DDC TEKNOLOJI VE MAKINA SAN. A.S. - Tissue Paper Converting Lines Manufacturer

Turkey

Manufacturer/ Producer

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Combining aesthetics and functionality in toilet paper and kitchen roll production, the 5 Embossed Toilet Paper and Kitchen Roll Machine has a technology that gives extra softness and absorbency to paper products. The embossing process increases both, the visual and tactile quality of the product by adding embossed patterns to the paper surface. If high quality and standard are needed for toilet paper and kitchen rolls, this machine is ideal. The Toilet Paper and Kitchen Roll Machine with 5 Embossings is a production machine that adds special embossed patterns to paper products. This machine adds aesthetic and functional reliefs to the surface of toilet paper and kitchen rolls by using special embossing rollers. These embossings increase the paper’s softness and absorbency, thus improving the product quality. High Quality Embossing Process: it gives an aesthetic and tactile superiority to paper products.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

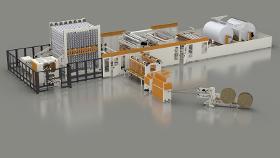

Non-Stop production Line is a technology that revolutionises the production of toilet paper and kitchen towels by offering a continuous and uninterrupted production process. This line significantly improves the efficiency of the production process and product quality with its high speed and continuous operation capability. With its non-stop production capability it enables an impressive production capacity to be achieved, especially in large-scale production facilities. Non-Stop Toilet Paper Line is an industrial line that can operate continuously and produce rolls (toilet paper, kitchen towel) without interruption in production. It maximises the efficiency of the production line and enables more production with less workforce. Continuous operation feature means time and cost savings in production processes. Continuous and Non-Stop Production: Continuous production capability at high speed.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

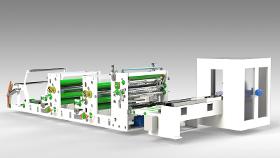

Automatic Mono Toilet Paper and Kitchen Towel Production Line is an efficiency and quality-oriented technology that realises toilet paper and kitchen towel production on a single line. This production line stands out with its high speed and continuous production capability in modern paper production processes. The ability to produce both toilet paper and kitchen towels on a single line simplifies production processes and increases productivity.Automatic Mono Toilet Paper and Kitchen Towel Production Line is a system that can produce both toilet paper and kitchen towels in a single production line. The main feature of this line is that it can produce both products at high quality standards and continuously. In this way, more production can be done in less space. Double Product Production on a Single Line: Both toilet paper and kitchen towel production. High Productivity: Continuous and fast production processes.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

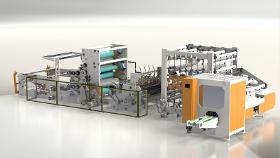

Automatic Dual Toilet Paper and Kitchen Towel Production Line is an advanced technology that offers a high-capacity and efficient production system that occupies an important place in the modern paper production sector. This production line stands out with its ability to produce both toilet paper and kitchen towels at the same time, thus increasing production flexibility and capacity. Equipped with advanced automation features, this line makes production processes faster and more efficient. Automatic (Dual) Toilet Paper and Kitchen Towel Production Line is an automatic production system that can produce toilet paper and kitchen towels at the same time. Thanks to its dual-functional structure, it can produce two different products on the same line and without interruption, which increases both the speed and efficiency of the production process. Dual embossing unit: Ability to produce both toilet paper and kitchen towels.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Automatic Dual Toilet Paper and Kitchen Towel Winding Machine has an important place in the processes of winding the main bobbins into rolls by passing through the embossing and lamination unit. This machine, with its double embossing and lamination system feature, winds with two different embossing techniques at high speed. Offering a continuous and effective solution in paper production, this machine plays an indispensable role in modern production facilities. Automatic Dual Toilet Paper and Kitchen Towel Wrapping Machine is an industrial machine that can wrap products with two different embossing techniques in a single machine and thus meet the demands of different customer groups. Double Embossing Technique: Ability to wrap products with two different embossing patterns. High Efficiency: Fast and uninterrupted production capacity. Flexible Production Options: Ability to process paper of different sizes and thicknesses. User Friendly Design: Easy operation and adjustable features.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

