producer

NORELEM FRANCE

France

Housing aluminium. Worm screw steel, worm wheel special brass. Version Housing anodised. Ball bearing with rubber sealing washer RS. Note Universally applicable and maintenancefree worm drive in one size with a centre distance of 20 mm and 7 different ratios. The housing is sealed to prevent grease leakage and keep dust out. These are left hand worm gears. The rotation direction on the shaft is arbitrary. smooth power transmission simple screw fastening quiet Note FR permissible radial force at FA=0 FA permissible axial force at FR=0

Request for a quote

NORELEM FRANCE

France

Planetary gearing for stepper motors of the NEMA 23 and NEMA 34 size. Suitable for all mounting positions. Maintenancefree thanks to lifetime lubrication. The planetary gearing is selfcentring, equipped with a flange adapter system and axial length compensation.

Request for a quote

NORELEM FRANCE

France

Zero backlash, torsionally rigid, resiliently flexible and maintenancefree full metal coupling for transmitting angle synchronous rotary movement. The innovative slit structure makes possible a very good axial, radial and angular flexibility with low reset force. Ideal for servomotors. Assembly Recommended shaft tolerances h7. On request Hub bores D1 and D2 with separate tolerance class or range. Note Procedure for enlarging predrilled bores D1/D2 Drill the bore out using a small as possible drill or milling cutter. Use a single point tool to turn or bore the hole out to its finished size. Ensure that the coupling is securely held during the machining process and that the drill feed is not too high. The cut depth should not exceed 0.5 mm and the feed for the single point tool should also be not too high.

Request for a quote

NORELEM FRANCE

France

D1 and D2 are customer specific e.g. 230122025; D1 = 5H7, D2 = 8H7 Note Zero backlash, torsionally rigid, resiliently flexible and maintenancefree full metal coupling for transmitting angle synchronous rotary movement. The innovative slit structure makes possible a very good axial, radial and angular flexibility with low reset force. Ideal for servomotors. Assembly Recommended shaft tolerances h7.

Request for a quote

NORELEM FRANCE

France

Spider polyurethane hardness Shore 98A. Hub aluminium. Conical ring carbon steel. Note This coupling series is particularly suitable for use in high speed main spindle or drill spindle drives. Before the plugin assembly, both clamping ring hubs must be fastened to the shafts with the correct tightening torque. Lightly oil the spider to ease assembly. Assembly The shaft to hub bore fit should be a transition fit. The play should be max. 0.02 mm. i.e shaft Ø 25 k6 bore Ø 25 G6. Bores smaller than D1/D2 min. are possible, however an optimal transfer of the nominal torque is no longer guaranteed. On request Hub bores D1 and D2 with separate tolerance class or range. Drawing reference 1) elastomer spider

Request for a quote

NORELEM FRANCE

France

Centre disc polyacetal. Hub aluminium. Note Clamping the hub with a grub screw is a costeffective alternative to the Oldhamtype couplings with radial clamping hub (23030). Short mounting times. The couplings can be mounted completely assembled or a plugin assembly is also possible. Take note of the tightening torque for the grub screw. To ease removal we recommend milling a flat on the shaft. Assembly The shaft to hub hole fit is a transition fit. The play should be min. 0.01 mm and max. 0.04 mm i.e. shaft Ø 6 f7 hub Ø 6 H8. Advantages robust plugin playfree short design On request Hub bores D1 and D2 with separate tolerance class or range.

Request for a quote

NORELEM FRANCE

France

Steel 1.0718. Stainless steel 1.4305. Version Steel black oxidised. Stainless steel bright. Note Rigid couplings transmit high torques without rotational play. They are used where there are no shaft displacements or alignment errors. Wearfree and maintenancefree. Screws secured to avoid vibration induced loosening. The maximum torque transmission can only be achieved through optimal installation and correct shaft dimensions. Maximum speed 4000 rpm.

Request for a quote

NORELEM FRANCE

France

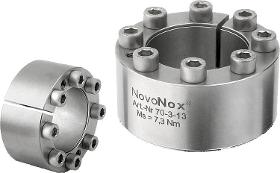

Shrink disc to connect a hollow hub to a shaft. They are mounted on the OD of the hub and generate pressure on the hub wall by reducing the ID with wedgeformed rings, creating a press fit between the hub and shaft. They are suitable for static, dynamic and shock loads. for extremely high torques no axial shaft/hub offset when assembling selfcentring The version 23380014072 has high tensile ISO 4762 screws. Assembly Remove existing transportation locks. Clean and lightly oil shaft, internal and external hub diameters. Do not use MoS2 or grease. Slide shrink disc onto hub. Then slide unit (shrink disc/hub) onto shaft and position correctly. Gently tighten clamping screws one after the other by hand. Then use a torque wrench to tighten the clamping screws crosswise in several increments to the defined tightening torque MS. 1st increment approx. 33% MS 2nd increment approx. 66% MS

Request for a quote

NORELEM FRANCE

France

Particularly compact selfcentring keyless locking coupling without axial offset. for shaft diameters from 8 to 85 mm for medium torques suitable for hubs with low wall thickness no axial offset selfcentring Assembly Lightly oil keyless locking coupling on the tapered faces and contact points of the shaft and hub. Do not use MoS2 or grease. Insert keyless locking coupling in the hub seat and slide onto shaft. Tighten screws crosswise in several increments to the defined tightening torque. Dismantling Remove all screws and screw into the extraction threads of the front flange. Tighten screws crosswise in several steps until the keyless locking coupling loosens. Tolerances Shaft Recommended tolerance h8. Surface quality Rz ≤ 16 µm. Hub Recommended tolerance H8. Surface quality Rz ≤ 16 µm.

Request for a quote

NORELEM FRANCE

France

Coupling stainless steel 1.4057. Screws stainless steel 1.4301. For applications that require a small construction volume and low surface pressure. The keyless locking coupling can be fully recessed in a hub connection. for shaft diameters 6 20 mm suitable for hubs with low wall thickness minimum axial offset possible selfcentring Assembly Lightly oil keyless locking coupling on the tapered faces and contact points of the shaft and hub. Do not use MoS2 or grease. Insert keyless locking coupling in the hub seat and slide onto shaft. Tighten screws crosswise in several increments to the defined tightening torque. Dismantling Remove all screws and screw into the extraction threads of the front flange. Tighten screws crosswise in several steps until the keyless locking coupling loosens. Tolerances Shaft Recommended tolerance h8. Surface quality Rz ≤ 16 µm. Hub Recommended tolerance H8. Surface quality Rz ≤ 16 µm.

Request for a quoteManufacturer/ Producer

5 RUE DES LIBELLULES

10280 Fontaines Les Gres - France