ASP GERMANY - Roboter- Schutzhüllen von ASP Protection

Germany

Manufacturer/ Producer

ASP GERMANY

Germany

Customized protective covers for each type of gripper (X gripper, Z gripper, etc.). Thanks to the modular design of the protective cover, adaptation is quick and simple with cost savings due to partial replacement of the protective device. Different types of fabrics used for optimal protection of each part of the welding gripper. Highly resistant protective robot covers that are silicone-free, halogen-free, non-flammable, quickly mountable and removable, ideal for welding. Access to the gripper preserved: for maintenance operations, the cover can be removed in a flash. Integrated plastron in the cover: optimized protection on the side exposed to heavy spatter With ASP’s CMC gripper cover, you can protect all your welding grippers with a limited number of low-cost items Robot covers reduce maintenance costs for your robot welding grippers Less downtime for protected robots and longer lifespan.

Request for a quote

ASP GERMANY

Germany

Paint stripping by high-pressure water blasting is very aggressive: splash back from jets, paint flakes, etc. For this reason, ASP has developed some original and effective solutions to keep your robot clean and to preserve its condition. Made from coated fabric, ASP’s covers are always the ideal solution for your robot protection problems. They are well-suited to painting processes (silicone free).

Request for a quote

ASP GERMANY

Germany

Many fabrics available based on the robot’s environment and mechanics High tear and abrasion resistance Thermally welded strips on the seams for enhanced waterproofing Custom-fit cover designed to accommodate robot movements Cover available in 1, 2, or 3 parts for easy replacement of worn-out areas Velcro and snap buttons for quick access to the robot’s mechanics

Request for a quote

ASP GERMANY

Germany

To make "window" protective covers, ASP uses dedicated materials that are perfectly compatible with these constraints. The fabrics employed satisfy the strictest requirements (wear, oils, shavings and chips, dust, abrasion, etc.). The covers are made to measure or produced in accordance with the patented FST process. With this process, the lengths of the fabric can easily be optimized to match the robot’s movements, while avoiding excess lengths of fabric, which can often cause tears or malfunctions. Our teams can create suitable metal accessories to keep the covers in position, which guarantees an optimal solution to match your requirements.

Request for a quote

ASP GERMANY

Germany

Damages result in high costs and may potentially lead to production downtime, which can be avoided through the use of high-quality protective covers for robots. Cleaning and maintenance intervals are significantly reduced thanks to robot protection. The robot itself remains clean, and the protective cover combination can easily be cleaned. The customer benefits from easy installation, quick replacement options, and easy cleaning. Additionally, an attractive cost-to-value ratio makes ASP protective covers a wise choice.

Request for a quote

ASP GERMANY

Germany

ASP’s "Forging – stamping" covers use fabrics coated on one or two sides (aramid based). This specific coating provides mechanical and thermal advantages that are needed for these processes (resistance to molten metal splashes, M1 fire protection class, high tear resistance, etc.). Covers that are tailor-made and repaired in our workshop provide the best protection for your robots.

Request for a quote

ASP GERMANY

Germany

Protected seams if needed Workshop or kit repairs if necessary Multiple materials available Covers resistant to moisture, dirt, and extreme temperatures M1-rated fire-resistant fabrics Velcro opening for easy and quick access to robot mechanics Attachment to axis 1 frame allowing free rotation Axis 1 skirt for optimal protection of robot connectors

Request for a quote

ASP GERMANY

Germany

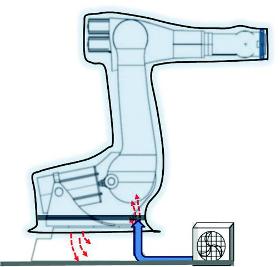

The fan provides a permanent air circulation that keeps the robot dry. The volume of air is renewed preventing moisture from condensing inside the cover.

Request for a quote

ASP GERMANY

Germany

The guarantee of a robot that is fully isolated from the process Ventilation of the cover to eliminate condensation Integration of stainless-steel rotating rings for reinforced sealing Robot protection can be cleaned quickly and easily: smooth, dirt-repellent surface for easy cleaning, even with strong chemicals and high-pressure cleaners. No yellowing of the robot protection cover: The neutrality of the TEXPRAL B+ fabric prevents the cover from yellowing due to exposure to chemical detergents and disinfectants. Lower maintenance costs for industrial robots Reduced downtime for protected robots Protect your expensive machines from wear and tear: protective robot covers can be easily repaired and ordered once our designers have the dimensions and specifications available The seams are protected by heat-sealed tape.

Request for a quote

ASP GERMANY

Germany

ASP’s «ATEX» solutions are made from specific materials and fabricated in compliance with ATEX directive 2014/34/EU. The ground braiding ensures that the cover remains electrically neutral. The «Custom» Design offers maximum efficiency while complying with your constraints and requirements and without restricting robot movement. The ventilation/pressurization option optimizes protection performance. Covers repaired in our workshops provide resilient and long-lasting protection for your robots.

Request for a quoteManufacturer/ Producer

Lebacher Strasse 4 DE - 66113 SAARBRÜCKEN

66113 Saarbrücken - Germany