La machine de rembobinage automatique de papier toilette et d'essuie-tout est une machine axée sur l'efficacité et la qualité qui automatise le processus de rembobinage des produits en papier. Cette machine augmente la qualité et la facilité d'utilisation des produits finis en assurant un enroulement précis et régulier du papier toilette et des essuie-tout. Cette machine, qui occupe une place importante dans les installations de production modernes, attire l'attention par sa rapidité et sa capacité de production continue.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

V-fold dispenser napkins, which are frequently used in modern restaurants, cafes and service sector, are produced with high efficiency and quality standards thanks to these machines. V Fold Dispenser Napkin Machine is a machine that packs paper napkins by folding them in a ‘V’ shape. This special folding method allows the napkins to be used easily in dispenser devices and allows them to be removed individually. The machine makes it possible to produce large quantities of napkins particularly quickly and efficiently. Folding Technique: Folds the napkins in a special 'V' shape. High Production Capacity: Suitable for the production of large quantities of napkins. Flexible Production Options: Ability to process master bobbins of different sizes and thicknesses. User Friendly Interface: Easy operation and adjustable functions

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Z Fold Dispenser Napkin Machine is a machine that packs paper napkins by folding them in ‘Z’ shape and makes them suitable for use in dispensers. This folding method allows the napkins to be removed individually and easily, which provides fast and practical use, especially in busy environments. Z-folded napkins are a preferred option in modern service areas and homes by providing ease of use. Highlights of this machine include the following: Z Folding Technique: Folds napkins in a special 'Z' shape. High Production Capacity: Suitable for the production of large quantities of napkins. Flexible Production Options: Ability to process paper of different sizes and thicknesses. Z Fold Dispenser Napkin Machine is frequently used for the production of napkins suitable for quick service restaurants, cafes, hotels and other service sectors Maintenance of the Z Fold Dispenser Napkin Machine is important to keep the machine running efficiently and smoothly.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

Napkin Production Machine is an industrial level machine designed for mass production of napkins. Modern napkin manufacturing machines meet high standards in terms of both quality and efficiency and have a wide range of uses. Napkin Production Machine is an industrial machine used to produce napkins from raw paper material. This machine automatically performs the processes of cutting, folding and sometimes printing the paper. The main purpose of the machine is to meet the demand by producing napkins at high speed and continuously. Fast Production Capacity: Continuous and fast napkin production. Multifunctional Operations: Ability to perform operations such as cutting, folding and printing together. Flexible Production Options: Ability to produce napkins in different sizes and patterns. User Friendly Interface: Easy operation and adjustable functions. Napkin Production Machine is used in places such as napkin producing factories and paper processing plants.

Request for a quote

DDC TEKNOLOJI VE MAKINA SAN. A.S.

Turkey

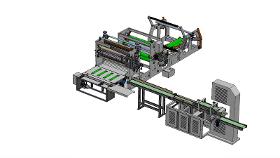

30m/ min Core maker Machine used in the toilet paper industry, plays a critical role in the production of toilet paper and has certain technical features. This machine is capable of high-speed operation, which ensures the ability to produce large quantities of toilet paper cores. It also has a structure that can adapt to different sizes of toilet paper and kitchen towels, which allows the production of various types of toilet paper. The machine is compatible with different bobbin types, making it suitable for the production of soft or hard tubes. Equipped with automatic control systems, this machine enables continuous and efficient operations. The 30M Corer Machine is a machine used in the production of cores and is widely used especially in the paper converting industry. The use of this machine offers great advantages for toilet paper manufacturers. Here is more detailed information on where the 30M Corer is used.

Request for a quoteManufacturer/ Producer

Cerkesli mah. imes 8. cad. no 9 dilovasi

41455 Kocaeli - Turkey