LOUISON INDUSTRIES - TEXTILE & PLASTURGIE

France

Manufacturer/ Producer

LOUISON INDUSTRIES

France

Textile overmoulding has a wide range of applications in various industrial sectors. Our customers in the automotive, electronics, sports, medical and other sectors benefit from our expertise in textile overmoulding to design bespoke parts to meet their specific needs. In the automotive sector: it improves occupant comfort by providing a softer feel. It can also improve soundproofing and thermal insulation. Discover the overmoulded part, a mechanical link between two parts, a textile support and an injected plastic part, in a permanent manner. Overmoulding offers a number of advantages: No gluing stage in the manufacturing process High design flexibility Prevents components from coming loose Production of multi-material components Improved resistance to shock and vibration Improved strength and structure of parts

Request for a quote

LOUISON INDUSTRIES

France

- What type of market? - What choice of raw material? - What technical constraints? - Dimensions: Width up to 1800 mm - Regulations: OEKO-TEX; REACH standard - Finishing : Polyvinyl chloride, polypropylene, PU polyurethane UV resistance, waterproofing, anti-virus and anti-bacteria, anti-abrasive, thermal insulation, fire resistance, etc,

Request for a quote

LOUISON INDUSTRIES

France

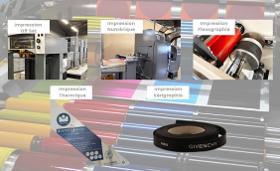

Custom textile label printing solutions Got a project? We offer a made-to-measure service, tailored to your specifications and your needs: Every year, several million labels, tapes and ribbons are manufactured at our production site in Saint-Just-Saint-Rambert. Printing on all textiles: - Printed decorative ribbons and straps - Adhesive or non-adhesive printed labels or not, woven... - Headbands

Request for a quote

LOUISON INDUSTRIES

France

As a state-of-the-art plastic injection moulding company, we guarantee the highest standards of quality. The thermoplastic granules, with a diameter of 2 to 3 mm, are carefully sucked into a hopper and then heated to high temperature. The molten, malleable material is then injected into the mould, selected according to your specifications. Our high-precision injection moulding machines apply high pressure to allow the plastic to spread evenly in the mould, giving it its final shape. In just a few seconds, the part cools and solidifies, ready to be ejected into a recovery bin. Integrating an automated system into our plastic injection process enables us to minimise costs - Weight: Up to 400 g - Texture: Any texture on request - Composition: Polyester, Polyamide, Polypropylene....

Request for a quote

LOUISON INDUSTRIES

France

Discover coextruded tape, used in the building and public works and agriculture sectors as reinforcement in a construction operation (e.g. reinforced earth, tutoring...). A combination of textile and plastic, coextrusion is a process that involves melting thermoplastic resins which then cover the textile in the form of threads (high-tenacity polyester threads, for example). Each material brings its own properties to the product. So, according to the specifications we receive, we will incorporate all the characteristics you need: resistance, texture, etc... Note: the plastic residues generated can be transformed into reusable beads, reducing the overall waste produced during the extrusion process.

Request for a quoteManufacturer/ Producer

ZI du Coin

5 Rue des Echarneaux

42400 St Chamond - France